Brushless DC (Direct Current) motor with brushless AC (Alternating Current) composite excitation

A technology of brushed DC motor and compound excitation, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of high excitation loss, low power density, and reduced excitation efficiency, and achieve high excitation efficiency and wide excitation range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

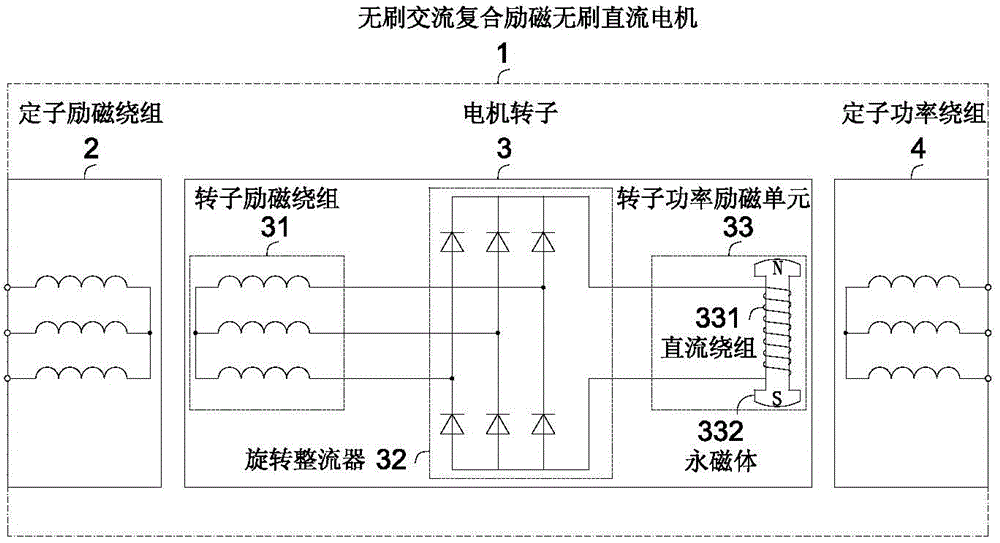

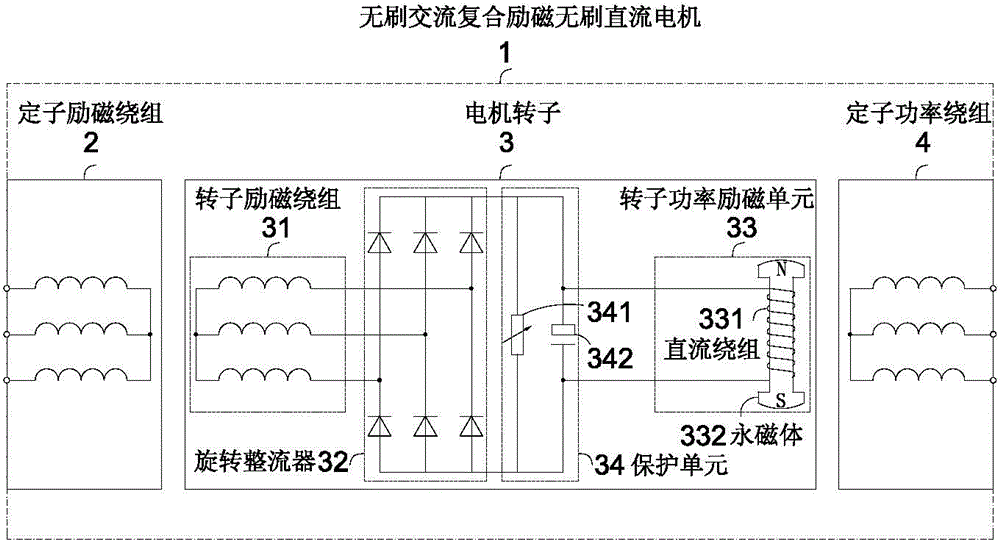

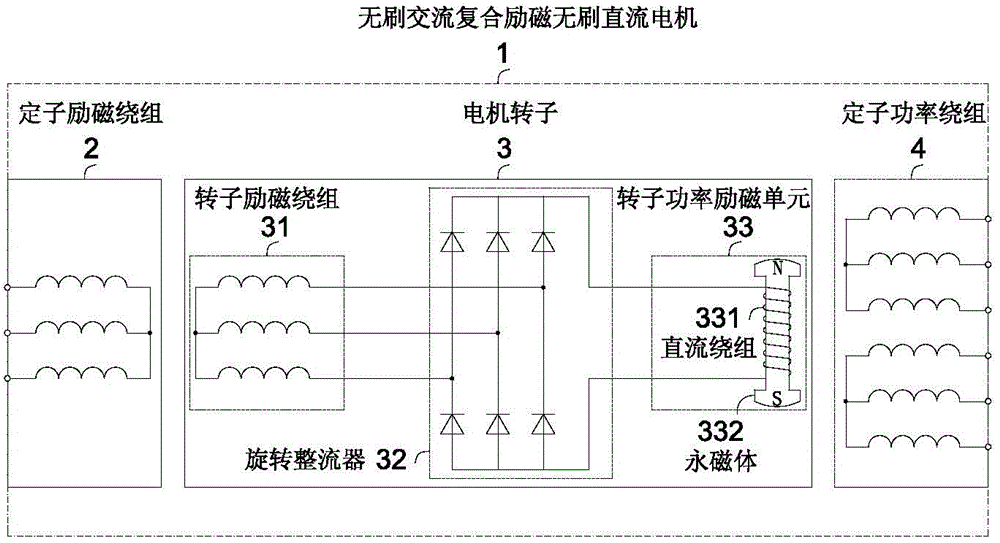

[0045]This brushless AC composite excitation brushless DC motor 1 includes a stator excitation winding 2, a motor rotor 3, and a stator power winding 4. The motor rotor 3 includes a rotor excitation winding 31, a rotating rectifier 32, and a rotor power excitation unit 33. , the rotor power excitation unit 33 includes a DC winding 331 and a permanent magnet 332, the DC winding 331 is attached to the permanent magnet 332 and the two perform composite excitation.

[0046] Furthermore, the stator field winding 2 adopts AC frequency conversion excitation, and generates an AC frequency conversion induced electromagnetic field by inputting frequency conversion alternating current in the stator field winding 2, so that the rotor field winding 31 in the motor rotor 3 generates alternating current, which is rectified by the rotating rectifier 32 It is direct current, and the direct current provides current for the direct current winding 331 in the rotor power excitation unit 33 to gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com