Thermal insulating pipe shell for liquefied natural gas pipeline

A technology for liquefied natural gas and pipeline insulation, which is applied in the direction of pipeline protection, heat preservation, and pipeline protection through heat insulation. It can solve the problems of unfavorable insulation pipe shell disassembly and reuse, affecting heat preservation effect, and inconvenient construction, so as to improve the reuse rate, Easy to disassemble and easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing of description, the present invention will be further described.

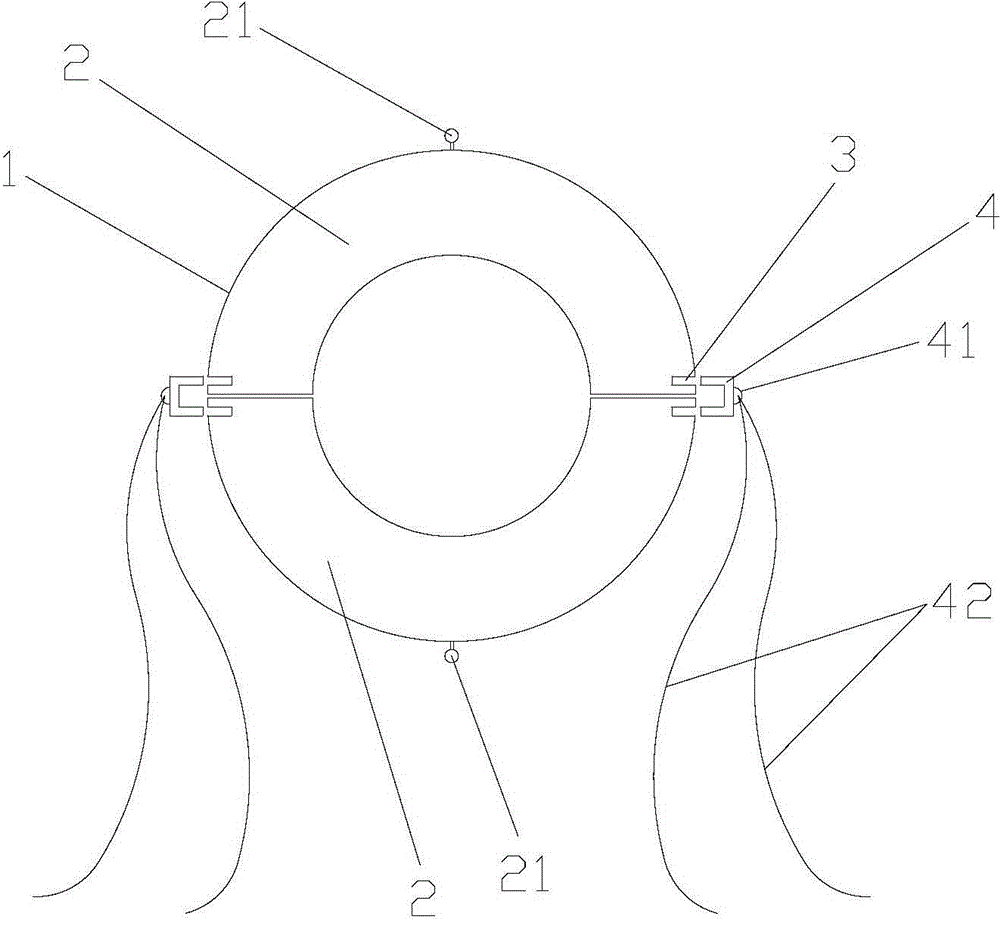

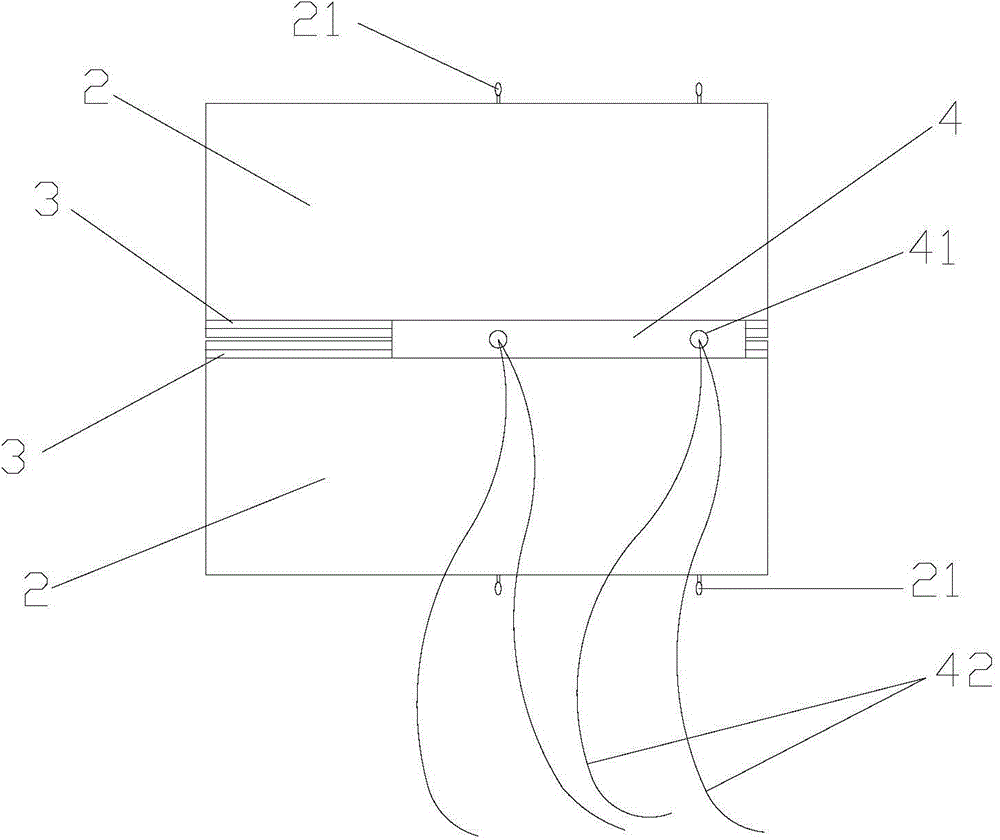

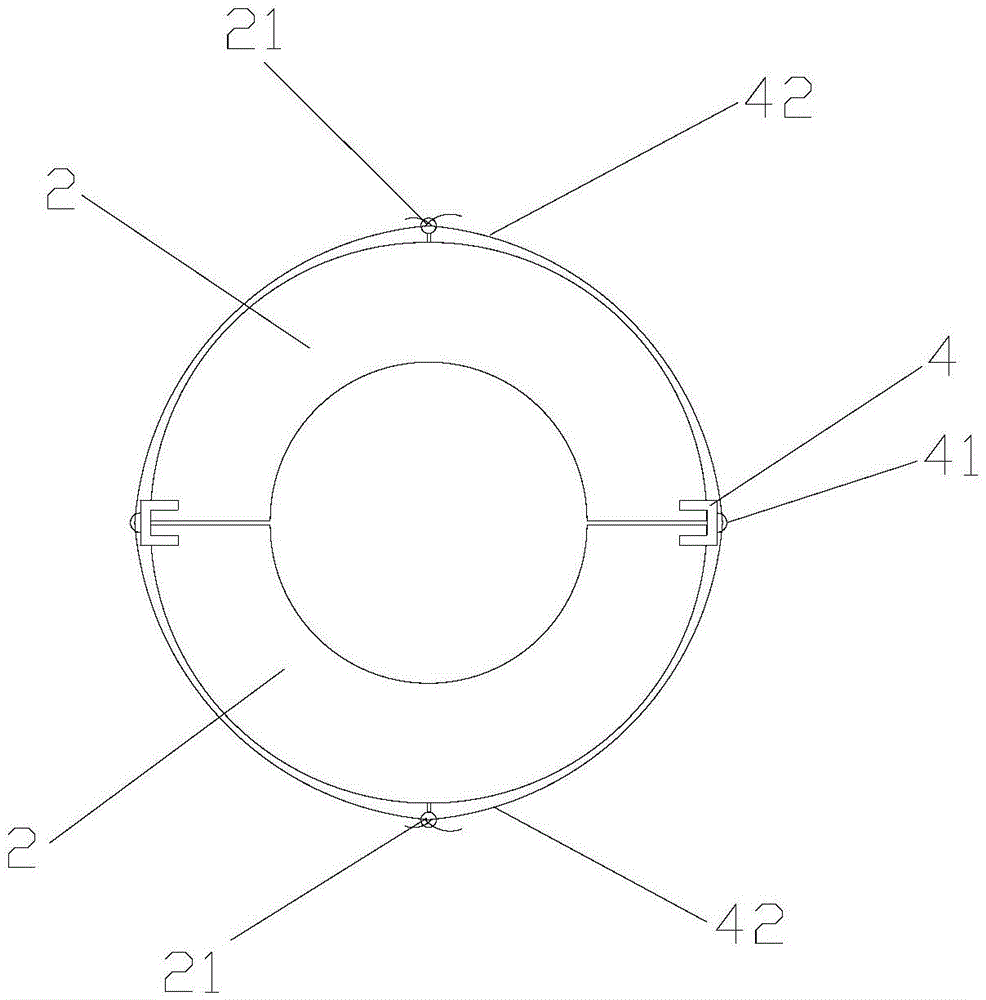

[0024] Such as figure 1 , figure 2 and image 3 As shown, a liquefied natural gas pipeline insulation shell, including a shell body 1 with a hollow cylindrical structure, the shell body 1 includes two half-shells 2 with the same structure, and the outer surface of the half-shells 2 A slot 3 is provided in the axial direction; a filling strip 4 is also included, and the filling strip 4 is a U-shaped structure that is matched and inserted into the slot 3 on the same side of the two half-shells 2 . The slot 3 is parallel to the liquefied natural gas pipeline, that is, the axial directions of the two are consistent.

[0025] The outer surface of the filling bar 4 is provided with a locking ring 41, and the locking ring 41 is connected with a rope member 42 for fixing the two half shells 2; Distributed at intervals in the direction; the rope members 42 are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com