ITO film and preparation method thereof

A thin film and substrate technology, which is applied in the field of ITO thin film and ITO thin film preparation, can solve the problem that the resistance uniformity of ITO glass is difficult to control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

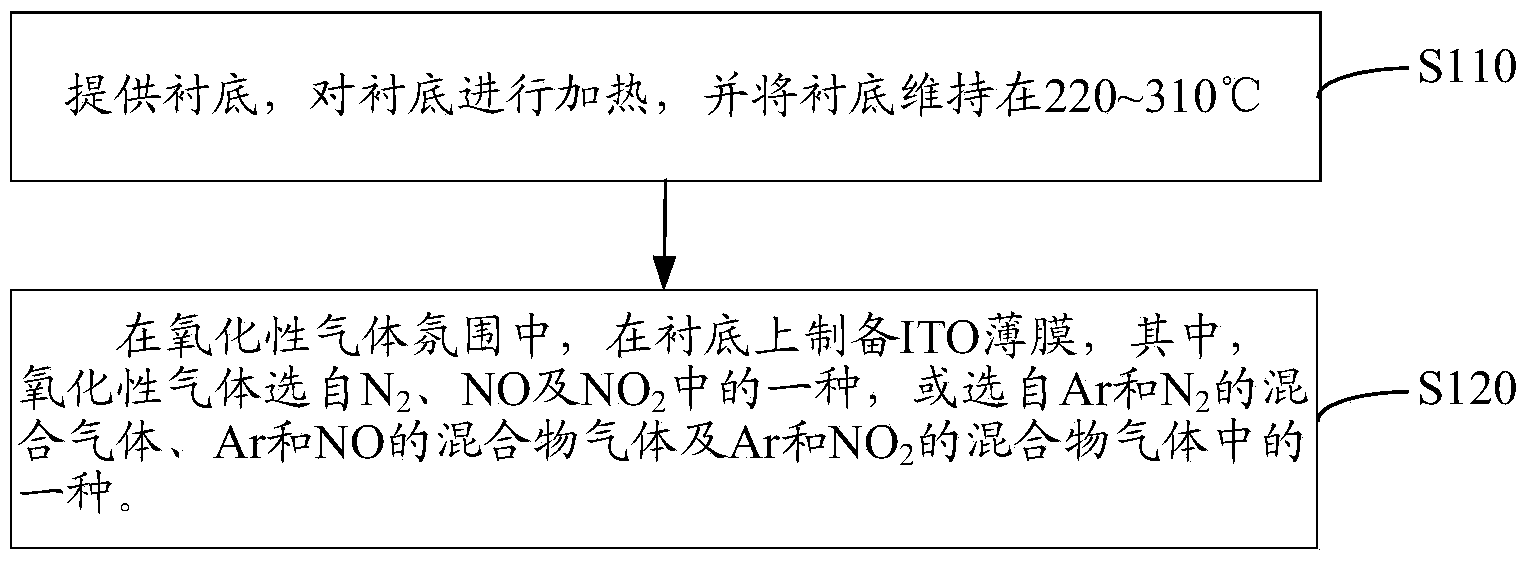

[0029] The above-mentioned preparation method of ITO film prepares ITO film in an oxidizing gas atmosphere at a suitable substrate temperature, so that the oxidizing gas is adsorbed into the ITO film and combined with In and Sn atoms to become a part of the ITO film crystal It reduces the number of carriers in the ITO film, reduces the gap resistance in the ITO film, prevents the ITO film from changing the film resistance and gap resistance due to the absorption of reducing gas, and avoids the problem of reducing the resistance of the ITO film , Thereby solving the traditional problem of poor uniformity of resistance caused by solving the problem of resistance reduction.

[0030] The preparation method of the above ITO film is simple in process, and there is no need to increase the original resistance requirement during preparation, and the quality of the ITO film can be better controlled.

[0031] The above-mentioned ITO film preparation method fundamentally solves the problem of ...

Embodiment 1

[0035] 1. Provide a 0.4mm thick glass substrate and clean the glass substrate, then load the glass into the coating line, and use the heater of the coating line to gradually heat the glass substrate to 220°C during the glass travel and maintain it at 220°C.

[0036] 2. Pass N when preparing ITO film 2 As an oxidizing gas, in an oxidizing gas atmosphere, magnetron sputtering is used to prepare an ITO film with a common transmittance and a surface resistance range of 350-500 for resistive touch screens on a glass substrate. Where N 2 The flow rate is 0.3sccm, Ar is used as the process gas, the flow rate of Ar is 120sccm, the voltage of magnetron sputtering is 350V, the power is 3.2kw, and the coating cycle is 50s.

[0037] The UV2450 spectrophotometer produced by Shimadzu was used to measure the light transmittance of the ITO film ≥90%.

[0038] The surface resistance of the prepared ITO film is measured by the SDY-5 four-probe instrument produced by Guangzhou Semiconductor to be 380-...

Embodiment 2

[0040] 1. Provide a 0.7mm glass substrate and clean the glass substrate, then load the glass into the coating line, and use the heater of the coating line to gradually heat the glass substrate to 270°C during the glass travel and maintain it at 270 ℃.

[0041] 2. Pass NO when preparing ITO film 2 As an oxidizing gas, in an oxidizing gas atmosphere, magnetron sputtering is used to prepare high-transmittance TP-400 ohm ITO glass for resistive touch screens with a transmittance of 93% and a resistance range of 400 to 600 ohms on a glass substrate . Among them, NO 2 The flow rate is 0.6sccm, Ar is used as the process gas, the flow rate of Ar is 120sccm, the voltage of magnetron sputtering is 312V, the power is 1.85kw, and the coating cycle is 150s.

[0042] The light transmittance of the ITO film was determined to be ≥93% using a UV2450 spectrophotometer produced by Shimadzu.

[0043] The surface resistance of the prepared ITO film measured by the SDY-5 four-probe instrument produced b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com