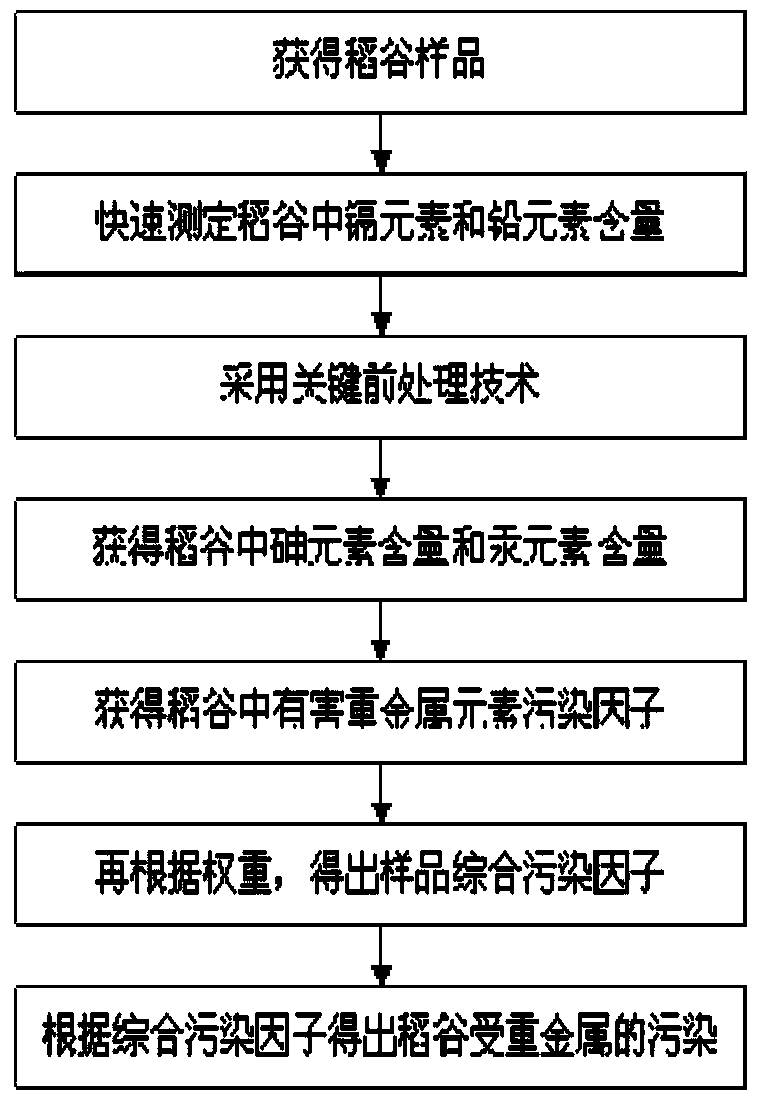

Methods for quickly detecting content of heavy metal elements in rice and evaluating comprehensive pollution index of heavy metal elements

A technology for element content and heavy metals, applied in measuring devices, color/spectral characteristic measurements, instruments, etc., can solve problems such as inability to fully reflect the degree of heavy metal pollution, and achieve the effect of avoiding cumbersome details and shortening the analysis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

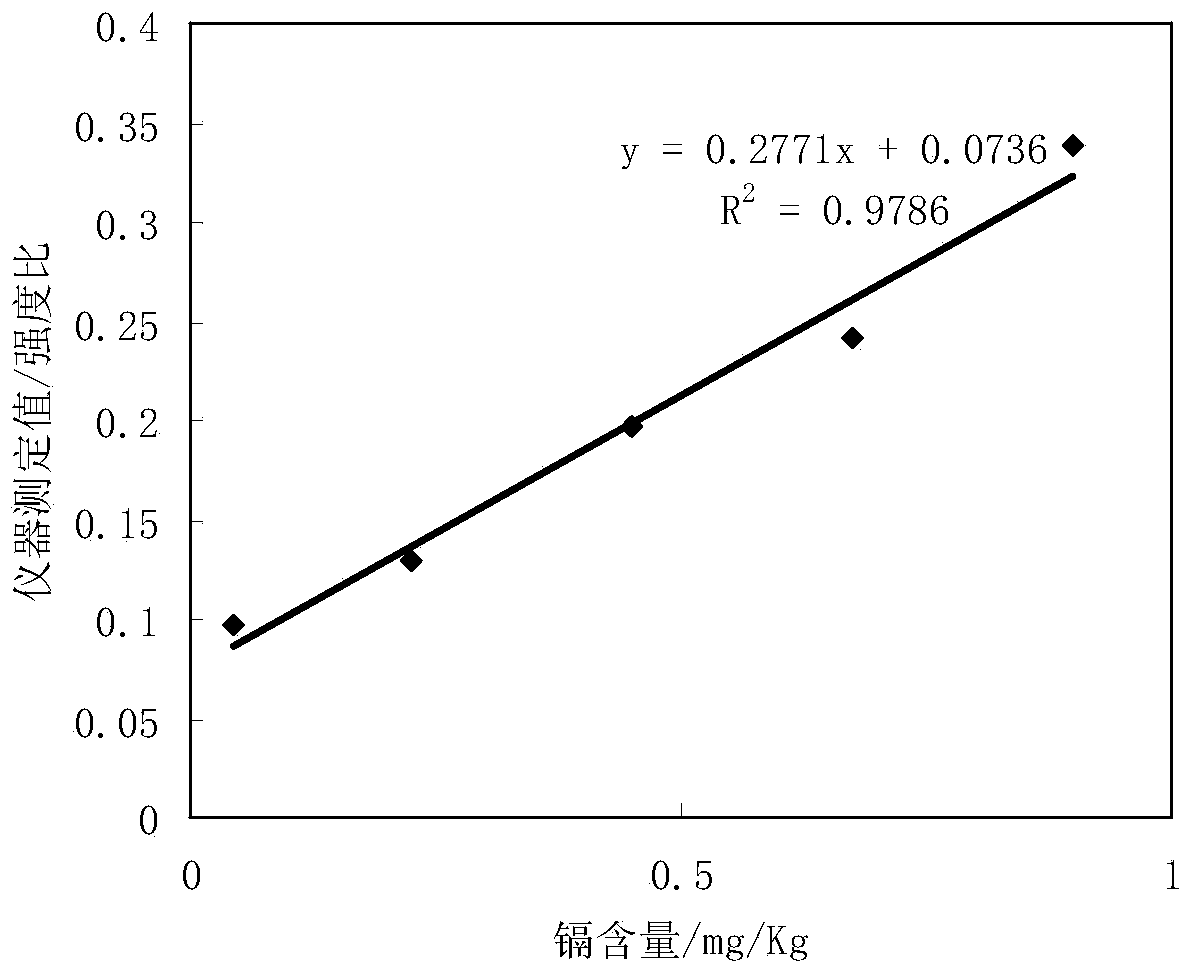

[0053] Example 1 Rapid Determination of Cadmium Element Content in Paddy

[0054] (1) Sample pretreatment

[0055]According to the grain and oil sample separation method, the grain samples are mixed evenly, and the 2Kg original sample is separated by a bell-shaped sample divider, and then the samples are divided step by step, and finally two parallel samples of each 50g are obtained. For processing, put the sample on a tray, pick out inorganic or organic impurities, take the clean rice and use a huller to hustle it into brown rice, and then use a cyclone mill without moisture loss to pulverize the brown rice, put it in a sealed bag, and mix it evenly. Obtain a sample of brown rice flour;

[0056] (2) Rapid determination of cadmium content in rice

[0057] Determination method: take the brown rice flour sample in step (1) and place it in a quartz tube for carbonization at 500°C to 600°C for 20min, take out the charcoal after cooling, weigh the mass of the charcoal, and calcul...

Embodiment 2

[0082] Example 2 Rapid Determination of Lead Element Content in Paddy

[0083] Sample pretreatment and assay method refer to embodiment 1;

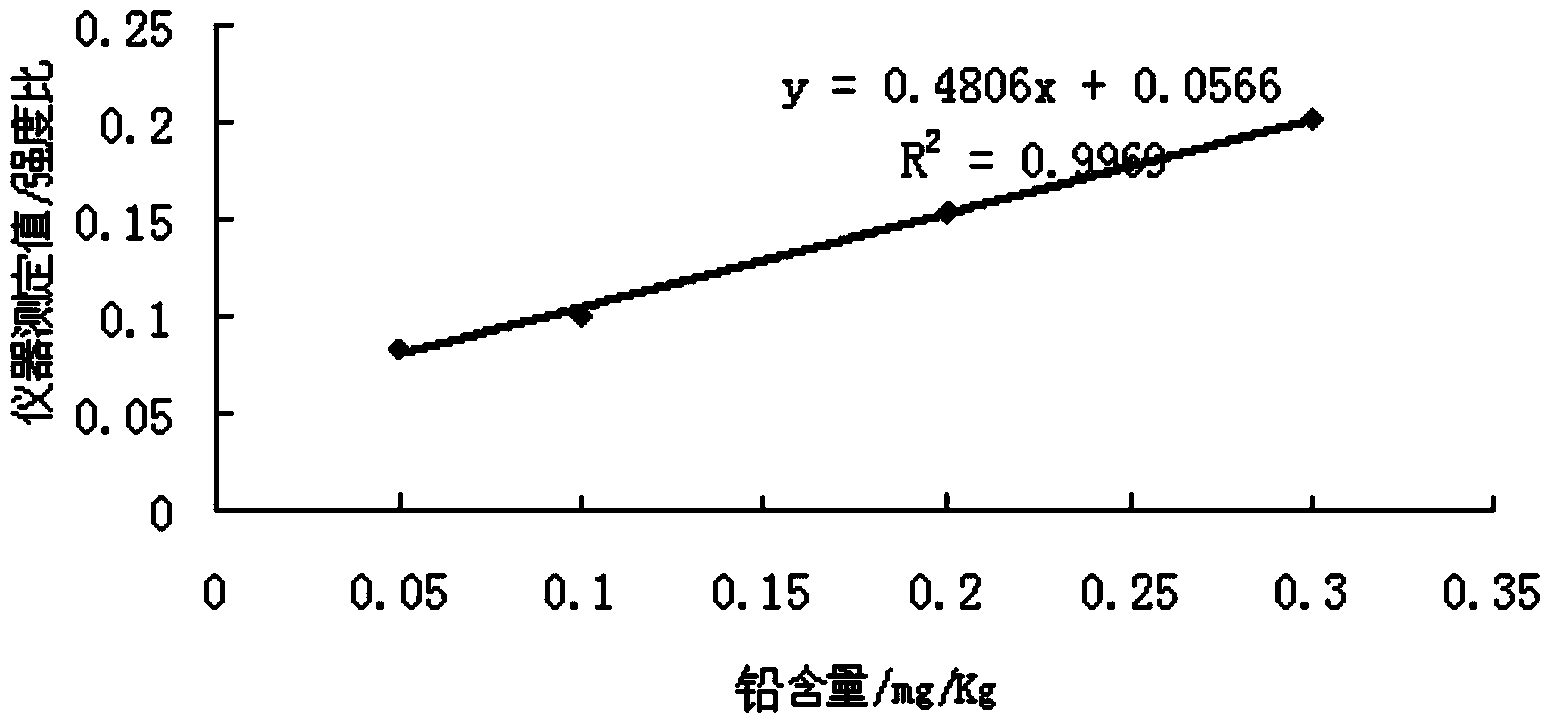

[0084] ① Correlation test

[0085] Weigh the brown rice flour sample of known heavy metal lead content value of 0.30mg / Kg (the sample with high content of lead in the rice is not easy to obtain, currently only has the known value sample of 0.3mg / Kg) and blank powder (theoretically does not contain lead element Ground rice), mix out the mixed powder that heavy metal lead content is 0.05 to 0.3mg / Kg, get 4 points, measure the strength ratio of mixed powder according to the assay method described in embodiment 1 step (2) (read out from instrument measurement result ), draw the correlation curve, see Table 7 and image 3 .

[0086] Table 7 Correlation test records of lead element content

[0087]

[0088] ②Accuracy test

[0089] Measure according to the assay method described in embodiment 1 step (2) " national standard material Sichu...

Embodiment 3

[0107] Example 3 Rapid determination of arsenic and mercury content in rice

[0108] ① Weighing of sample pretreatment

[0109] Prepare "National Standard Material Hunan Rice" (GBW10045 (GSB-23)) brown rice flour sample according to embodiment 1; Get the brown rice flour sample of 0.5g and place in a tall shape small beaker, and add 10mL superior grade pure concentrated nitric acid and 4 Drop analytically pure perchloric acid, cover with a concave glass slide, digest by wet method, and react for 3h ( Figure 4 );

[0110] ② Digestion of sample pretreatment ( Figure 5 )

[0111] Move the beaker to an anti-corrosion electric heating plate for heating and digestion, keep the temperature at 100°C for half an hour, let it smoke slowly; then raise the temperature to 220°C and keep it for 2 hours; when the volume of the digestive solution is about 0.3mL, white smoke will come out, Continue to heat for 4min, then add 1mL deionized water to drive away the acid, continue to evapora...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Injection volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com