A kind of manufacturing method of radial iron core cake

A production method and iron core cake technology, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of high production cost, looseness between sheets, and inability to compress between sheets, so as to reduce the cost of mold production , saving time and effort, and the effect of small gaps between films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

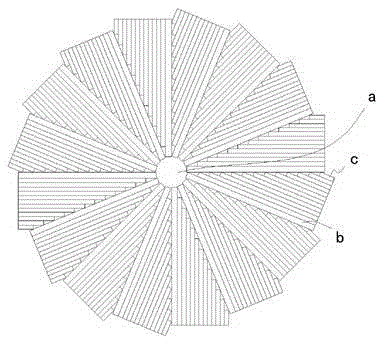

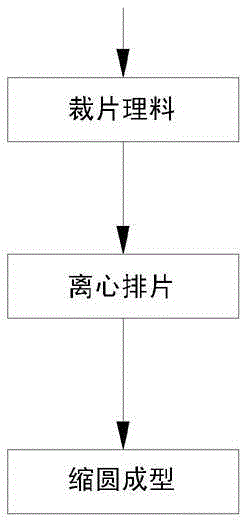

[0018] see image 3 , and combined with figure 1 . This production method has three steps:

[0019] 1. Cutting and sorting materials: Cut magnetic silicon steel sheets of different widths; arrange the magnetic silicon steel sheets from the longest piece b to the shortest piece c in sequence, and organize them into a group of pieces; then, one by one The group is placed in the carrier plate 2 provided with partition partitions 3 according to the height direction, and after forming a radial and loosely arranged sheet material circle, the outer ring 4 is sleeved on the outer contour surface of the sheet material circle;

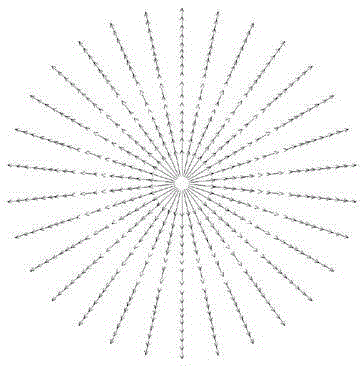

[0020] 2. Centrifugal sheet discharge: place the carrier plate 2 together with the sheet material circle and the outer ring 4 on the rotary tray 1, and rotate the rotary tray 1 for centrifugal sheet discharge;

[0021] 3. Rounding forming: remove the outer ring 4 and the partition plate 3 after the centrifugal sheet arrangement is completed, and insert a cent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com