Gas deep carburizing method for stainless steel

A stainless steel and carburizing technology, applied in the field of deep gas carburizing of stainless steel, can solve the problems of easy cracking, high austenitization temperature, high stress, etc., to avoid cracks, low carburizing temperature, and reduce thermal stress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

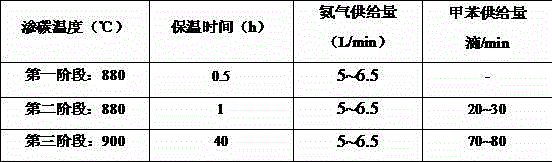

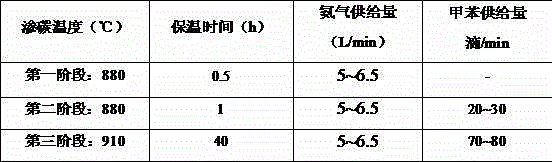

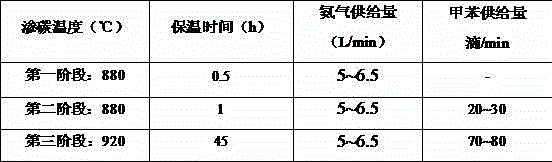

[0055] Embodiment 2 of the present invention. The gas deep layer carburizing method for stainless steel comprises the following steps,

[0056] a. Use 1Cr17Ni2 stainless steel to make parts, clean the parts, and then remove the passivation film on the surface of the parts;

[0057] b. Raise the temperature of the well type carburizing furnace to 880°C, add carburizing agent toluene and infiltrating agent ammonia, the supply rate of toluene is 30-40 drops / min, the supply rate of ammonia gas is 5-6.5 liters / min, and the supply time is 0.5 -1.5 hours;

[0058] c. Put the parts into the well-type carburizing furnace, only supply ammonia gas, and the ammonia gas supply rate is 7.5-8.5 liters / minute. When the temperature of the carburizing furnace reaches 880 ° C, carburizing is carried out:

[0059] The first stage: the furnace temperature is 880°C, the temperature is kept for 0.5-1 hour, and the supply of ammonia gas is 5-6.5 liters / minute;

[0060] The second stage: Furnace te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com