Brazing Method of π Die Rod in Four-Wing RF Quadrupole Field Accelerator Cavity by Hydrogen Furnace

A technology of radio frequency quadrupole field and brazing method, which is applied in the direction of welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of affecting the manufacturing level of RFQ accelerator cavity, low welding success rate, deformation of π die rod, etc. Achieve the effects of improving vacuum sealing performance, simplifying processing procedures, and increasing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

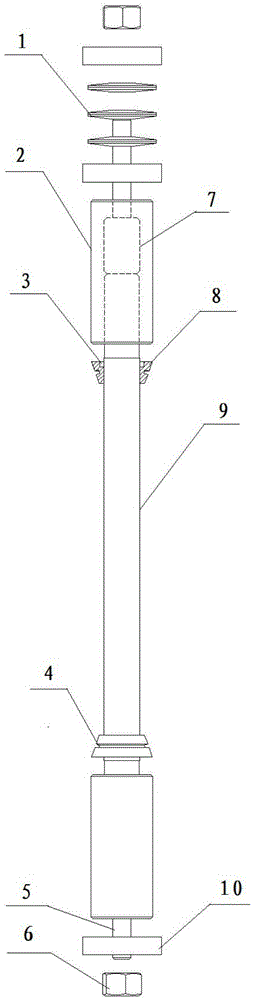

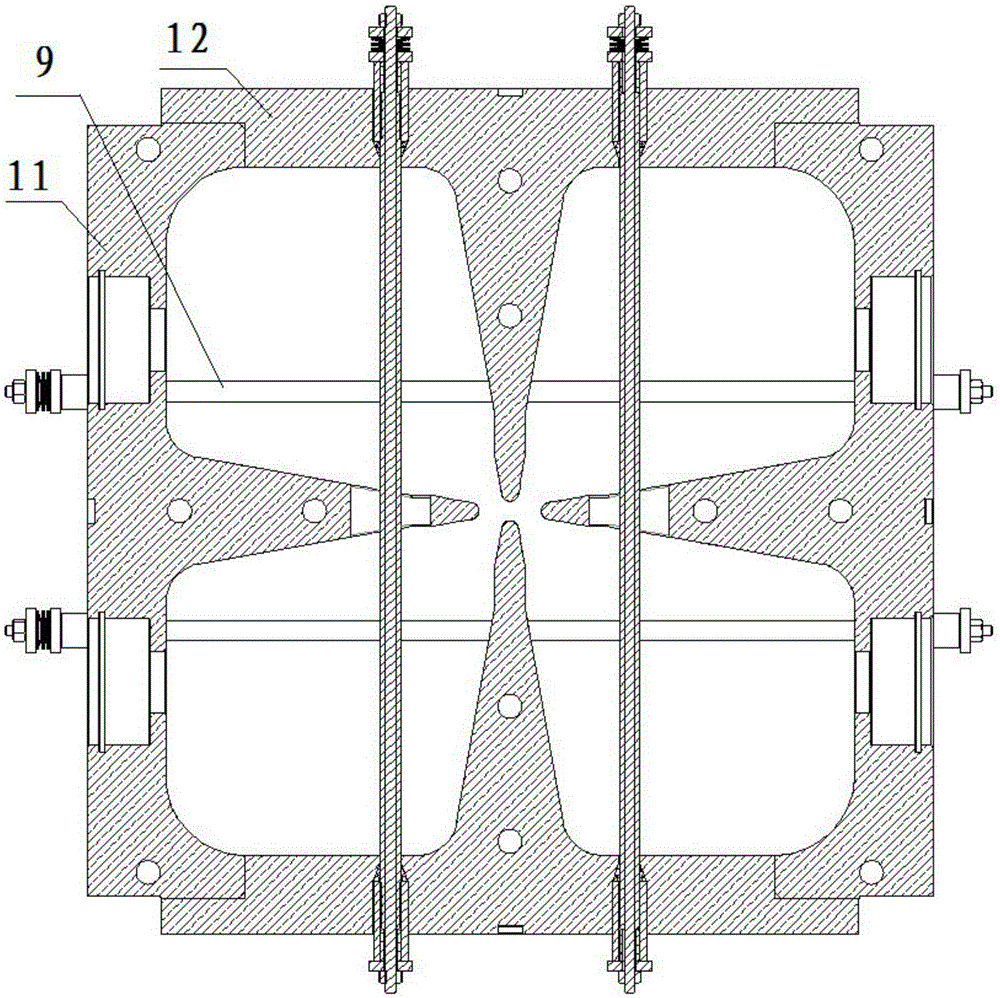

[0020] Such as figure 1 with 2 As shown, in the four-wing type radio frequency quadrupole field accelerator cavity π mold rod hydrogen furnace brazing method, the upper end of the π mold rod 9 is provided with a stainless steel compensation ring 7, and the stainless steel compensation ring 7 is externally provided with a ceramic ring 2, π The upper end of the die rod 9 is also provided with a high temperature resistant spring washer 1, the π die rod 9 is provided with a fully threaded screw 5, the lower end of the fully threaded screw 5 is equipped with a stainless steel gasket 10 through a brass nut 6, and the π die rod 9 is welded Taper sleeve 8 is arranged, and its characteristic is to comprise the following ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com