Driving mechanism for AOD slag car

A technology of driving mechanism and slag car, which is applied to furnaces, lighting and heating equipment, furnace components, etc., can solve the problems of rope breaking, shutdown, affecting production, etc., and achieves reduction of labor costs, simple structure, and labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

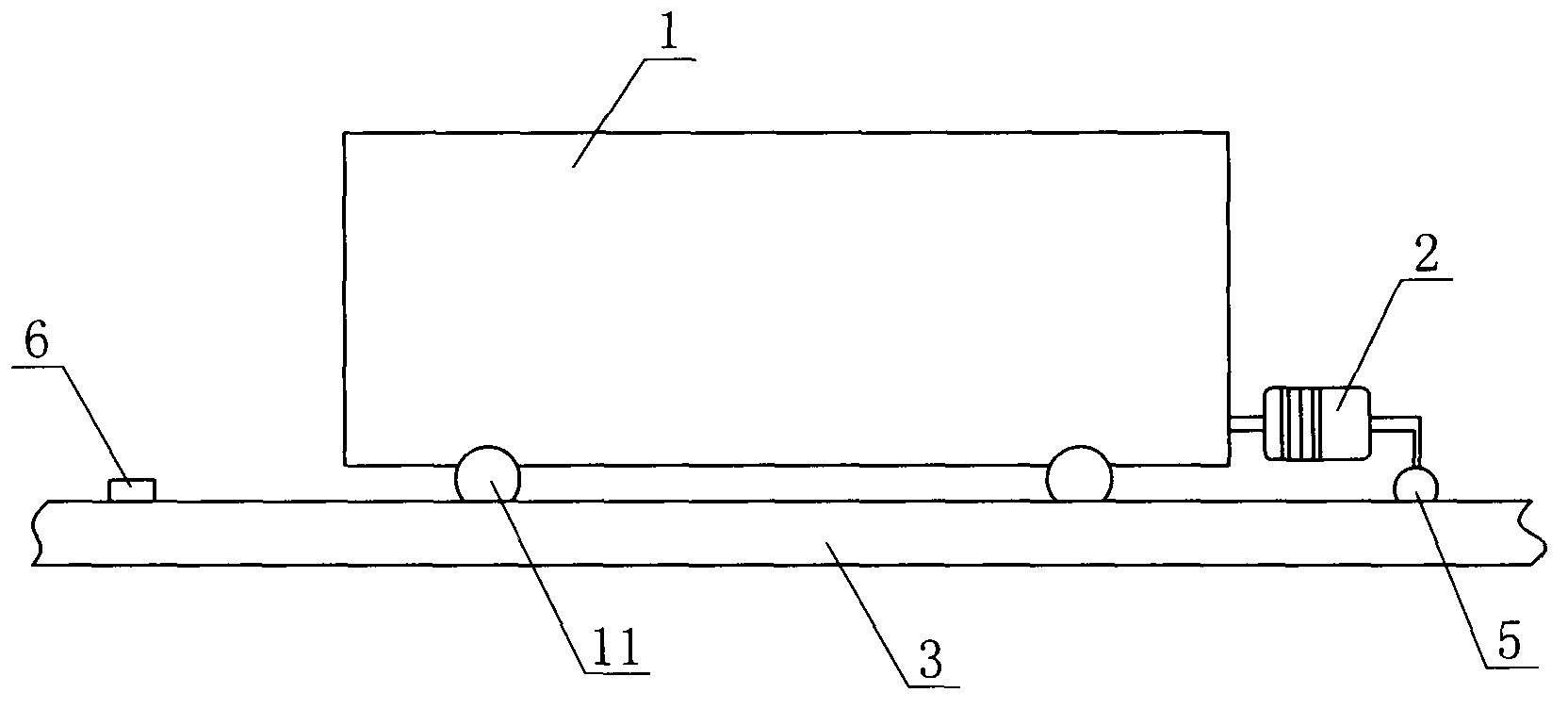

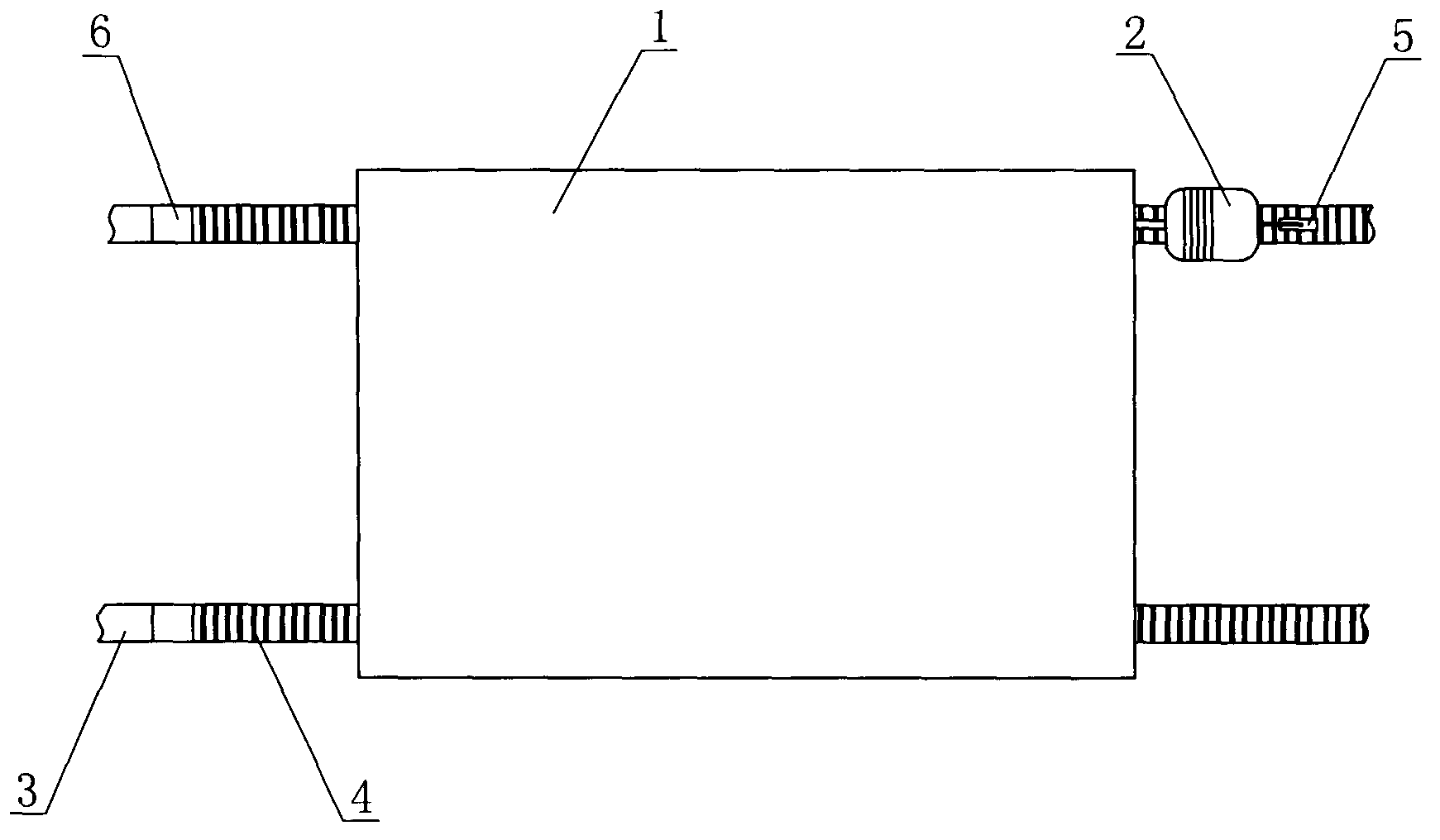

[0020] Example: see figure 1 , 2 As shown, a driving mechanism of an AOD slag truck includes a slag truck 1 and a driving mechanism; the slag truck 1 is connected to the driving mechanism; the driving mechanism includes a motor 2, a guide rail 3, and a The rack 4 on the top and the gear 5 meshing with the rack 4; the output shaft of the motor 2 is connected to the gear 5 through a reducer.

[0021] The end of the guide rail 3 is provided with a limiting plate 6 .

[0022] The bottom of the slag truck 1 is provided with at least four traveling wheels 11 , and the at least four traveling wheels 11 are slidably arranged on the guide rail 3 .

[0023] The rack 4 is a segmented rack.

[0024] Connect the slag truck to the driving mechanism, start the motor, and the motor drives the gear and the rack to drive, thereby driving the slag truck to move forward on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com