Calculation method of rapid heat conduction coefficient of period-like distribution unidirectional fiber toughening composite material

A toughened composite material and thermal conductivity calculation technology, applied in the field of engineering thermophysics, can solve the problems of many parameters required for calculation, long time consumption, limited accuracy of thermal conductivity calculation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

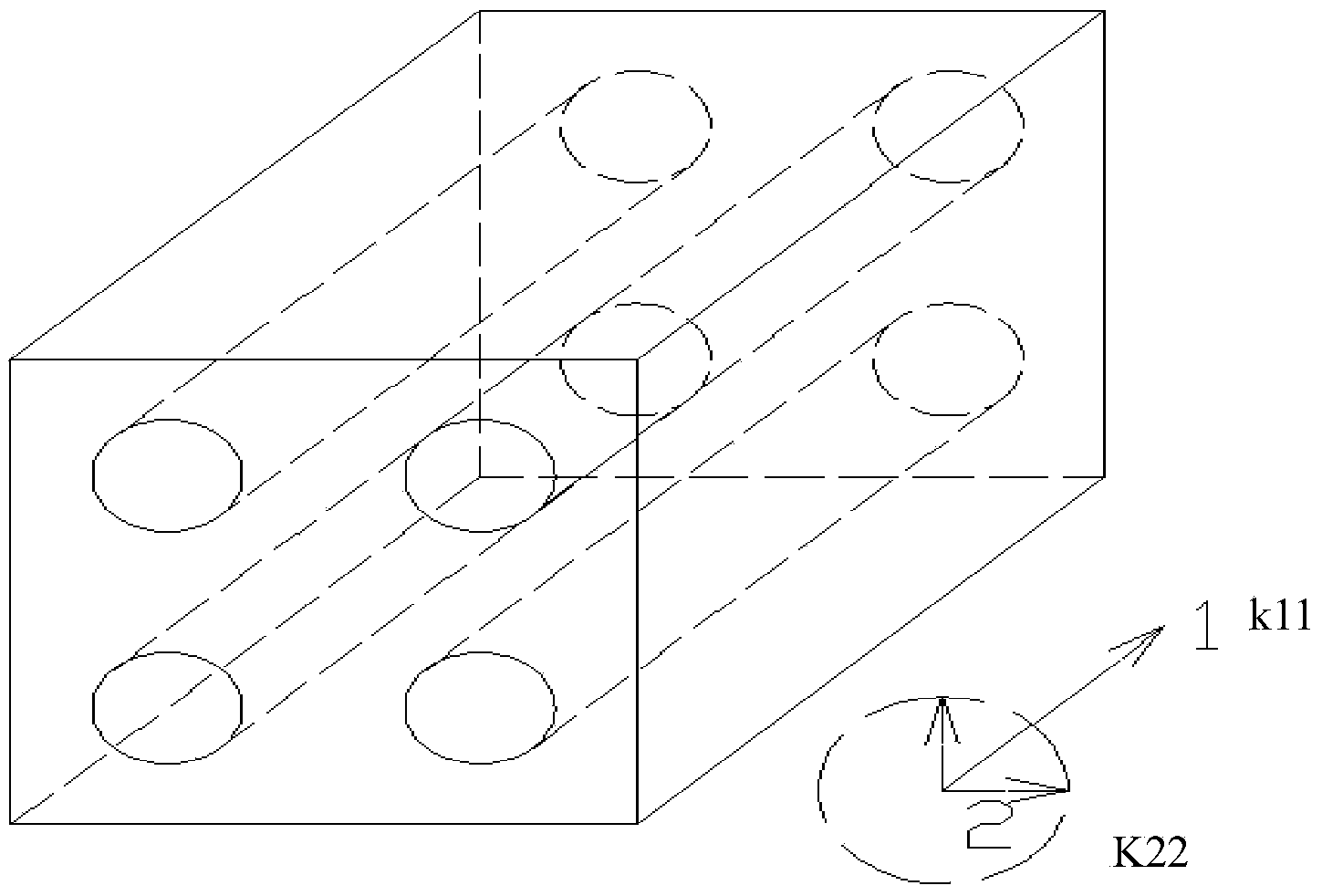

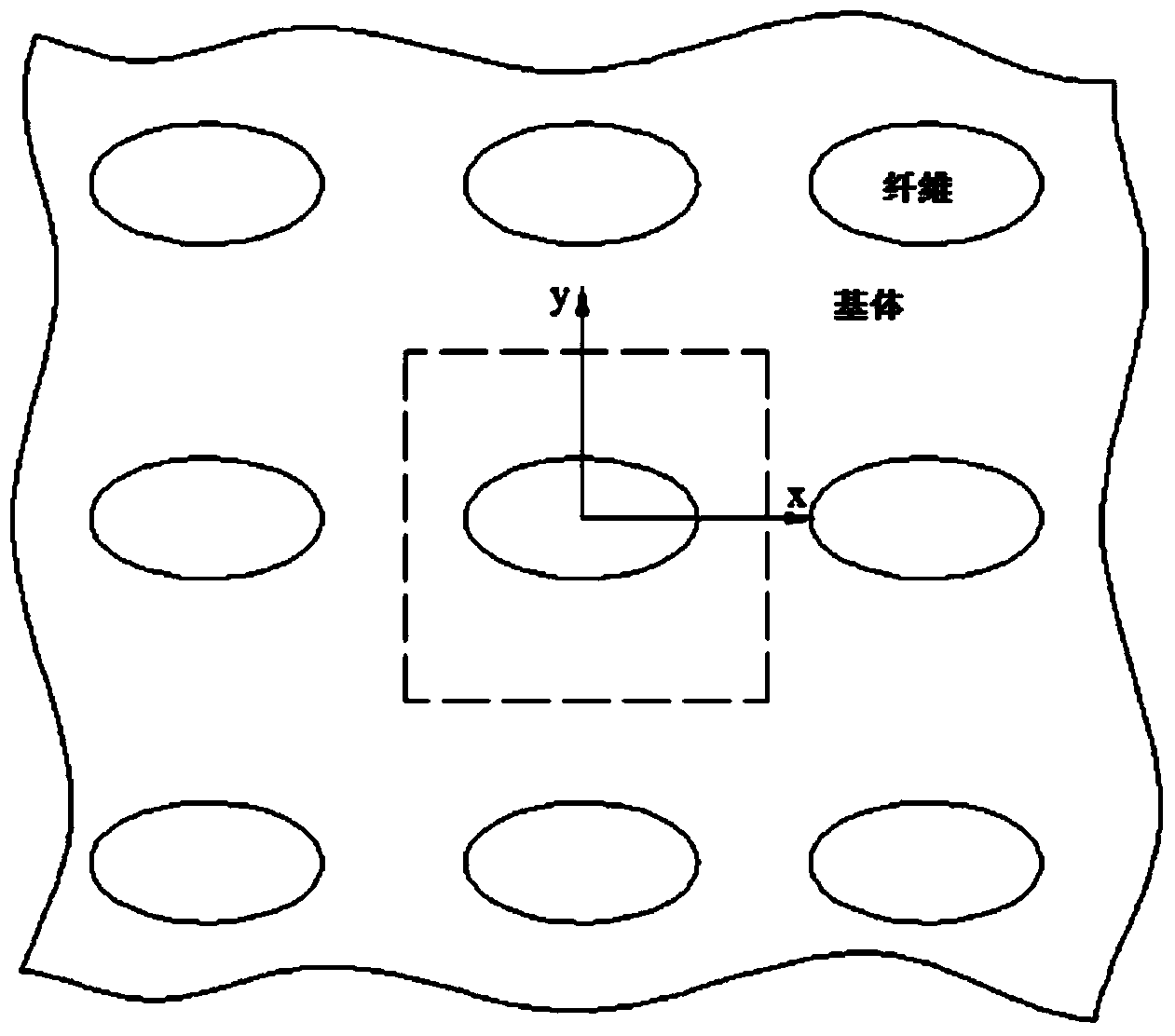

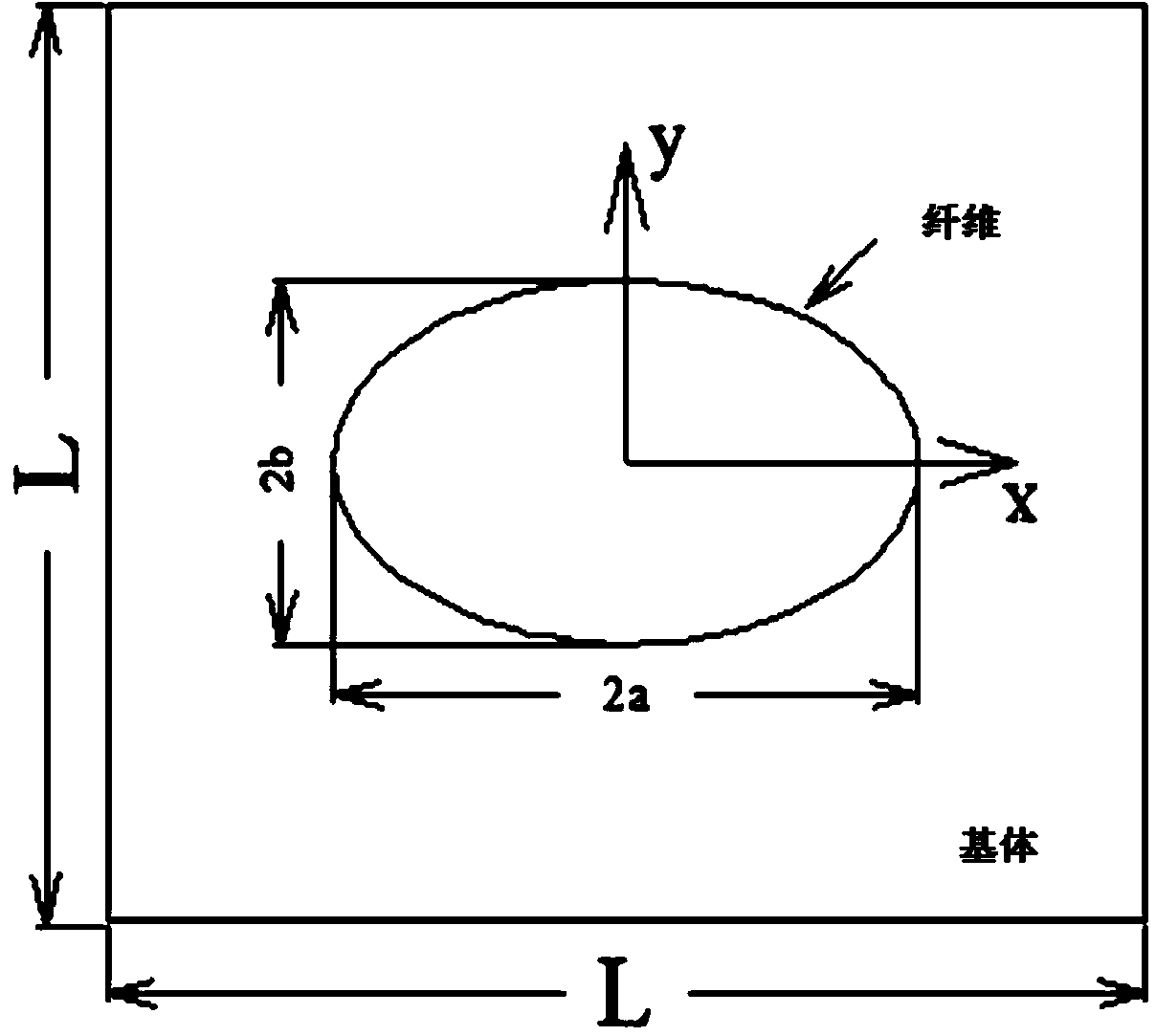

[0052] Please refer to figure 1 As shown, according to the arrangement characteristics of unidirectional fibers in composite materials, and for the sake of simplicity of calculation, appropriate simplification is made here, and the specific assumptions are as follows:

[0053] (1) The unidirectional fibers are arranged parallel to each other in the composite material matrix, and are arranged in a square in the transverse structure, which has periodic characteristics;

[0054] (2) The unidirectional fiber is closely connected with the matrix of the composite material, and there is no contact thermal resistance;

[0055] (3) The shape of the unidirectional fiber is oval.

[0056] After assumptions, the simplified unidirectional fiber toughened composite material calculation model is as follows figure 1 shown. It can be analyzed from the structure that unidirectional fiber toughened composite materials mainly include thermal conductivity in two directions: thermal conductivity k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com