A Rare Earth Implantation Treatment Method for Improving Vacuum Carburizing Efficiency

A technology of vacuum carburizing and treatment method, which is applied in the field of surface treatment combined with ion implantation and vacuum carburizing, can solve the problems of coarse carbides in the carburizing layer, long carburizing cycle, uneven dispersion, etc., and achieves improved vacuum carburizing. Efficiency, uniform distribution, effect of reducing carburizing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0029] Specific implementation mode 1: This implementation mode is carried out with reference to the conventional vacuum carburizing process. Grinding, polishing and cleaning the samples in sequence, the specific implementation steps are as follows:

[0030] 1. Use 60#, 240#, 600#, 800#, 1000#, 2000# sandpaper to polish the surface of the substrate sample smoothly, and clean it with absolute ethanol after polishing;

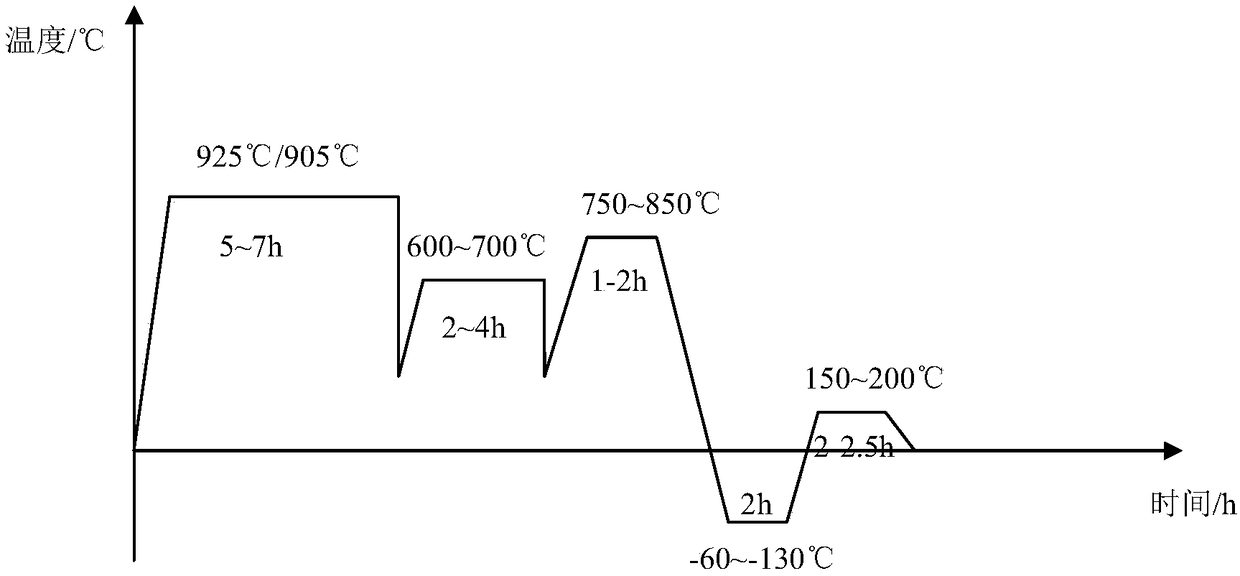

[0031] 2. Put the polished matrix test block obtained from the test into the ECM vacuum carburizing test furnace, close the furnace door, set the carburizing mode to gas pulse type, vacuum the paper in the furnace, and follow the carburizing gas-cooling gas-carburizing Carburize the sample in the order of carbon gas-cooling gas, and the carburizing medium is acetylene (C 2 h 2 ), the cooling gas is nitrogen (N 2 ), the carburizing temperature is 925°C, and the flow rate of acetylene is 1000-2000m 3 / h. The purity of the gas used for carburizing and diffusion...

specific Embodiment approach 2

[0033] Embodiment 2: The rare earth target used for ion implantation in this embodiment is a rare earth Ce target with a purity of 99%. 1.

[0034] The composite treatment method of rare earth Ce implantation combined with vacuum carburizing technology to improve carburizing rate is realized in the following steps:

[0035] 1. Use 60#, 240#, 600#, 800#, 1000#, 2000# sandpaper to polish the surface of the substrate sample block smoothly, and clean it with absolute ethanol after polishing;

[0036] 2. Use the MEVVA DC linear ion implanter to conduct the rare earth Ce ion implantation test. The specific parameters are: the control injection voltage is 40-60KV, and the injection metering is 2×10 17 ion / cm 2 , the implantation temperature is 25-100°C, and a Ce ion implantation layer is obtained on the surface of the alloy steel;

[0037]In the second step, after the test block is placed in the DC linear ion implantation system, the chamber needs to be evacuated, and the target s...

specific Embodiment approach 3

[0040] Specific implementation mode three: In this implementation mode, the samples that are polished, polished, and cleaned without any pretreatment process are subjected to low-temperature vacuum carburizing heat treatment. The specific implementation steps are as follows:

[0041] 1. Use 60#, 240#, 600#, 800#, 1000#, 2000# sandpaper to polish the surface of the substrate sample smoothly, and clean it with absolute ethanol after polishing;

[0042] 2. Put the polished matrix test block obtained from the test into the ECM vacuum carburizing test furnace, close the furnace door, set the carburizing mode to gas pulse type, pump the furnace to vacuum, and follow the carburizing gas-cooling gas-carburizing Carburize the sample in the order of carbon gas-cooling gas, and the carburizing medium is acetylene (C 2 h 2 ), the cooling gas is nitrogen (N 2 ), the carburizing temperature is 905°C, and the flow rate of acetylene is 1000-2000m 3 / h. The purity of the gas used for carbu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com