Medicated leaven capsule for stomachache and preparation method thereof

A stomachache and capsule technology, applied in the field of Shenqu Weitong capsule and its preparation, can solve the problems of unsatisfactory curative effect, slow dissolution, low curative effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Take 100g of Clematis clematis, 280g of rhubarb, 100g of belladonna slices, 10g of ginger, grind them into 60-mesh coarse powder, and extract them with carbon dioxide supercritical extraction method, the extraction pressure is 30Mpa, the extraction temperature is 30°C, the separator pressure is 10Mpa, and the separator temperature is 50°C. ℃, the separation time is 2 hours, and the flow rate of carbon dioxide is 40L per hour to obtain the extract; take the extract and dry it under reduced pressure at 60°C to obtain a dry paste; add 150g of calcium sulfate to the dry paste, and use a high-energy nano-impact mill to pulverize it into a particle size of 200-300nm Mixed dry paste powder; take mixed dry paste powder, aspartame 45g, cross-linked polyvinylpyrrolidone 45g, mix well, wet granulate with 50% ethanol, dry at 60°C, add sodium carboxymethyl starch 7g, stearin Magnesium acid 1g, whole grain, packed into capsules, made into 1000 capsules.

specific Embodiment 2

[0023] Take 100g of Clematis clematis, 280g of rhubarb, 100g of belladonna slices, 10g of ginger, grind them into 60-mesh coarse powder, and use carbon dioxide supercritical extraction method to extract, the extraction pressure is 40Mpa, the extraction temperature is 40°C, the separator pressure is 20Mpa, and the separator temperature is 60 ℃, the separation time is 4 hours, and the carbon dioxide flow rate is 50L per hour to obtain the extract; take the extract and dry it under reduced pressure at 80°C to obtain a dry paste; add 200g of calcium sulfate to the dry paste, and use a high-energy nano-impact mill to pulverize it into a particle size of 200-300nm Mixed dry paste powder; take mixed dry paste powder, aspartame 55g, cross-linked polyvinylpyrrolidone 55g, mix well, wet granulate with 70% ethanol, dry at 80°C, add sodium carboxymethyl starch 9g, stearin Magnesium acid 3g, whole grain, packed into capsules, made into 1000 capsules.

Embodiment 3

[0025] Take 100g of clematis, 280g of rhubarb, 100g of belladonna slices, 10g of ginger, grind them into 60-mesh coarse powder, and extract them with carbon dioxide supercritical extraction method, the extraction pressure is 35Mpa, the extraction temperature is 35°C, the separator pressure is 15Mpa, and the separator temperature is 55°C. ℃, the separation time is 3 hours, and the flow rate of carbon dioxide is 45L per hour to obtain the extract; take the extract and dry it under reduced pressure at 70°C to obtain a dry paste; add 175g of calcium sulfate to the dry paste, and use a high-energy nano-impact mill to pulverize it into a particle size of 200-300nm Mixed dry paste powder; take mixed dry paste powder, aspartame 50g, cross-linked polyvinylpyrrolidone 50g, mix well, wet granulate with 60% ethanol, dry at 70°C, add sodium carboxymethyl starch 8g, stearin Magnesium acid 2g, whole grain, packed into capsules, made into 1000 capsules.

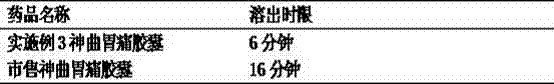

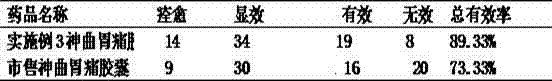

[0026] The above examples illustrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com