Gas phase polyethylene device quality index and operational constraint on-line estimation system and method thereof

A quality index, polyethylene technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of difficult long-term operation, difficult to adapt to brand switching, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

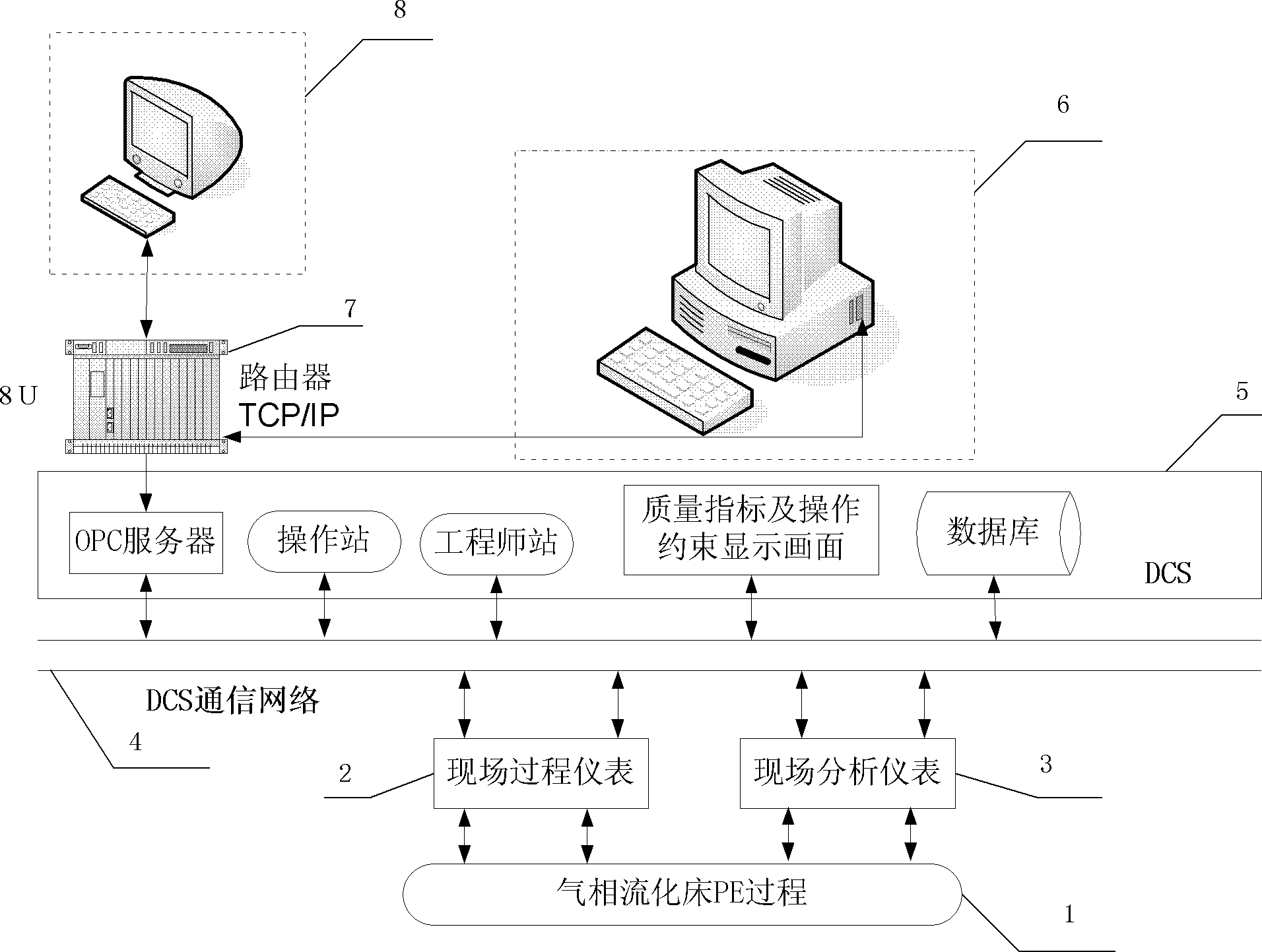

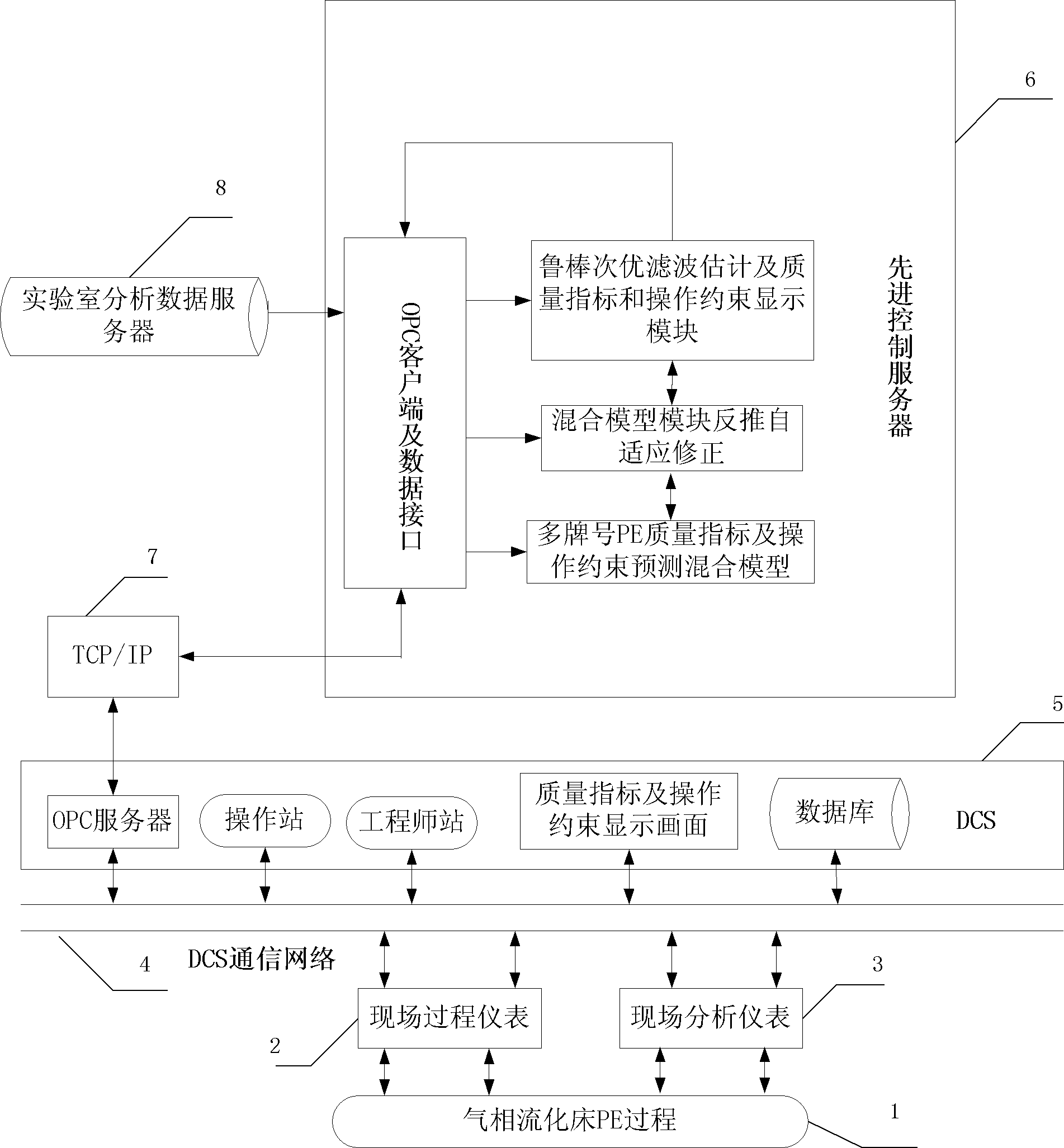

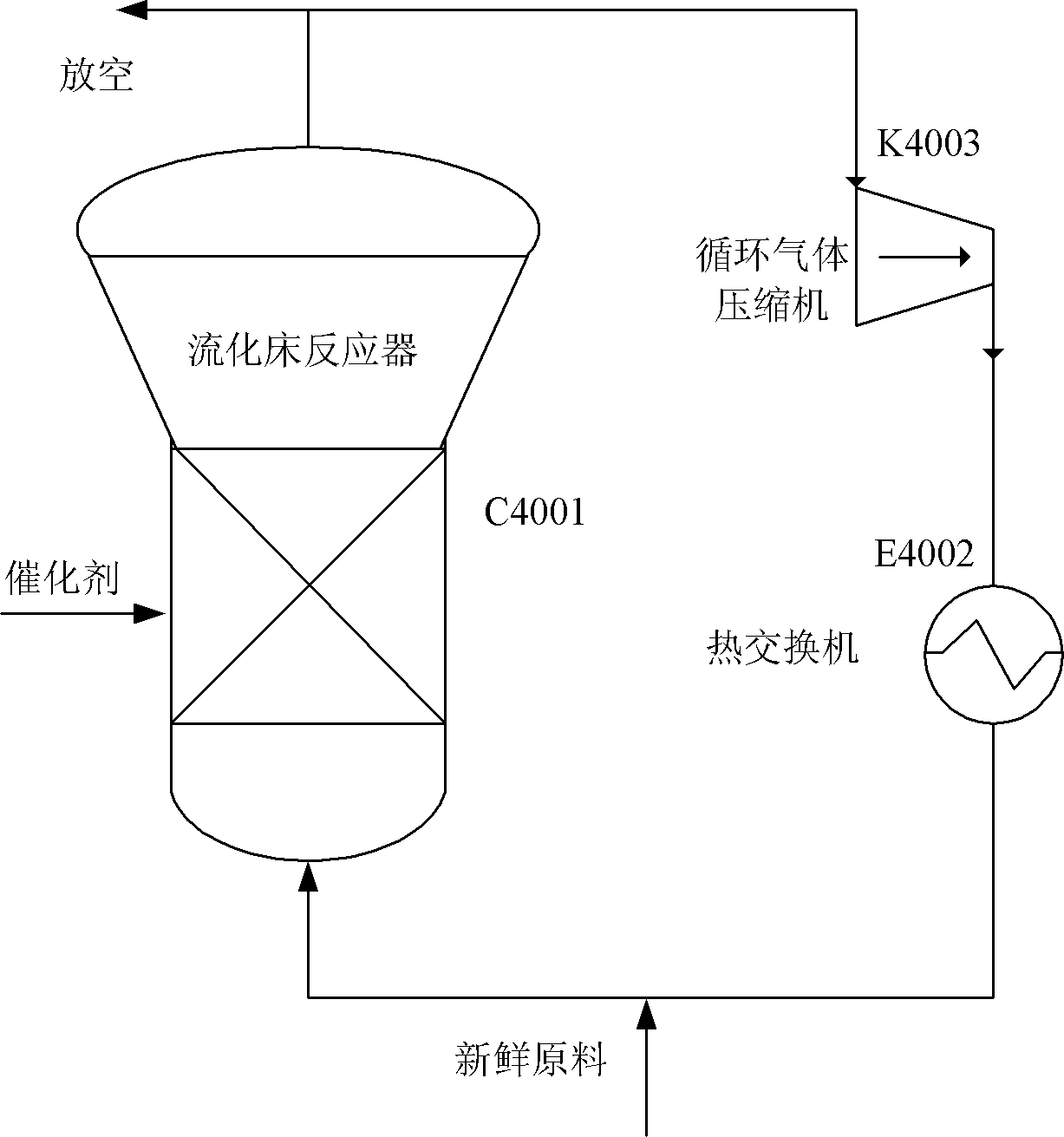

[0103] Apply the present invention to a linear low density polyethylene (LLDPE) production unit, the device process flow is with reference to image 3 . The device adopts the low-pressure gas-phase polyethylene process technology of United Carbon Corporation. The device is composed of raw material refining, polymerization reaction, resin degassing, tail gas recovery, additive treatment, granulation, air delivery and packaging. The original design capacity was 100,000 tons / year of polyethylene resin. After the third-phase transformation, the current production capacity of the device has been expanded to 274,000 tons / year. refer to figure 1 , figure 2 , an on-line estimation system for gas-phase polyethylene plant quality indicators and operational constraints, including field instruments connected to the LLDPE plant, Honeywell TDC3000DCS system (where the APP Node is used as the OPC Server), the database of the laboratory analysis data server is the PI database and the ethyl...

Embodiment 2

[0112] The present invention is applied to the gas-phase method polyethylene multi-brand industrial pilot test evaluation device, and the process flow of the production device is referred to Figure 16 . The multi-brand industrial pilot test evaluation device is used to evaluate the performance of the gas phase PE catalyst and the parameters of the multi-brand PE industrial production process. The device adopts the production process of continuous gas phase polymerization, and the design capacity is 5kg / hr. The main body of the device includes raw material and catalyst feeding system, gas phase reactor system, polymer separation system, back blowing gas system, etc.; it is equipped with raw material purification system, instrument air system, cooling water system, discharge system, etc., of which the instrument air system and cooling water system It is shared with the loop pipe pilot plant in the workshop, and the high-purity nitrogen, steam, circulating water, etc. used by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com