Method for preparing active porous graphene

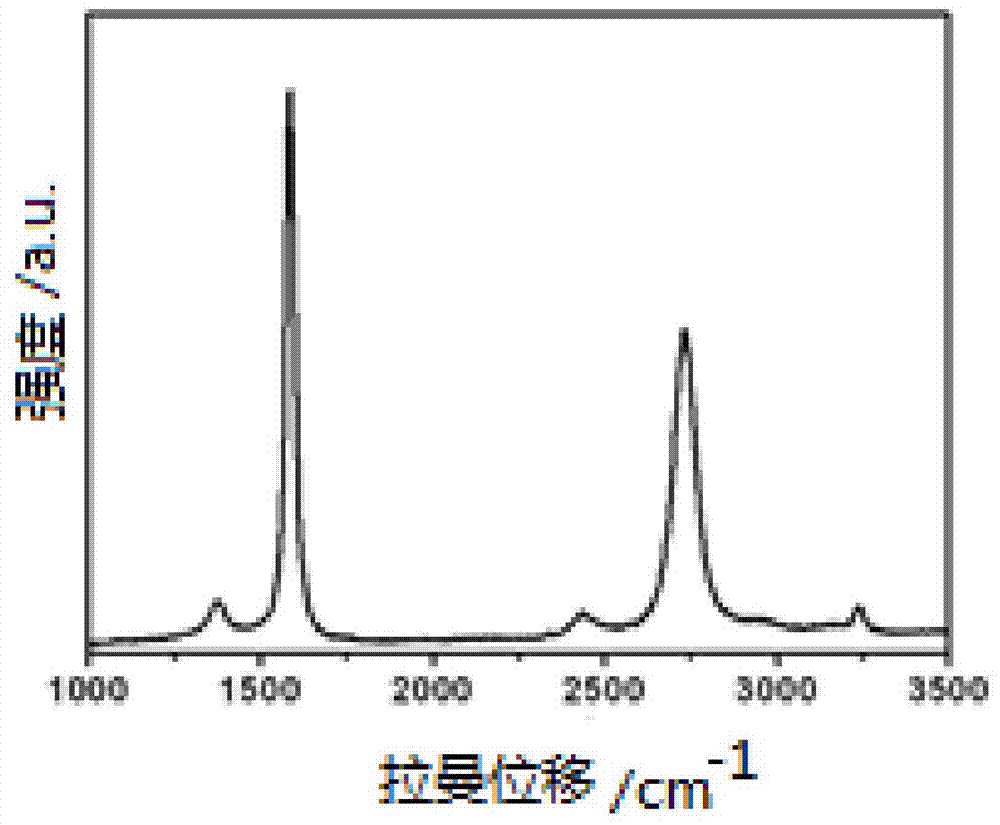

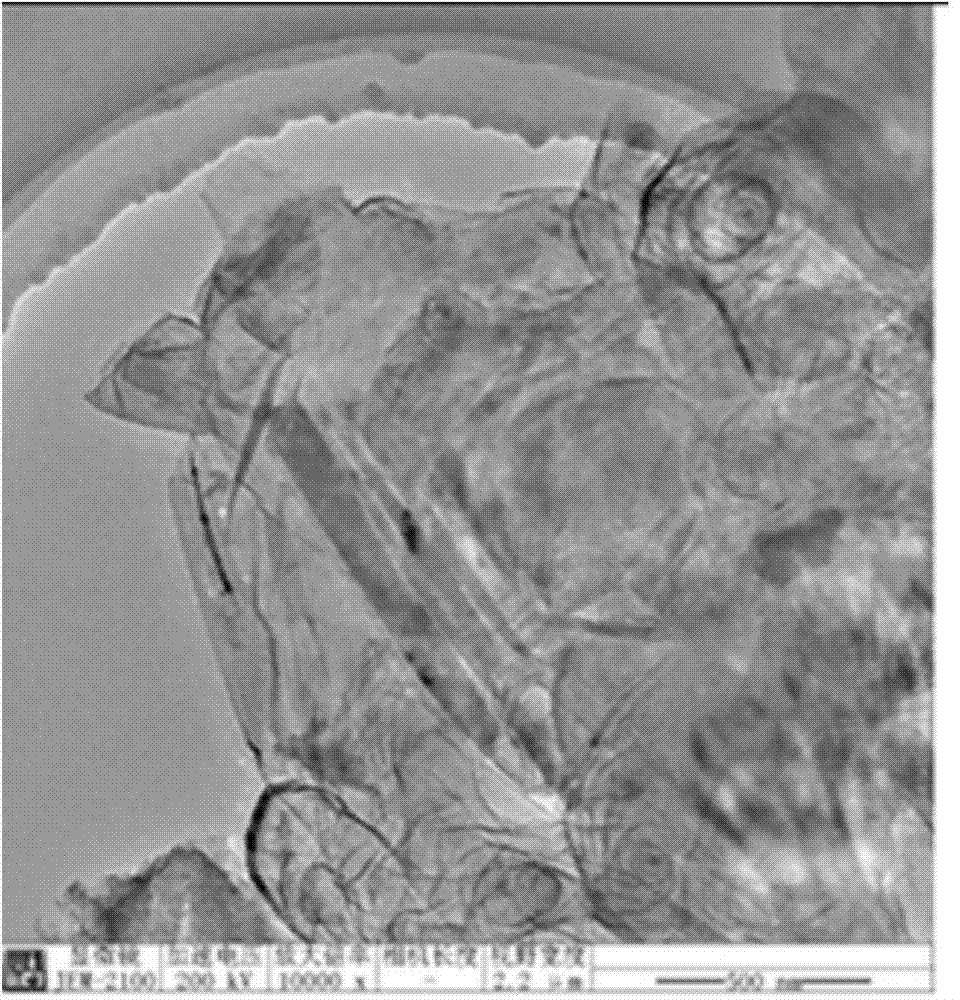

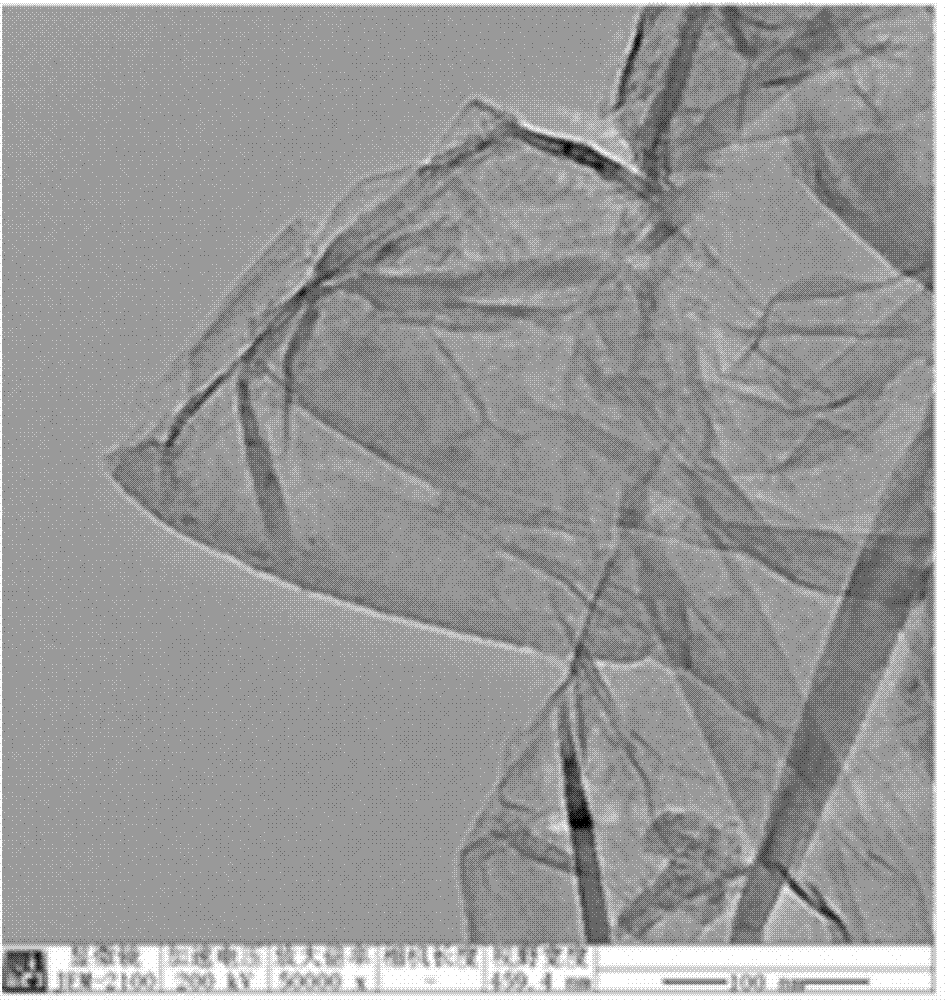

A porous graphene and active technology, applied in the field of graphene, can solve the problems of poor electrical conductivity and unsatisfactory dispersion effect of graphene, and achieve the effect of good electrical conductivity, low cost, and thin sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] At 90° C., hydrolyzing corncobs in sulfuric acid for 10 minutes to obtain lignocellulose, the mass of the sulfuric acid being 3% of the mass of the corncobs;

[0051] At 70°C, the lignocellulose was subjected to acidic sulfite treatment for 1 hour to obtain porous cellulose, the pH value in the acidic sulfite treatment process was 1, the acid was sulfuric acid, and sulfite It is magnesium sulfite, the quality of the sulfuric acid is 4% of the quality of the lignocellulose, and the liquid-solid ratio is 2:1.

Embodiment 2

[0053] At 180°C, hydrolyzing corncobs in nitric acid for 10 hours to obtain lignocellulose, the mass of the nitric acid being 20% of the mass of the corncobs;

[0054] At 180°C, the lignocellulose was subjected to acidic sulfite treatment for 6 hours to obtain porous cellulose, the pH value during the acidic sulfite treatment process was 7, the acid was sulfuric acid, and sulfite It is sodium sulfite, the quality of the sulfuric acid is 30% of the quality of the lignocellulose, and the liquid-solid ratio is 20:1.

[0055] The porous cellulose is bleached with hydrogen peroxide, the mass of the hydrogen peroxide is 5% of the mass of the porous cellulose, the bleaching temperature of the hydrogen peroxide bleach is 100° C., and the bleaching time is 5 hours.

Embodiment 3

[0057] At 130° C., hydrolyzing corncobs in hydrochloric acid for 5 hours to obtain lignocellulose, the mass of the hydrochloric acid being 10% of the mass of the corncobs;

[0058] At 120°C, the lignocellulose was subjected to acidic sulfite treatment for 4 hours to obtain porous cellulose, the pH value in the acidic sulfite treatment process was 3, the acid was sulfuric acid, sulfite It is ammonium sulfite, the quality of the sulfuric acid is 18% of the quality of the lignocellulose, and the liquid-solid ratio is 10:1.

[0059] The porous cellulose is bleached with hydrogen peroxide, the mass of the hydrogen peroxide is 5% of the mass of the porous cellulose, the bleaching temperature of the hydrogen peroxide bleach is 100° C., and the bleaching time is 5 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com