Electric vacuum pump with two swinging spherical pistons

A technology of electric vacuum pump and spherical piston, which is applied in variable displacement pump components, pumps, pump components, etc. It can solve the problems of affecting pump performance, piston sealing performance degradation, and piston ring sealing performance degradation, so as to improve service life and reliability. performance, eliminate the possibility of water ingress, and reduce the effect of dynamic unbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

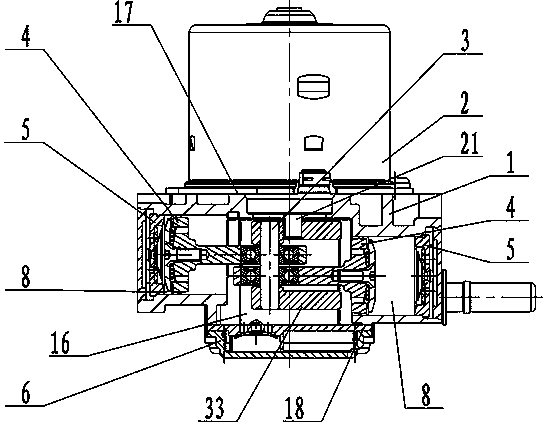

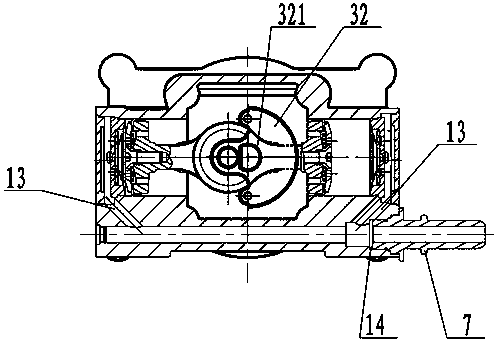

[0022] attached by figure 1 , 2 As shown, the double-swing spherical piston electric vacuum pump includes a pump body 1, a motor 2, an eccentric shaft 3 with a balance weight, two spherical pistons with exhaust valves 4, two intake valves 5, and a Muffler 6 and air pipe joint 7.

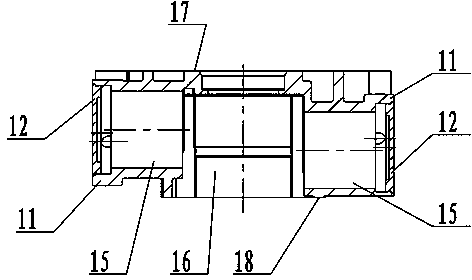

[0023] attached by figure 1 , 2 , 3, and 4, the pump body 1 is a heterogeneous structure formed by aluminum alloy die-casting, and it includes two cylinders 11 with an appropriate distance. An end cap 12 at the outer end of the inner hole of the cylinder, the outer cylinder of the end cap 12 is in interference connection with the inner hole of the cylinder 11 . A through hole 13 is provided in the pump body to communicate with the inner holes of the above-mentioned two cylinders 11 and the air pipe joint installation hole 14 on the surface. One end of the air pipe joint 7 is connected to the air pipe joint installation hole 14 with interference. The inner cavity of 11 is the cylinder barrel 15 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com