Intelligent vacuum logistics pipeline conveying system

A technology of pipeline transportation and vacuum pipeline, which is applied in the field of intelligent pipeline transportation system, can solve problems such as regular pipeline and vehicle maintenance, affecting normal cargo transportation, and no detection station, etc., to achieve convenient maintenance, lower resistance, and reduced emissions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

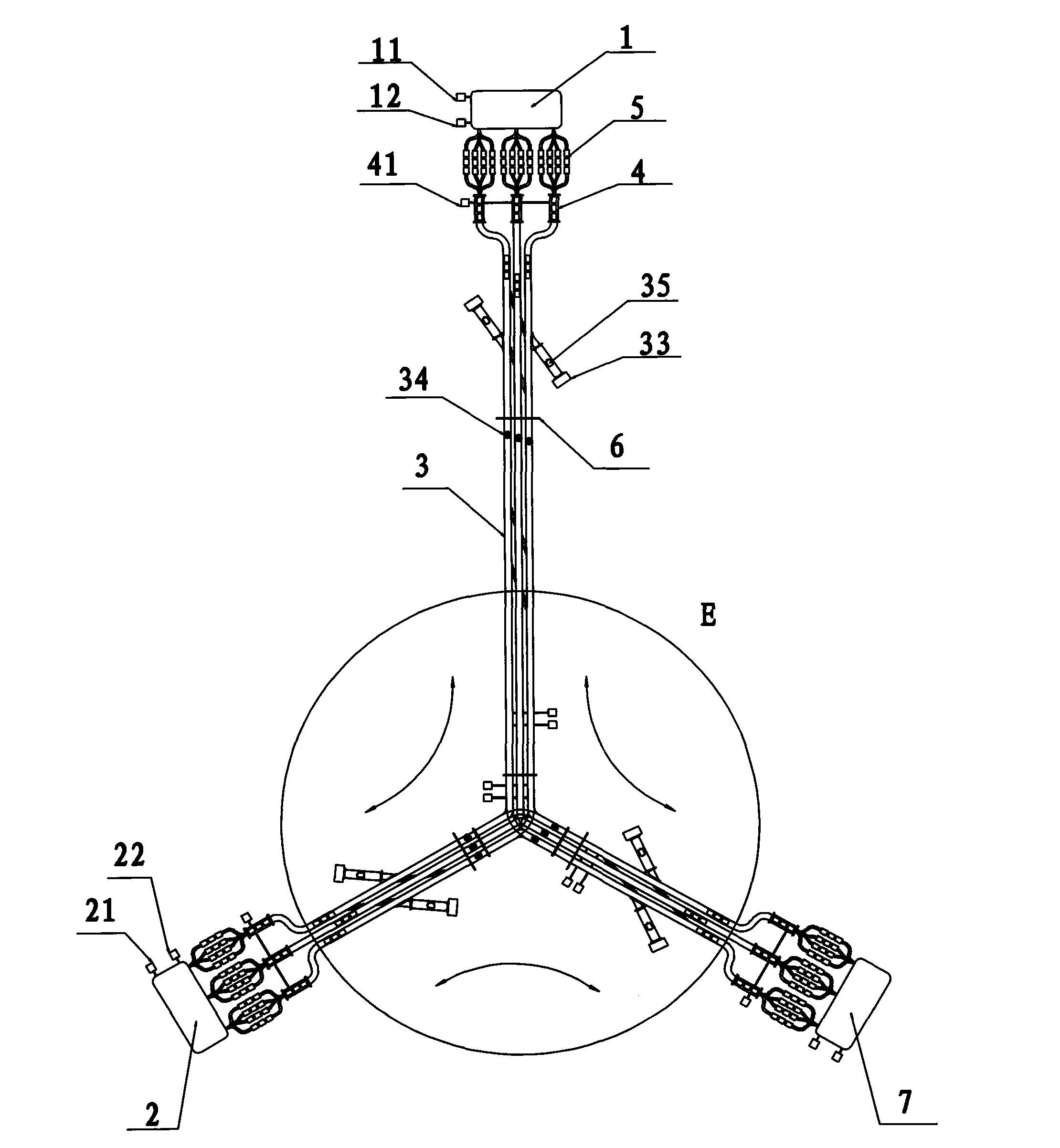

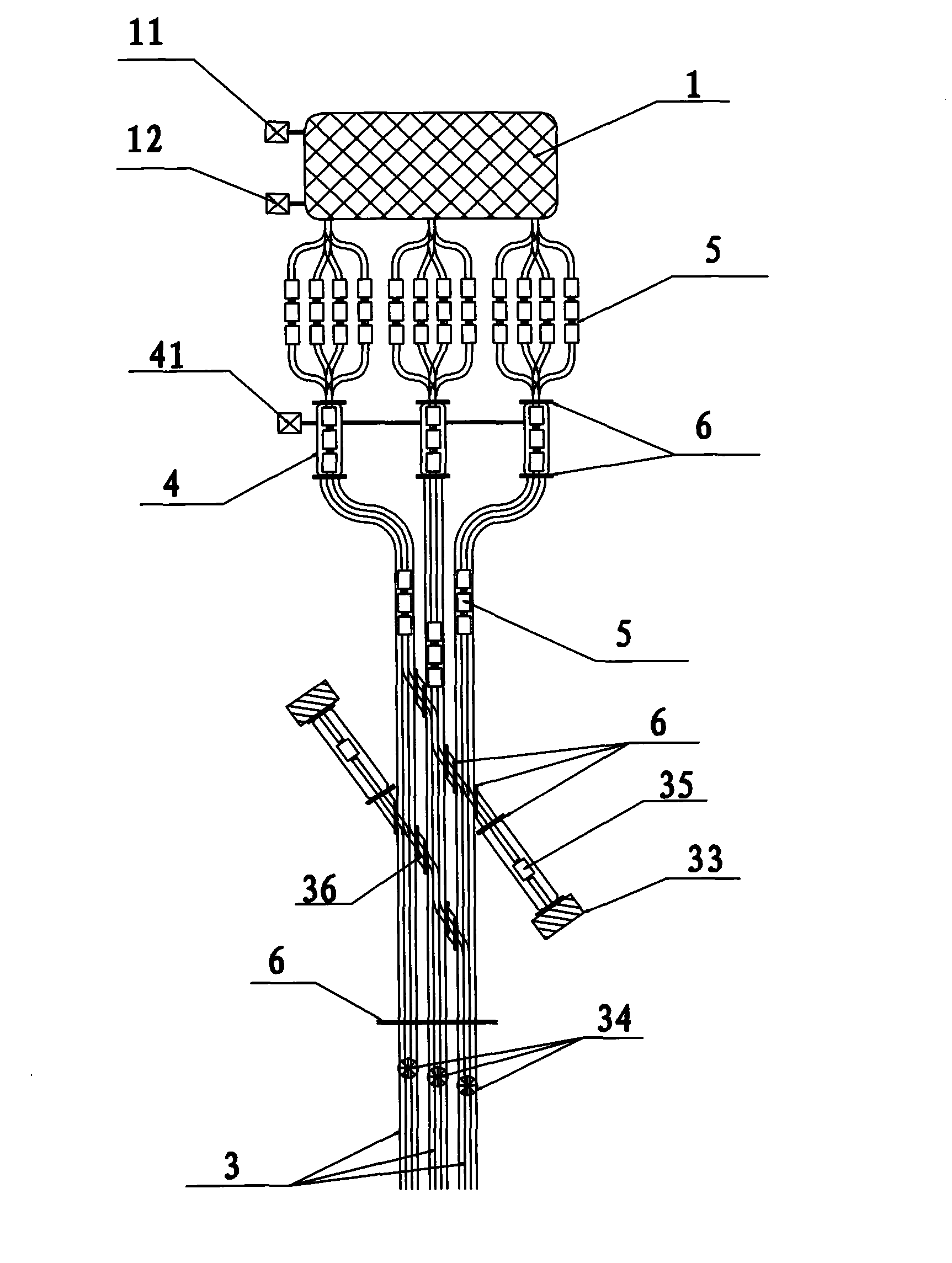

[0018] The invention provides an intelligent vacuum logistics pipeline transportation system, such as figure 1 With the structure shown, the pipeline transportation system adopts vacuum state transportation, which has high transportation efficiency, can be intelligently dispatched and controlled, saves manpower, and is convenient for maintenance.

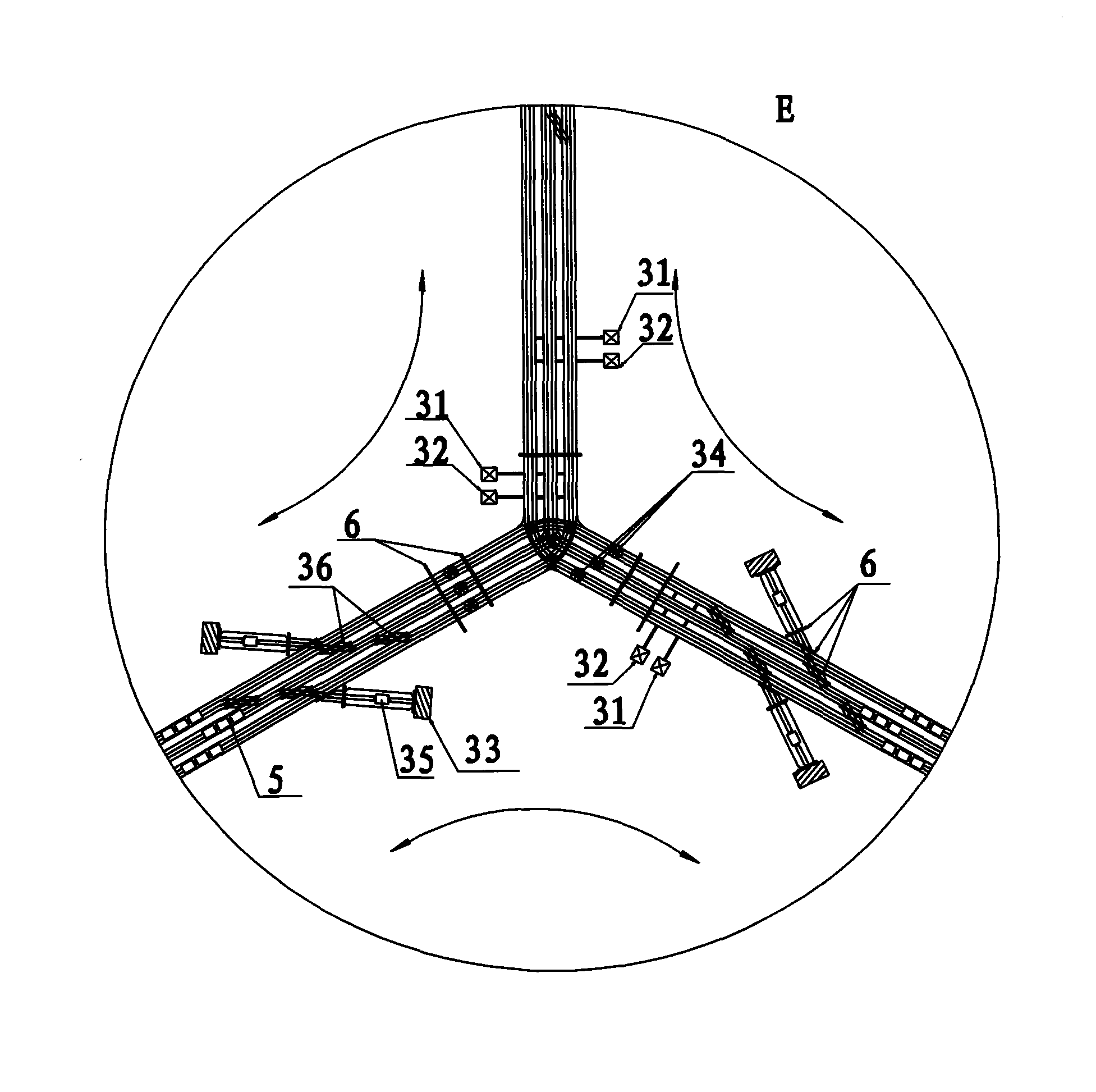

[0019] The intelligent vacuum logistics pipeline conveying system includes A freight yard 1, B freight yard 2 and a vacuum pipeline 3 connecting A and B freight yards. A and B freight yards are respectively equipped with A and B freight yards for integrated dispatching control The center 11, 21 and the electric power stations 12, 22 of the A and B freight yards. The vacuum pipeline 3 includes at least three vacuum pipelines 3 arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com