Thin film material Seebeck coefficient measuring instrument

A Seebeck coefficient and thin-film material technology, applied in the direction of material thermal development, can solve problems such as inability to test thin-film materials, and achieve the effect of increasing data reliability and test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

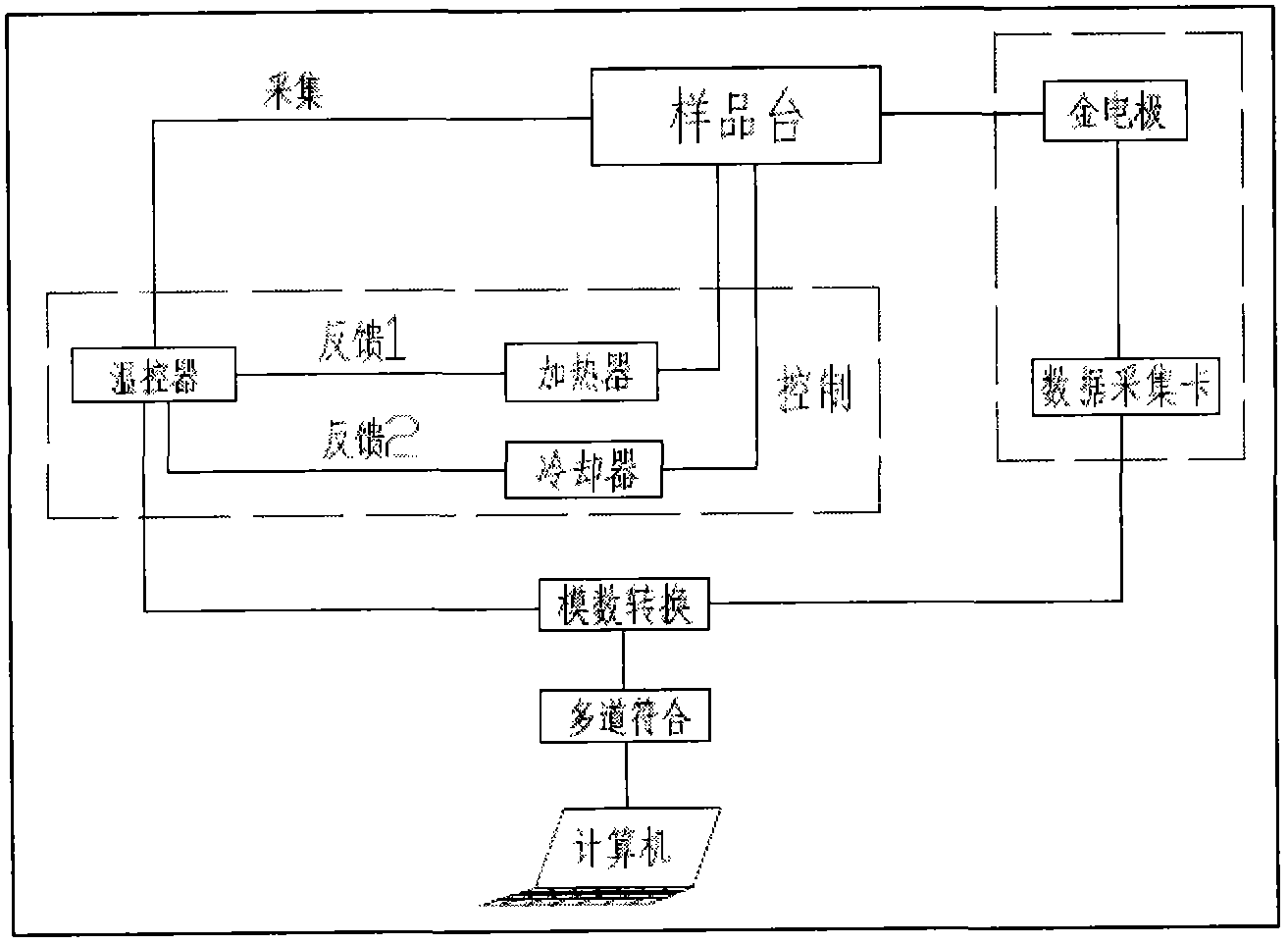

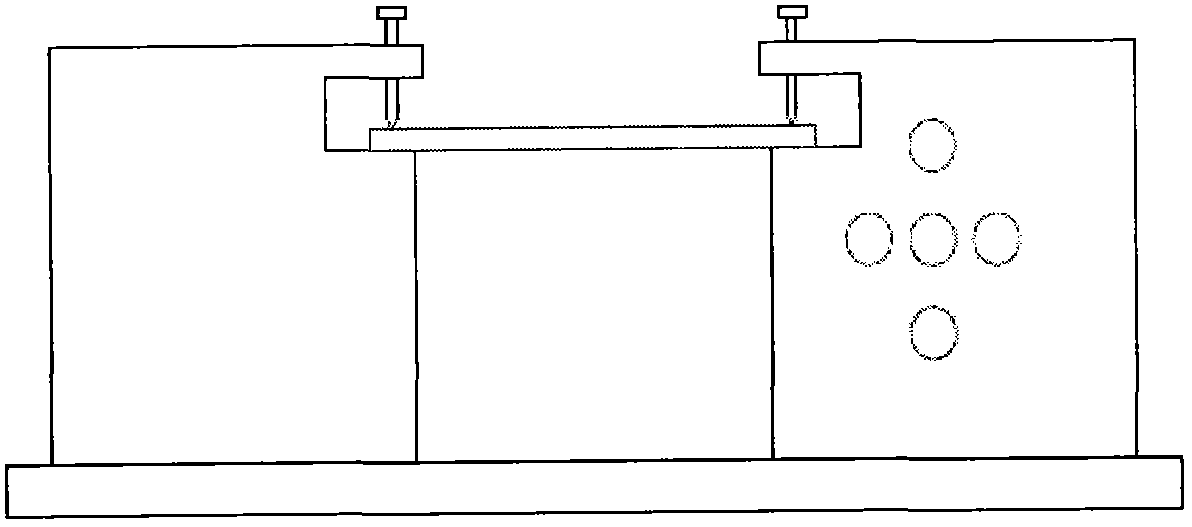

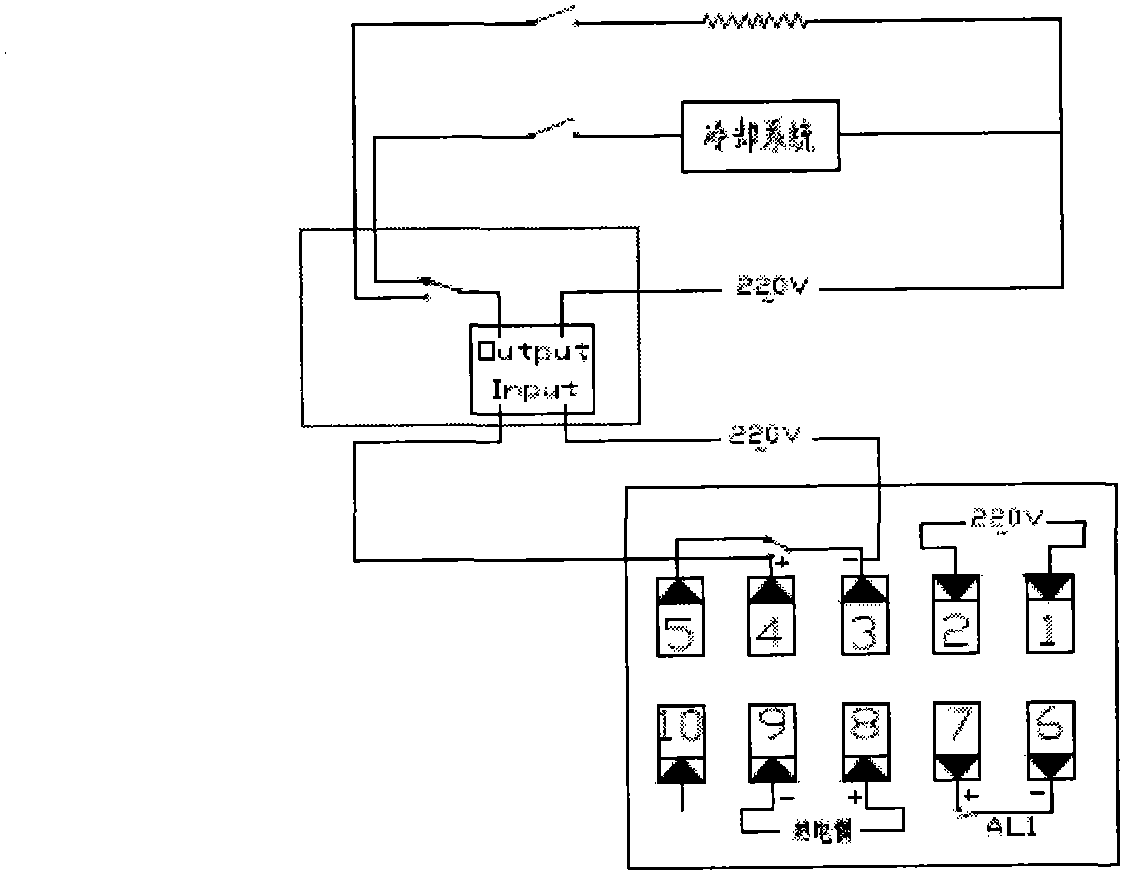

[0031] like figure 1 , figure 2 and image 3 As shown, the thin film material Seebeck coefficient measuring instrument provided in this embodiment includes a sample stage, a temperature control system and a data acquisition system. The sample stage includes a sample holder and a base, and the sample holder is divided into two parts for fixing the test samples, called hot and cold ends, respectively. The temperature control system includes a sensor, a temperature controller, a relay, a heater and a cooler, and the sensor, the heater and the cooler are all arranged on the sample holder, and the temperature controller collects the sensor signal through the The relay cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com