Low-thermal-resistance radiating LED lamp

An LED lamp and LED lamp bead technology, applied in the field of lighting, can solve the problems of small micro contact area, less thermal conductivity than aluminum radiator, affecting heat dissipation effect, etc., to reduce process time and labor needs, ensure life and brightness, and heat dissipation. obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below through specific examples, but not in order to limit the present invention, all within the spirit and principle of the present invention, any modification, equivalent replacement, improvement etc. all should be included within the scope of protection of the present invention .

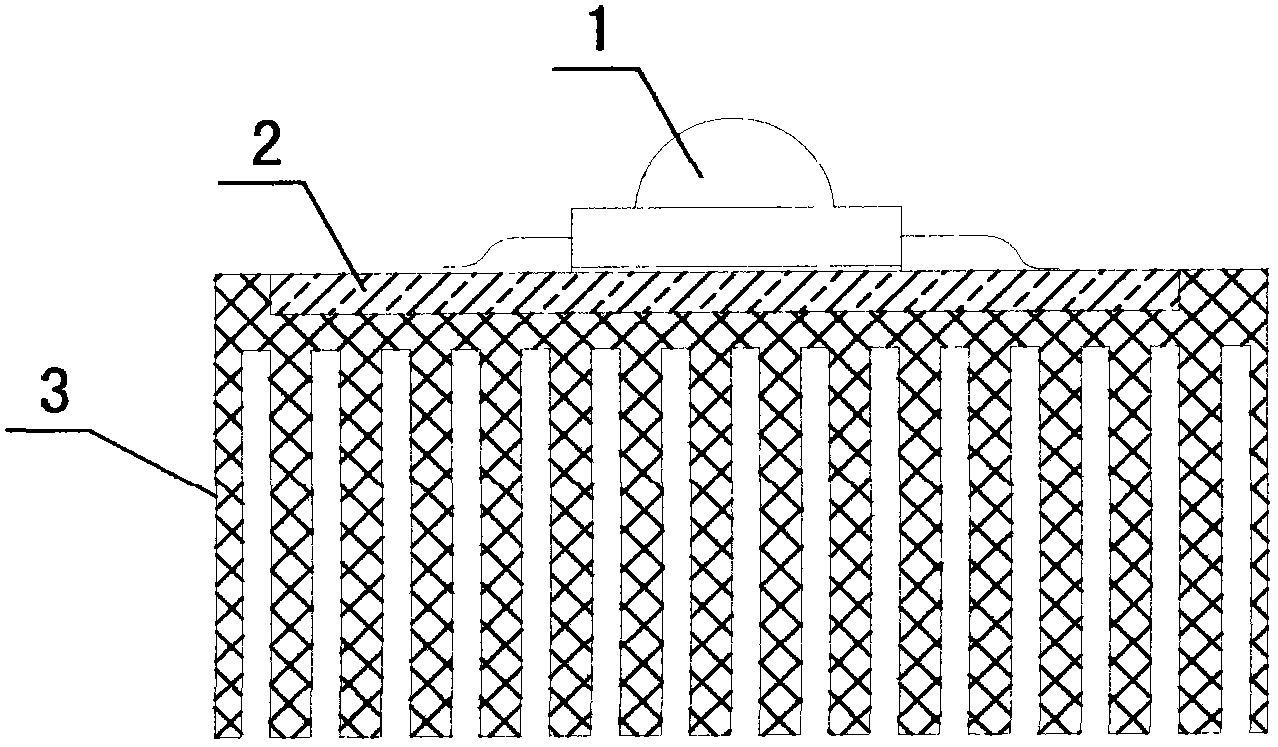

[0018] Such as figure 1 As shown, the low thermal resistance heat dissipation LED lamp includes a plastic heat sink 3 , LED lamp beads 1 and a ceramic substrate 2 , the LED lamp beads 1 are soldered on the upper surface of the ceramic substrate 2 , and the ceramic substrate 2 is embedded on the top of the plastic heat sink 3 .

[0019] In this embodiment, the upper surface of the ceramic substrate 2 and the upper surface of the plastic heat sink 3 are on the same plane; the plastic heat sink 3 is made of thermally conductive plastic.

[0020] In actual application, the upper surface of the ceramic substrate 2 can also be higher than the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com