Anode for lithium secondary battery and lithium secondary battery including same

A negative electrode and electrode technology, which is applied in the field of negative electrodes and lithium secondary batteries containing the negative electrodes, can solve the problems of intensified surface pressing, reduced surface porosity ratio, reduced battery performance and life characteristics, etc., to improve mobility and improve charging characteristics and life characteristics, and the effect of improving porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

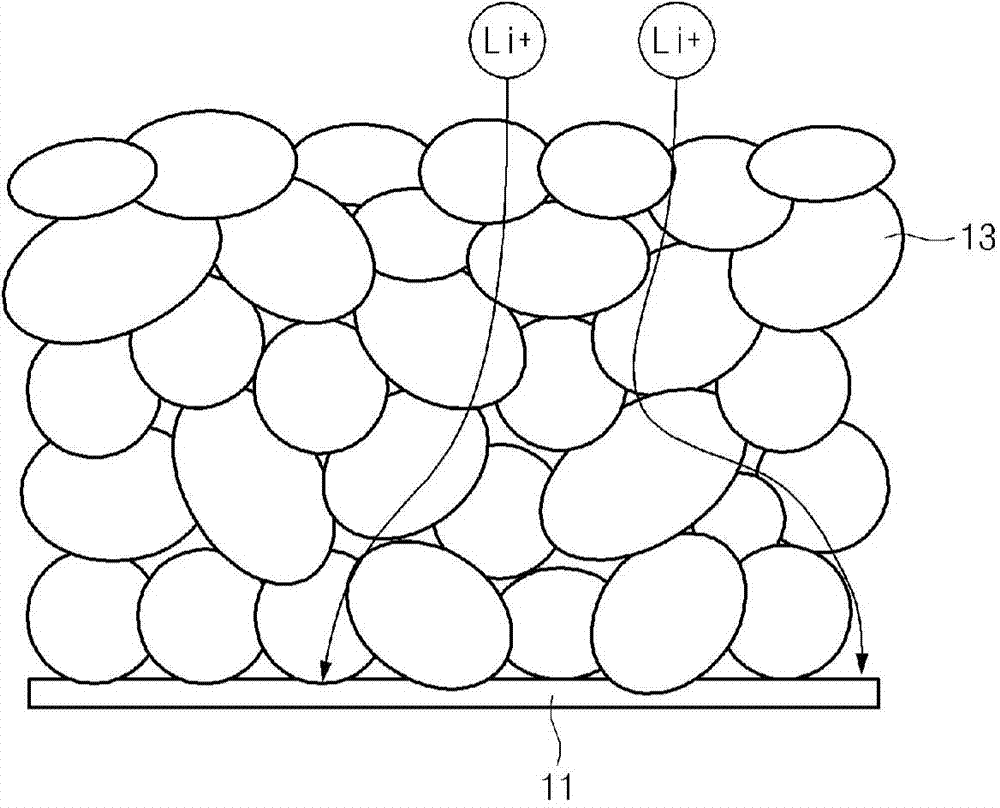

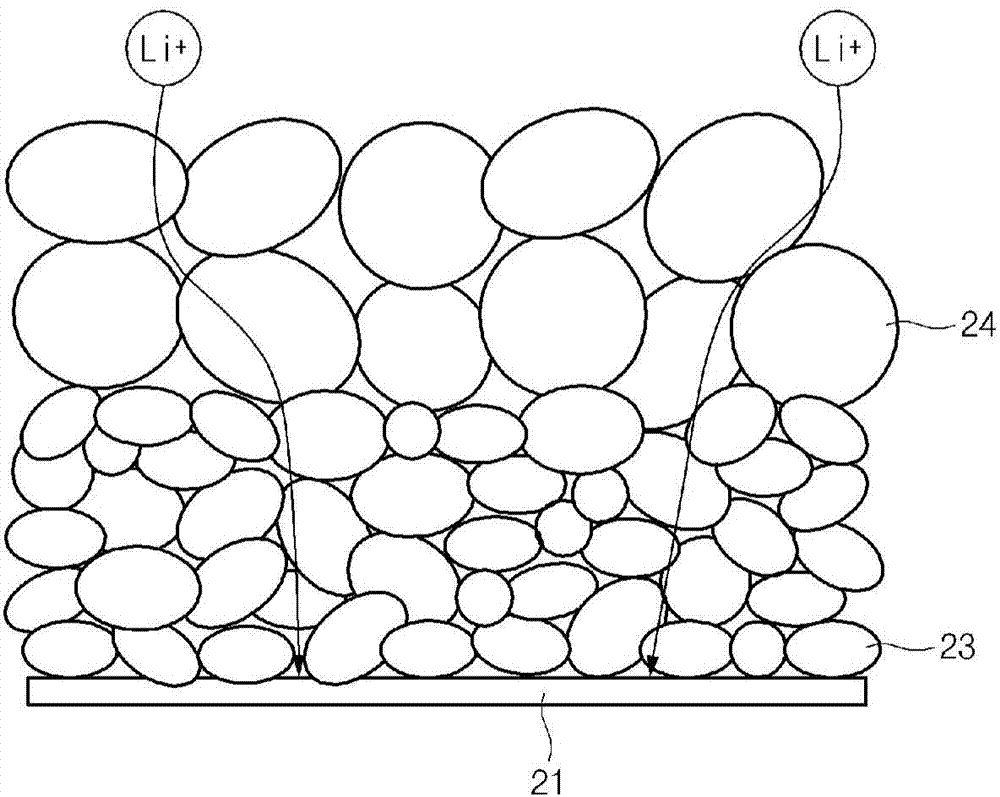

[0042] And, according to an embodiment of the present invention, a method for preparing a negative electrode is provided, the method for preparing the negative electrode includes: coating a first negative electrode active material slurry comprising a first negative electrode active material and a binder resin on an electrode collector the step of forming a negative electrode active material layer by drying the first negative electrode active material slurry; coating the first negative electrode active material layer comprising a second negative electrode active material and a binder resin on the primary negative electrode active material layer Two steps of negative electrode active material slurry; the step of forming a secondary negative electrode active material layer by drying the second negative electrode active material slurry; and forming the primary negative electrode active material layer and the secondary negative electrode active material layer The electrode current c...

Embodiment 1

[0066]Mix when applying the pressure of 12.3MPa negative electrode density is the first negative electrode active material (artificial graphite) 97.3 parts by weight of 1.79g / cc, conductive material (Super-P (conductive carbon black)) 0.7 weight part, thickener (carboxylate) 1.0 parts by weight of methyl cellulose) and 1.0 parts by weight of a binder (styrene-butadiene rubber), thereby preparing the first negative electrode active material slurry.

[0067] Then, mix 97.3 parts by weight of the second negative electrode active material (artificial graphite) of 1.51g / cc when applying the pressure of 12.3MPa, 0.7 parts by weight of the conductive material (Super-P), thickener (carboxymethyl fiber) element) 1.0 parts by weight and binder (styrene-butadiene rubber) 1.0 parts by weight, thus preparing the second negative electrode active material slurry.

[0068] After the above-mentioned first negative electrode active material slurry and the second negative electrode active materi...

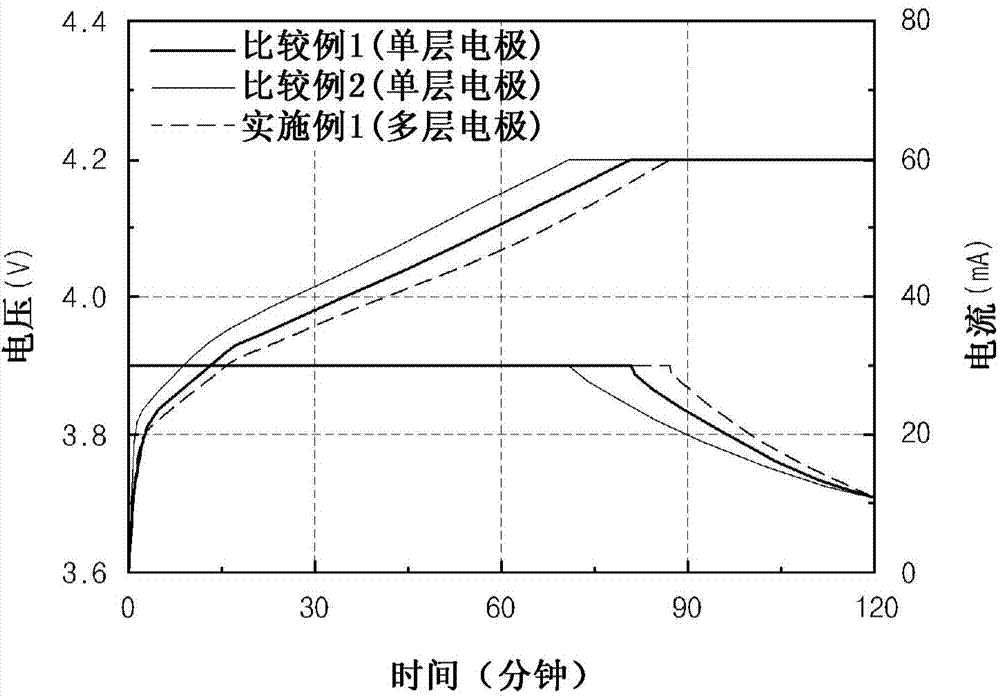

experiment example 1

[0077] (Experimental example 1: Determination of average particle size by compaction density meter)

[0078] The measurement of the compacted density of the negative electrode active material particles prepared in Example 1 and Comparative Examples 1 and 2 was performed using a powder resistance measuring instrument MCP-PD51 of Mitsubishi Chemical Corporation.

[0079] In the case of the above-mentioned powder resistance measuring instrument, a predetermined amount of positive electrode active material powder is placed in a cylinder-type load cell, and the pressure is continuously applied. At this time, the density of the particles when pressed is measured. Therefore, the greater the strength of the negative electrode active material particles, the less they are pressed under the same pressure, thus exhibiting a lower density. At this time, the applied pressure is about 12 to 16 MPa.

[0080] The average particle size of the negative electrode active materials prepared in Exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com