Drawing force detector and test method thereof

A drawing force and detector technology, applied in force/torque/work measuring instruments, testing of mechanical parts, testing of machine/structural parts, etc. The effect of high motion accuracy, improving test accuracy and reducing deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

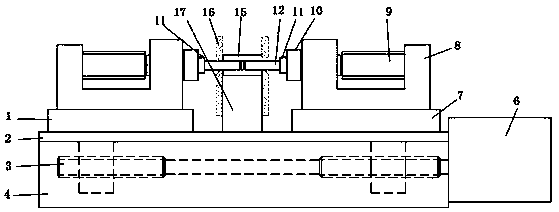

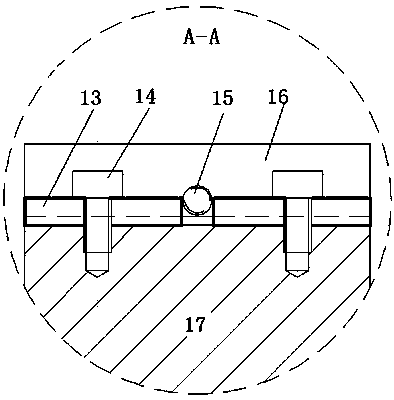

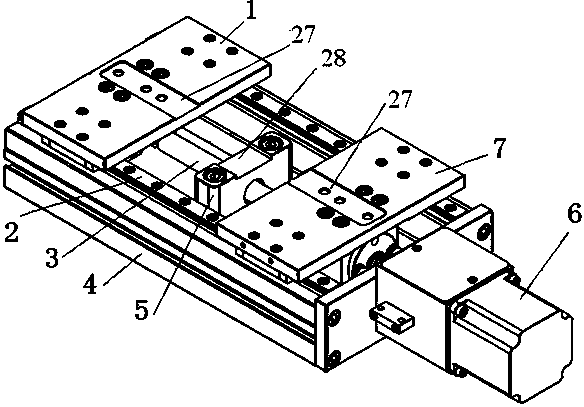

[0047] The pullout force detector in the present embodiment is as figure 1 As shown, it includes a base 4 and a slide rail 2 installed on the base 4 . A left slide 1 and a right slide 7 are installed on the slide rail 2, and a probe base 8 is respectively installed on the left slide 1 and the right slide 7, and the two probe bases 8 respectively clamped in the probe seat positioning grooves 27 on the left slide 1 and the right slide 7; each probe seat 8 is provided with a detection ferrule 12 and a clamping head 10 and the force sensor 9, wherein the detection ferrule 12 is fastened and fixed on one side of the clamping head 10 by a locking screw 11, and the other side of the clamping head 10 is connected with the force sensor 9, and at the same time The clamping head 10 is also floatingly connected with the probe base 8 ; the detection ferrules 12 on the two probe bases 8 are oppositely arranged. As a preferred implementation mode, the left sliding table 1 and the right sli...

Embodiment 2

[0056] On the basis of the pull-out force detector described in Embodiment 1, the pull-out force detector in the present embodiment is provided with a photoelectric switch on the stepper motor; in addition, the pull-out force in the present embodiment Detector is also provided with single-chip microcomputer system 20, and described single-chip microcomputer system 20 comprises:

[0057] Pulling force acquisition module 18 is connected with the force sensor 9, and the pulling force acquisition module 18 collects the voltage output signal of the force sensor 9 in real time through the A / D conversion channel, and converts it into pulling force data information;

[0058] Operational processing module 23, is connected with described pulling force acquisition module 18 and is arranged, receives the pulling force data information that described pulling force acquisition module 18 transmits and carries out arithmetic processing;

[0059] Digital I / O module 24, used for the input of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com