Micro-fluidic chip and self-assembling method

A microfluidic chip and self-assembly technology, applied in the field of microfluidics, can solve the problems of consuming a large dispersed phase, consuming a long time, difficult to control particle dispersion and size, and achieving uniform particle morphology, easy manipulation, Easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

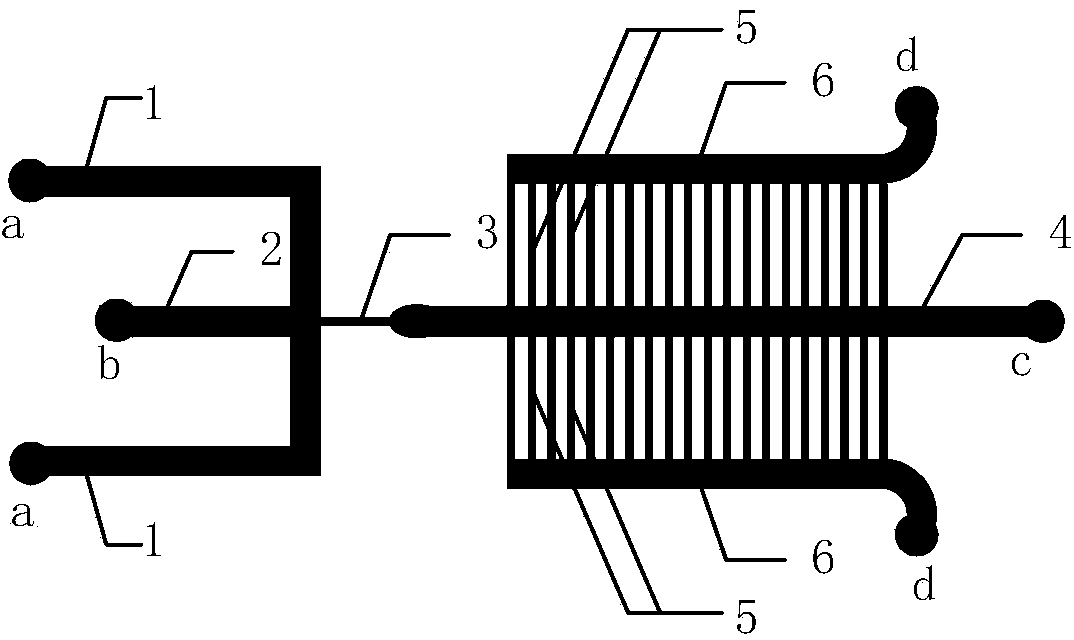

[0025] refer to figure 1 , a structural schematic diagram of a microfluidic chip in a preferred embodiment of the present invention, the liquid enters the first channel 1 and the second channel 2 respectively and then merges into the third channel 3, flows through the third channel and then enters the fourth channel 4 and connects with the fourth channel Several branch channels 5 communicated by the channel, the chip also includes side channels 6 communicated with the branch channels, the width of the third channel 3 is less than the width of the first channel 1, the second channel 2 and the fourth channel 4, the first channel 1 The second channel 2 is axisymmetrically distributed, the branch channel 5 and the side channel 6 are distributed axisymmetrically with the fourth channel 4, and the branch channel 5 is vertically connected to the fourth channel 4, the first channel 1 and the second channel 2 There are liquid inlets a and b respectively, and the fourth channel 4 and th...

Embodiment A

[0037] Phase A is hexadecane, in which 2.5wt% Span80 is added as a surfactant, and phase B is deionized water. Using a fluid pump, the two phases A and B are introduced into the first channel 1 and the second channel through the liquid inlets a and b respectively. In the second channel 2, when the flow rate of phase A is 40-100 μL / h, and the flow rate of phase B is 15-50 μL / h, the size of micro-droplets of phase B is 30-48 μm, which is a one-dimensional close-packed structure formed by self-assembly. When the flow rate of phase A is 100-400 μL / h, and the flow rate of phase B is 50-100 μL / h, the size of micro-droplets of phase B is 25-30 μm, and a two-dimensional close-packed structure is formed by self-assembly.

[0038] When the flow rate of phase A is 400-600 μL / h, and the flow rate of phase B is 100-200 μL / h, the size of micro-droplets of phase B is 20-30 μm, which is a three-dimensional close-packed structure formed by self-assembly.

Embodiment B

[0040] Phase A is hexadecane, add 2.5wt% Span80 as a surfactant, phase B is 6wt% N-isopropylacrylamide aqueous solution, and use a fluid pump to introduce the two phases A and B through the liquid inlets a and b respectively In the first channel 1 and the second channel 2, adjust the flow rate of phase A to 900-1200 μL / h, and the flow rate of phase B to 400-600 μL / h. The obtained micro-droplets of phase B have a size of 18-30 μm. stacked structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com