Fuel module used for spray gun, fuel cell device, thermal spraying device, thermal deburring device and fullerene manufacturing device

A technology of thermal spraying and equipment, applied in the field of similar spray gun equipment, can solve the problems of incompatibility, expensive, irreplaceable and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

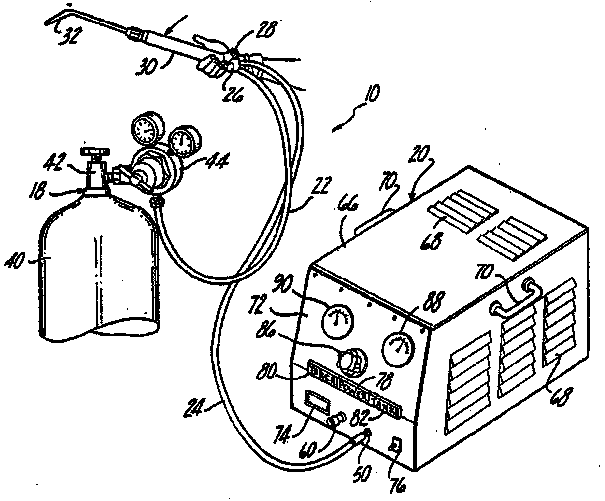

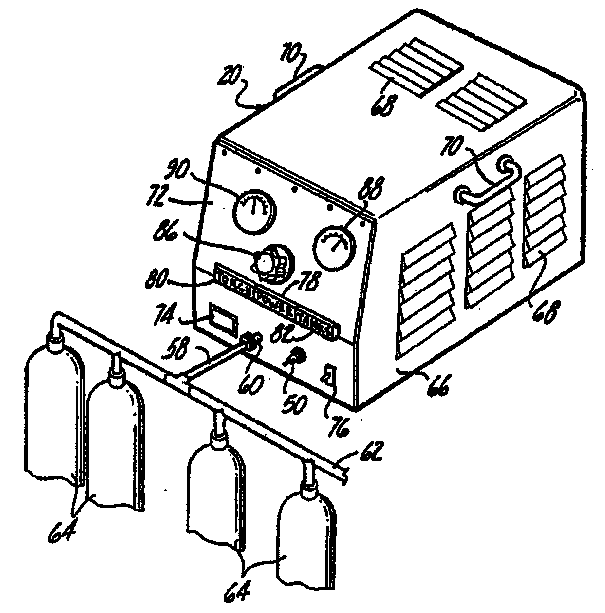

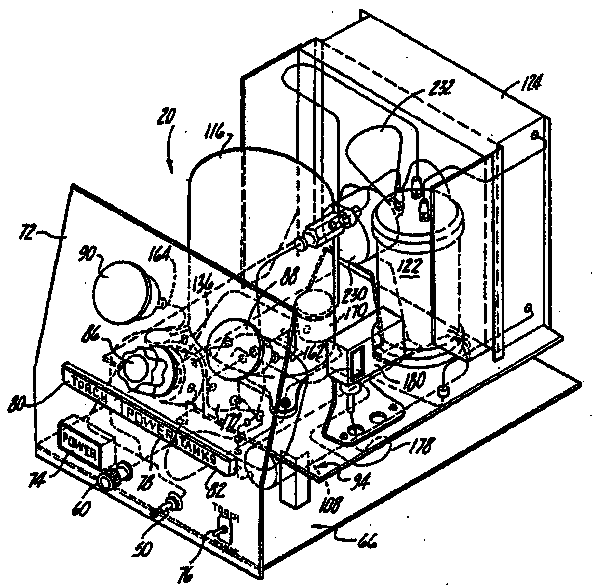

[0026] Figures 1 to 4 An exemplary embodiment of a gaseous fuel spray gun device according to the present invention is shown, comprising a gaseous fuel (such as natural gas) suitable for interval use when supplying a gaseous fuel (such as natural gas) to the spray gun device or for selectively storing one or more gaseous fuels. Exemplary fuel modules for refueling with containers or storage tanks. Those skilled in the art will readily appreciate from the following discussion and accompanying drawings that the principles of the present invention apply equally to spray gun devices and fuel modules, in addition to those shown in the drawings for illustrative purposes. It will also be apparent from the following discussion and accompanying drawings that the present invention is applicable to a wide variety of applications in addition to the gun-supplied and storage-container-supplied applications shown in the drawings for purposes of illustration .

[0027] Such as figure 1 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com