On-line estimation system and method for gas-phase copolymerization impact-resistant polypropylene quality indexes

A quality index, polypropylene technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of bounded deviation of the inference model, unknown statistical characteristics of external disturbances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

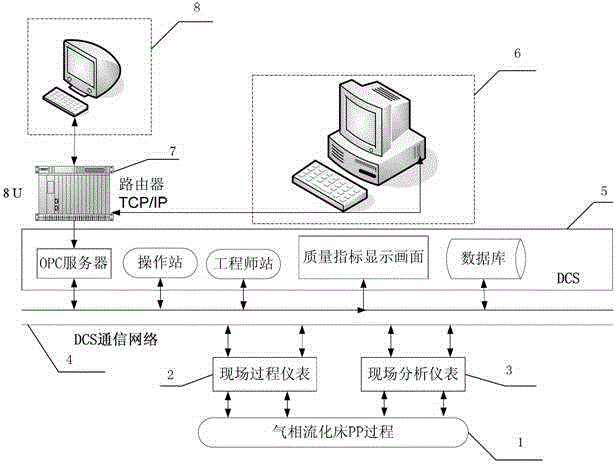

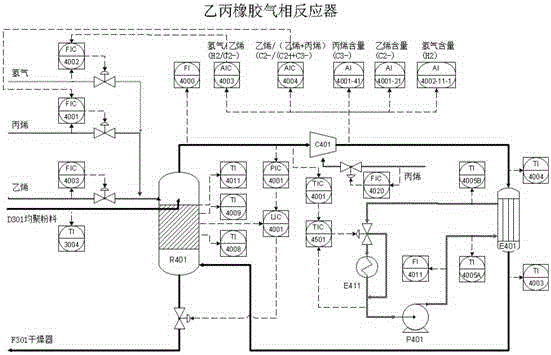

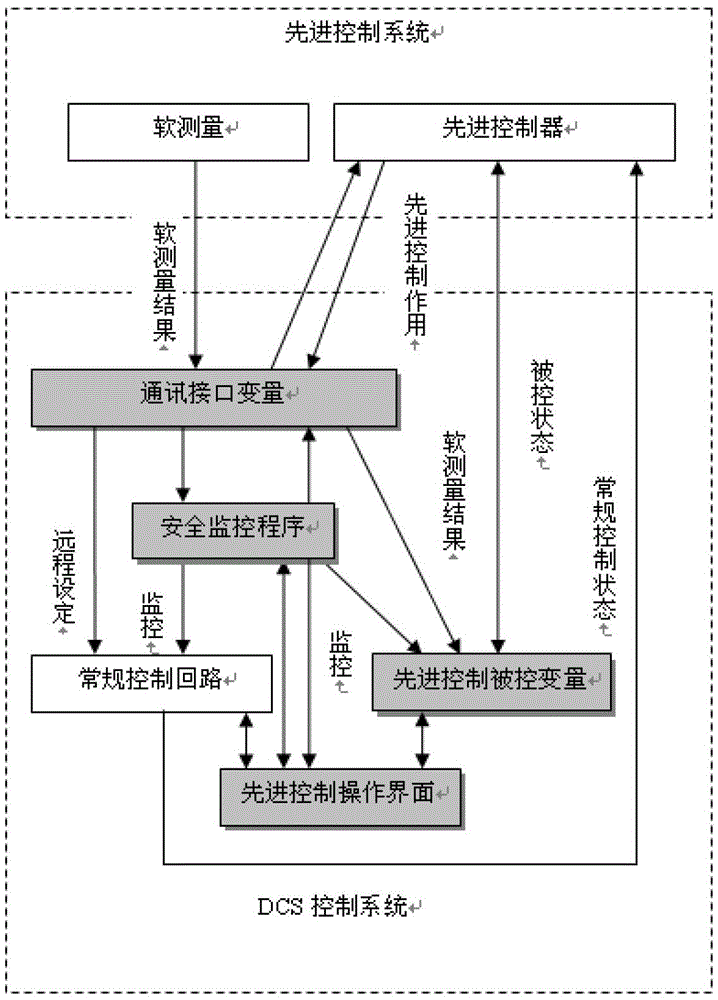

[0070] The present invention is applied to polypropylene production equipment, and the technical process of the equipment is referred to image 3 . The device adopts the Spheripol-II generation polypropylene technology of Italy Basell Company, and was completed and put into production in October 2006. The designed production capacity of the device is 300,000 tons / year of polypropylene granules, and the annual operation is 8,000 hours. It can produce homopolymers (56 grades), random copolymers (21 grades), and impact copolymers (26 grades). There are 103 product grades, covering a wide range of product uses and advanced technical indicators. The device consists of raw material refining, pre-polymerization and loop reactor bulk absolute polymerization, polymer degassing and recovery of propylene and hydrogen, gas phase copolymerization, polymer steaming and drying, additives and extrusion granulation, product blending and Homogenization, air transport and storage units. refer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com