A Method of Realizing Variable Free Illumination Pupil Based on Micromirror Array

A technology of micro-mirror array and micro-mirror, which is applied in the field of micro-lithography, and can solve the problems affecting the uniformity of light spots and the quality of reticle lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

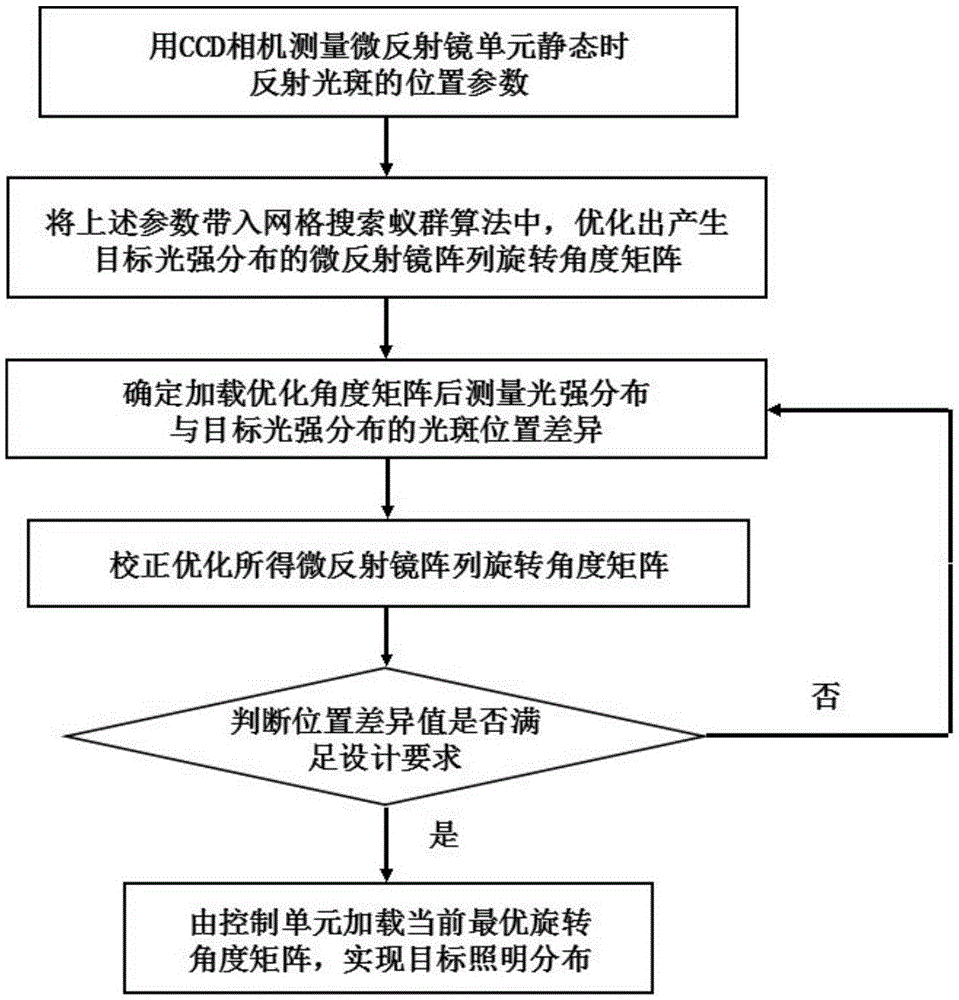

[0074] figure 1 It is a flow chart of the method for realizing a continuously variable free illumination pupil based on a micromirror array of the present invention, including three processes of spot position measurement, spot position optimization, and spot position correction. The specific steps are as follows:

[0075] Step (1), measure the position parameter of the reflected light spot on the illumination target surface when each micro-mirror unit is static with a CCD camera;

[0076] Step (2), bringing the position parameters of the reflected light spot measured in step (1) into the grid search ant colony algorithm, and optimizing the rotation angle matrix of the micromirror array that produces the required light intensity distribution;

[0077] Step (3), utilize the rotation angle matrix that step (2) obtains, generate the control signal of each micromirror to control its angle rotation, measure the light intensity distribution on the illumination target surface at this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com