Low temperature carburization method of hot-working die steel

A technology of hot work die steel and low temperature carburizing, applied in the direction of coating, metal material coating process, solid diffusion coating, etc. Low, easy to operate, good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

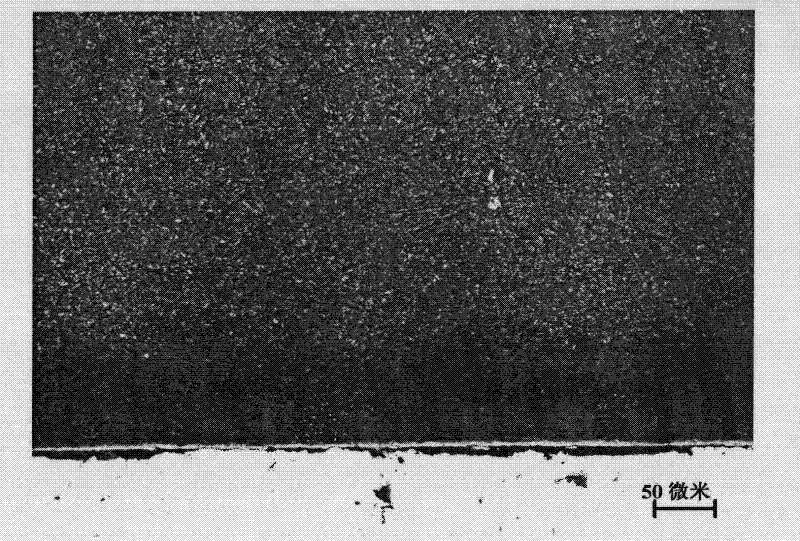

[0035] Example 1 - Low temperature carburizing of hot work die steel HM1 → quenching and tempering → ion nitriding treatment

[0036] Hot work die steel HM1 is a new type of hot work die steel with good high temperature strength. HM1 composition grade is 3Cr 3 Mo 3 W 2 V, the steel contains four carbide-forming elements of Cr, Mo, W, and V. According to the mass content of the carbide-forming elements in HM1, the calculated molar content is about 8.6%. By consulting the material manual, it is known that the Ac1 temperature of HM1 is 850°C, and the supply state is spheroidized annealed structure (ferrite + granular carbide).

[0037] (1) First cut the sample into a size of Φ10×10mm, clean it with ultrasonic waves in 10wt.% NaOH solution for 20 minutes, then wash it with 8wt.% hydrochloric acid for 5 minutes, and finally dehydrate it with alcohol and place it in an oven below 120°C Dry and set aside.

[0038] (2) When the temperature of drip injection well type carburizing ...

Embodiment 2

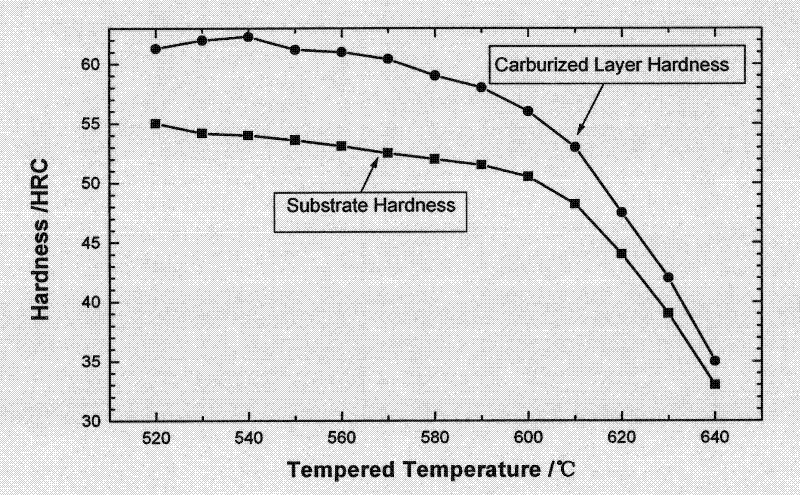

[0044] Example 2 - Low-temperature carburizing of hot work die steel H13→quenching and tempering→soft nitriding treatment

[0045] Hot work die steel H13 is a widely used hot extrusion die for aluminum profiles, and its component grade is 4Cr 5 MoSiV1, the steel contains four carbide-forming elements of Cr, Mo, W, and V. According to the mass content of the carbide-forming elements of H13, the calculated molar content is about 7.2%. By consulting the material manual, it is known that the Ac1 temperature of H13 is 850°C, and the supply state is spheroidized annealed structure (ferrite + granular carbide).

[0046] (1) First cut the sample into a size of Φ10×10mm, clean it with ultrasonic waves in 10wt.% NaOH solution for 20 minutes, then wash it with 8wt.% hydrochloric acid for 5 minutes, and finally dehydrate it with alcohol and place it in an oven below 120°C Dry and set aside.

[0047] (2) When the temperature of the drop-injection well-type carburizing furnace reaches 650...

Embodiment 3

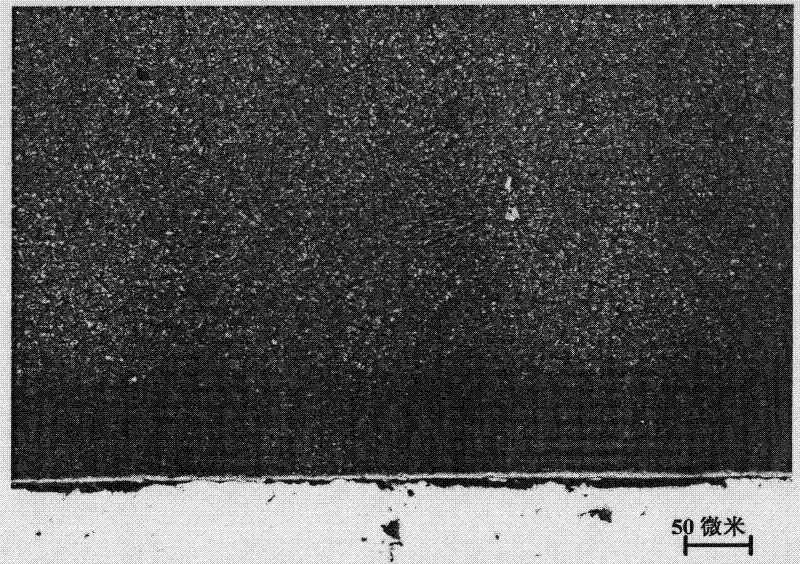

[0053] Embodiment 3 - Low temperature carburizing→quenching and tempering treatment of hot work die steel 3Cr2W8V

[0054] Hot work die steel 3Cr 2 W 8 V is the most widely used upsetting die and die-casting die steel for a long time. The steel contains three carbide-forming elements of Cr, W and V. According to the mass content of the carbide-forming elements of 3Cr2W8V, the calculated molar content is about 6%. . By consulting the material manual, it is known that the Ac1 temperature of 3Cr2W8V is 830°C, and the supply state is spheroidized annealed structure (ferrite + granular carbide).

[0055] (1) First cut the sample into a size of Φ10×10mm, clean it with ultrasonic waves in 10wt.% NaOH solution for 20 minutes, then wash it with 8wt.% hydrochloric acid for 5 minutes, and finally dehydrate it with alcohol and place it in an oven below 120°C Dry and set aside.

[0056] (2) When the temperature of the drop-injection well-type carburizing furnace reaches 650 °C, put the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com