An autotrophic denitrification granular sludge reactor with automatic floating mud crushing cycle

An autotrophic denitrification granule and sludge reactor technology, which is applied in water/sludge/sewage treatment, chemical instruments and methods, biological water/sewage treatment, etc. It is difficult to collect and other problems to achieve the effect of ensuring denitrification performance, efficient denitrification performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

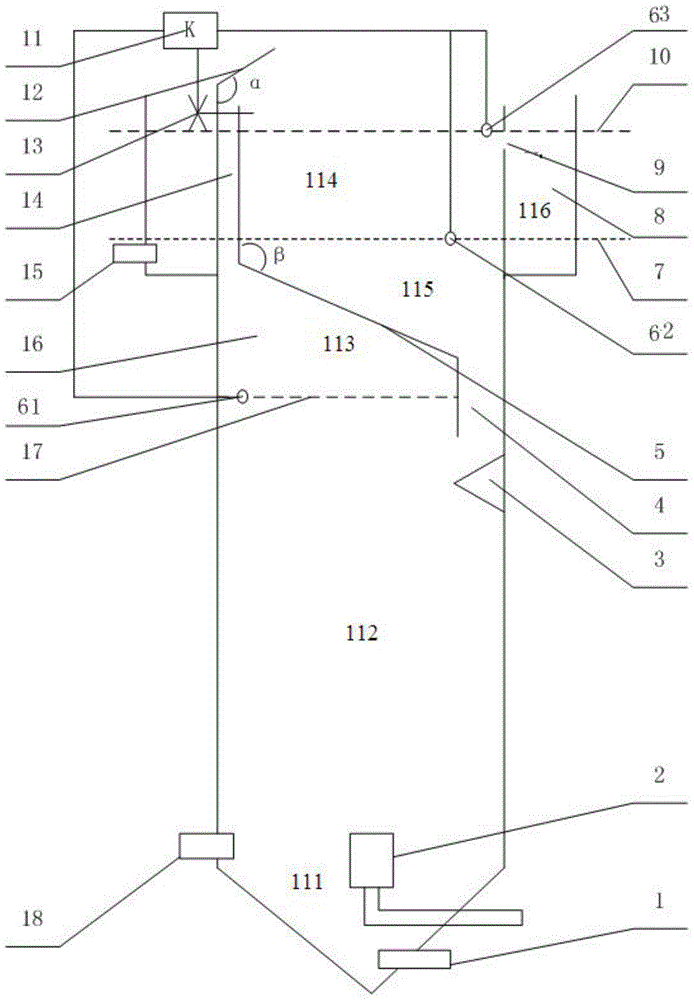

[0020] Further illustrate the present invention below in conjunction with accompanying drawing

[0021] Referring to the attached picture:

[0022] An autotrophic denitrification granular sludge reactor with automatic floating mud crushing cycle according to the present invention is characterized in that it includes a reactor body and an external control device, and the reactor body is equipped with a drain from bottom to top. Mud water distribution unit 111, reaction unit 112, floating mud crushing unit 113, crushed mud collection unit 114, crushed mud circulation unit 115, and water outlet unit 116. The mud discharge water distribution unit 111 is provided with a water inlet 1 and an aeration head 2 and mud outlet 18, the water inlet 1 and the mud outlet 18 are arranged at the bottom of the reactor body, and the air outlet of the aeration head 2 points to the inside of the reactor body; the floating The mud crushing unit 113 includes a gas collection chamber 16, an injectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com