Rare earth carburizing process using rolling furnace to treat screws

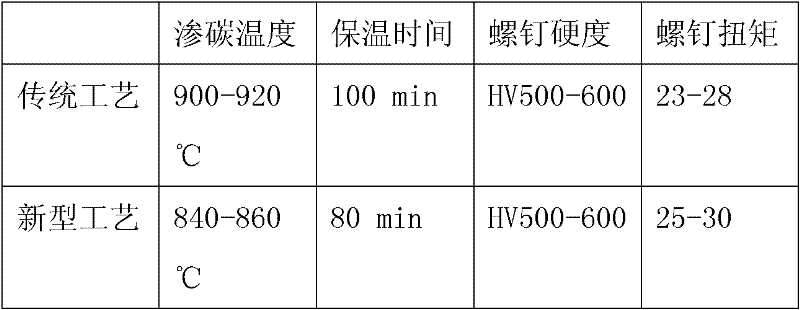

A screw and carburizing technology, applied in the field of metal surface carburizing treatment, can solve the problems of high equipment maintenance rate, long process time, low productivity, etc., and achieve the effect of reducing equipment maintenance rate, simple operation and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The rare earth carburizing process of screws is treated with a rolling furnace, which specifically includes the following steps:

[0016] (1) Configuration contains 0.2g / L cerium chloride, 0.3 / L lanthanum chloride aqueous solution, above-mentioned solution is stirred into refractory soil, is kneaded to ball, control contains 0.02g cerium chloride, 0.02g cerium chloride, 0.03 g of lanthanum chloride;

[0017] (2) Remove the oil on the surface of the screw;

[0018] (3) Put the screws into the rolling furnace, add 40-50 kg of screws for every 40-50 kg of screws, put in 2-3 refractory soil pellets equivalent to 100 grams, and under the protection of nitrogen, feed the carbon generated by the combustion of liquefied gas into the screws Inside, the temperature in the furnace is required to be 840-860 ° C, and the temperature is kept for 80 minutes;

[0019] (4) After the heat preservation in step (3), pour the screws in the rolling furnace into cold water, take them out of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com