Nitriding and carburizing method by thermal airflow jetting heating and squeezing

A technology of hot gas flow and nitriding, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of high cost, long cycle, large consumption, etc., to improve the precision of parts and reduce the carburizing temperature , The effect of reducing the amount of deformation of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

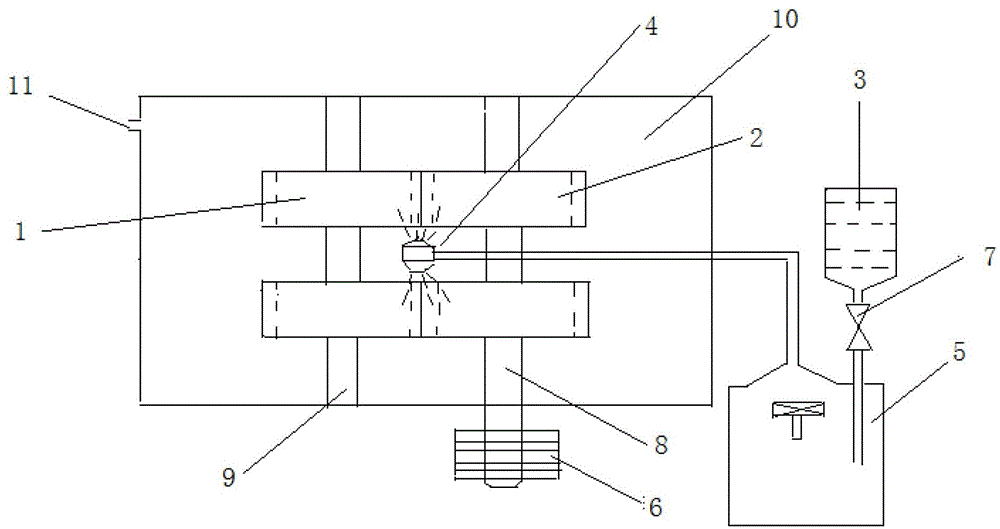

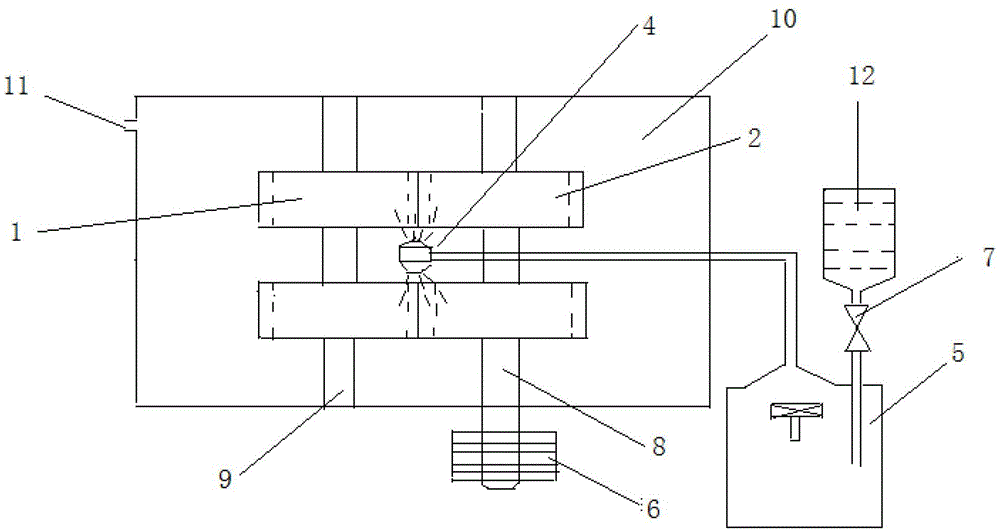

[0042] Below in conjunction with accompanying drawing and technical scheme, take gear processing as example, the present invention is described in detail:

[0043] From the basic principles of material science and metallurgy, it can be known that through extrusion, the crystal lattice of metal materials is deformed, and a large number of vacancies, gaps, atomic loose regions, dislocations, dislocation barriers, and subgrain boundaries are generated inside the crystal. Crystal defects, these crystal defects are not only channels for nitrogen atoms to enter the permeated layer, but also a gravitational field will be generated around these defects to attract nitrogen atoms. This will be an important environment required for low temperature, rapid nitriding or carburizing.

[0044] The present invention is based on the above principles, such as figure 1 figure 2 As shown, a kind of extruding device is provided, and it comprises a sealing box 10, is provided with first rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com