Refining and chemical sewage desalting integrated treatment process and device

A technology for refining and chemical sewage and treatment process, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, general water supply saving, etc., can solve problems such as membrane pollution, achieve simple process, control membrane pollution, desalination high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

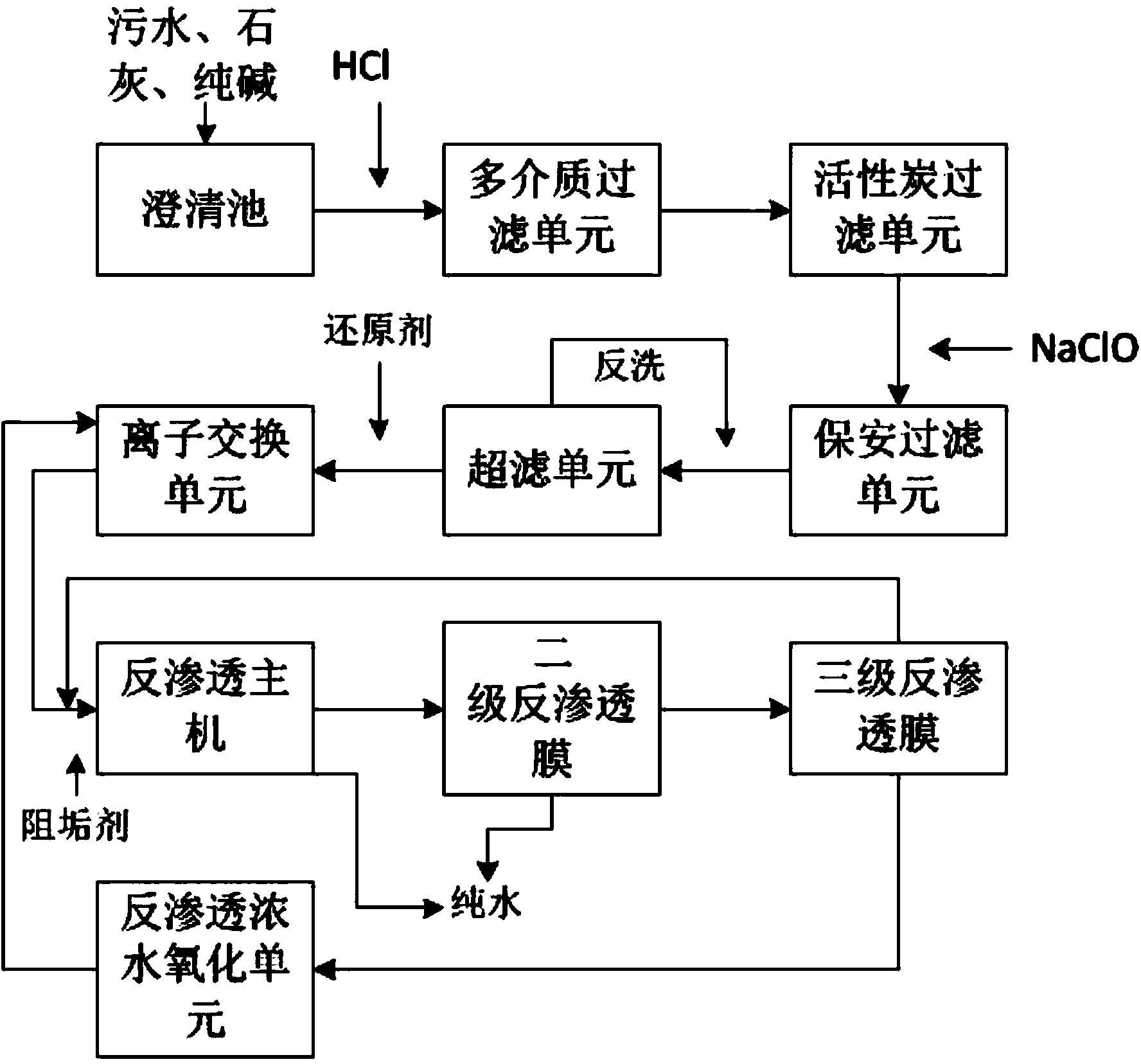

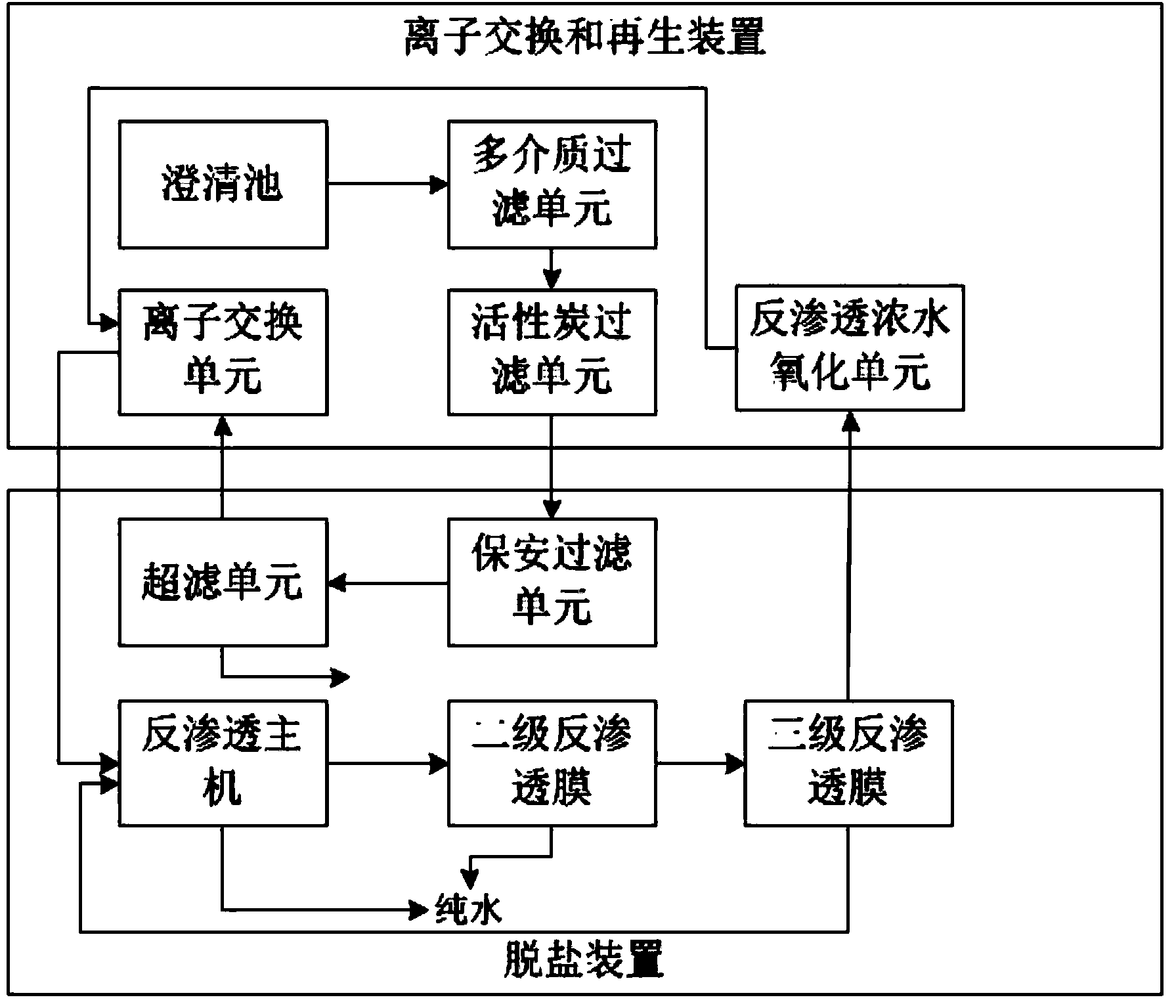

[0045] This example provides an integrated refinery sewage desalination treatment process, which is applied and studied in Lanzhou Petrochemical. The process is as follows figure 1 shown, including the following steps:

[0046] Step 1: Add CaO and Na to the primary treated refinery wastewater 2 o 3 Remove the hardness, settle in the clarifier, remove the sediment, adjust the pH with acid, and get the preliminary hardness-removed sewage;

[0047] Step 2, filtering the preliminary dehardened sewage in a multimedia filter unit, and then filtering in an activated carbon filter unit to obtain pretreated sewage;

[0048] Step 3: Mix the pretreated sewage and sodium hypochlorite, first pass through the security filter unit for prefiltration, and then perform ultrafiltration in the ultrafiltration unit, and the ultrafiltration treated sewage is backwashed by the backwash pump to the ultrafiltration membrane, and then Enter the ultrafiltration water tank for buffering, and then perf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com