Composite board for building

A composite panel and construction technology, applied in the direction of buildings, building components, building structures, etc., can solve the problems of large load-bearing, excessive application of core materials, poor earthquake resistance, etc., to reduce carbon dioxide emissions, strengthen strength and practicality Life, enhance the effect of compressive and flexural properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention. Apparently, the described embodiments are only some of the embodiments of the present invention, but not all of them.

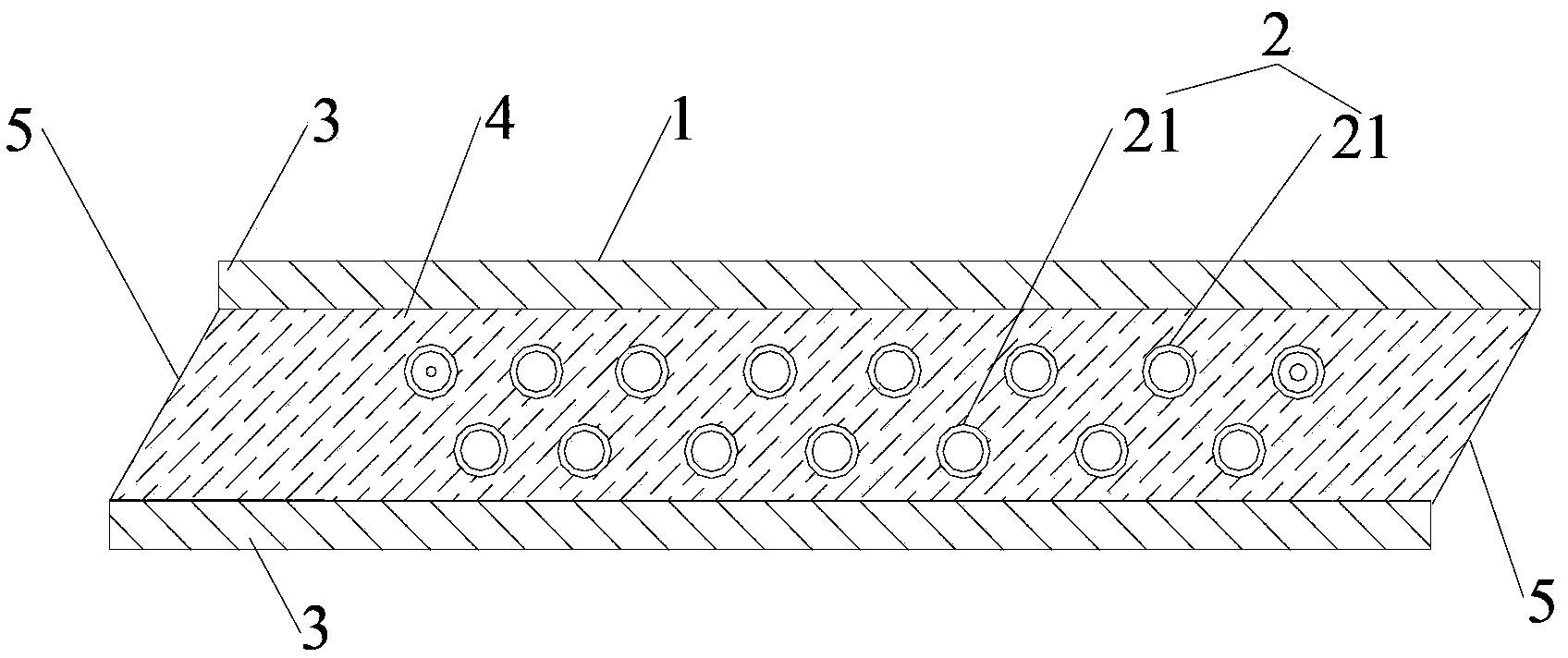

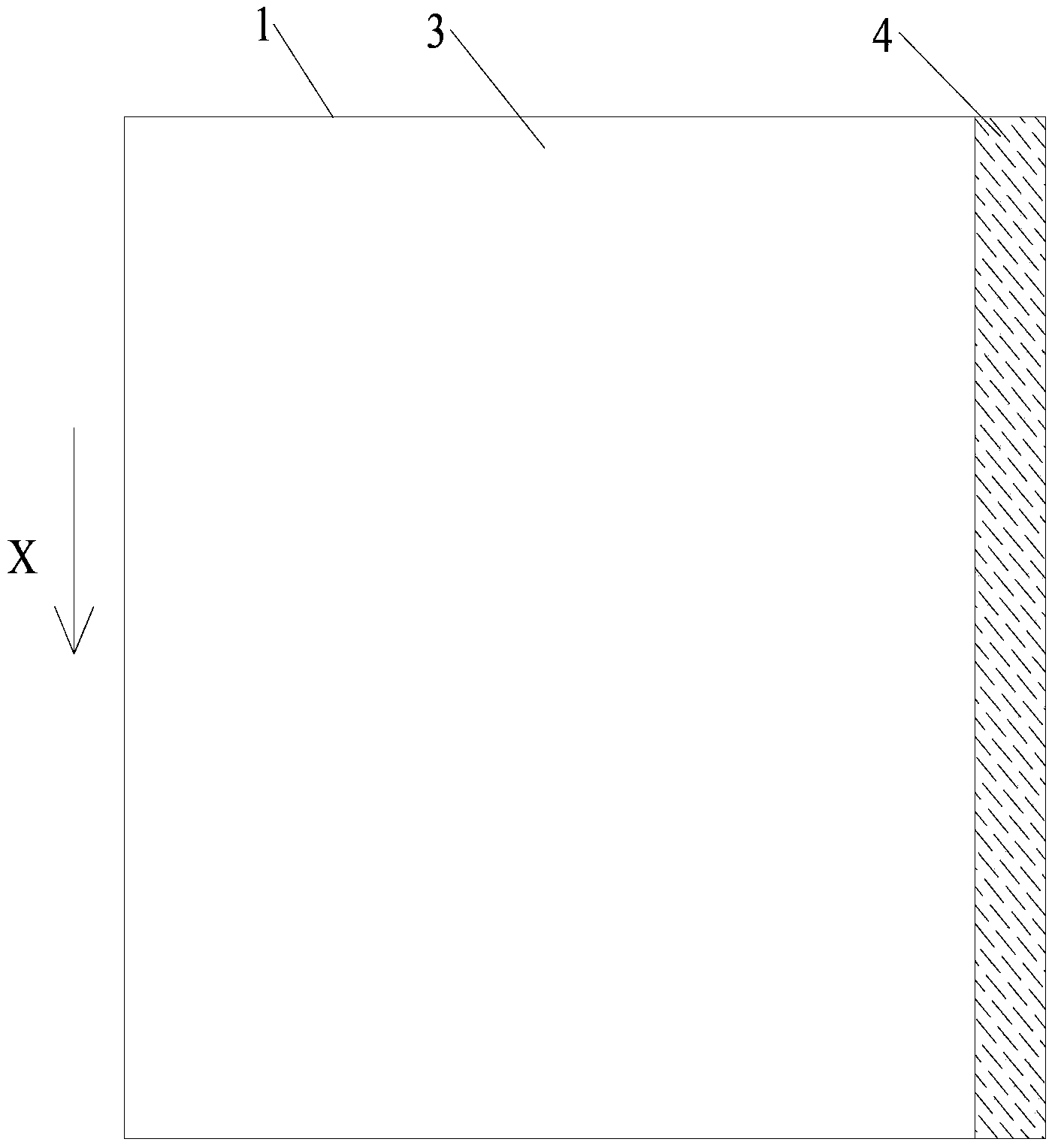

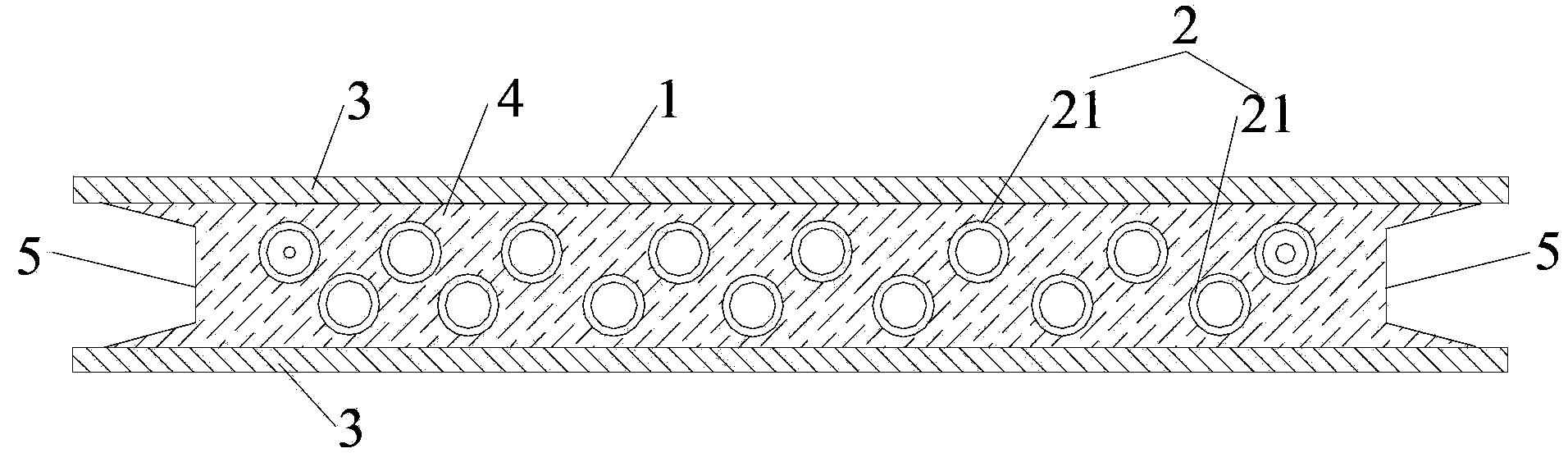

[0032] like figure 1 and figure 2 The composite panel 1 for construction of the shown embodiment includes a porous layer 2, an insulating layer 4 and a non-combustible panel layer 3 placed oppositely, the insulating layer 12 is interposed between the noncombustible panel layers 13, and the porous layer 2 is located in the insulating layer 12. The porous layer 2 is composed of several empty channels 21 of various numbers, sizes and shapes arranged and combined. The cross-section of the hollow channel 21 in the present embodiment is circular, may also be rectangular, or is shaped (such as Figure 5 shown).

[0033] In this embodiment, the hollow channel 21 e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com