Novel double-wall storage tank

A storage tank, a new type of technology, applied in the direction of large containers, containers, packaging, etc., can solve the problems of dislocation extrusion, storage tank wall rupture, small force, etc., to achieve sensitive force strength, smooth liquid flow, and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

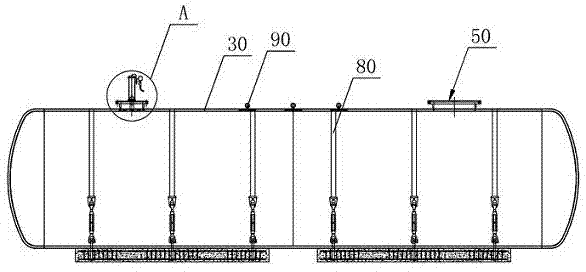

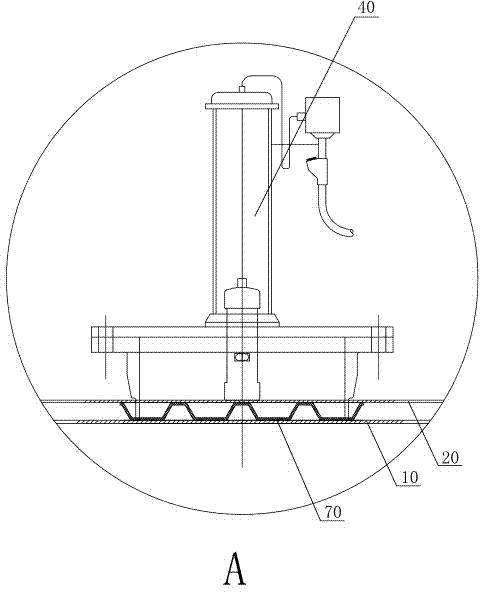

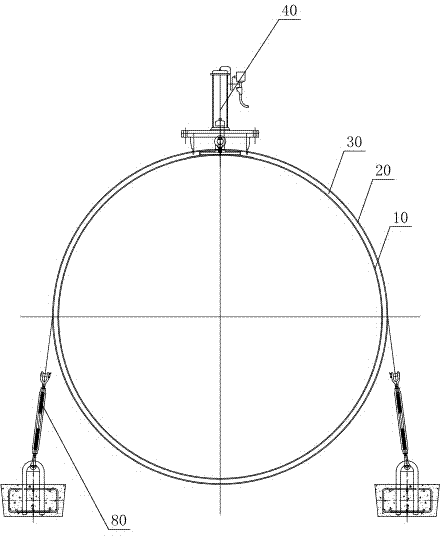

[0016] A new type of double-wall storage tank, such as Figures 1 to 5 As shown, it includes a storage tank body 30 made of inner and outer walls 10, 20, an oil leakage detection device 40 arranged on the storage tank body 30, and a Spatially connected oil ports 50; the inner and outer walls 10, 20 are glass fiber reinforced plastic cylinders; a splint layer 60 is arranged between the inner and outer walls 10, 20, and the splint layer 60 is a glass steel plate body, on which several recessed bodies 70 located on the same side of the plate body are integrally formed; the oil body leakage detection device 40 is connected between the inner and outer wall bodies 10 and 20 In the cavity; the oil port 50 includes an oil inlet 51 and an oil outlet 52 .

[0017] As can be seen from the above, the inner and outer wall bodies 10, 20 and the middle plywood layer 60 are all made of FRP, so that the plywood layer 60 is installed between the inner and outer layer wall bodies 10, 20 without...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com