Method for manufacturing high-precision single vane of four-vane radio frequency quadrupole field cavity

A technology of a radio frequency quadrupole field and a manufacturing method, which is applied to the manufacturing field of a high-precision single-wing of a four-wing radio frequency quadrupole field cavity, can solve the problems of low precision, poor consistency of the single-wing, affecting the manufacturing level of the RFQ single-wing, etc. To achieve the effect of high surface finish and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

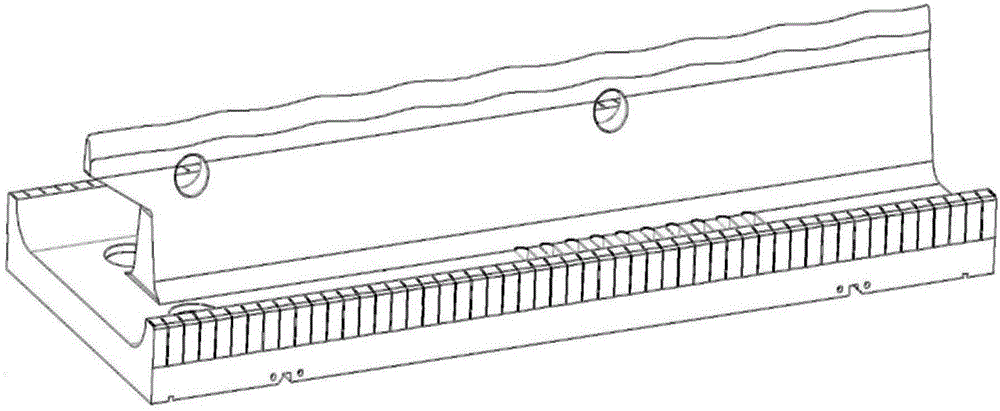

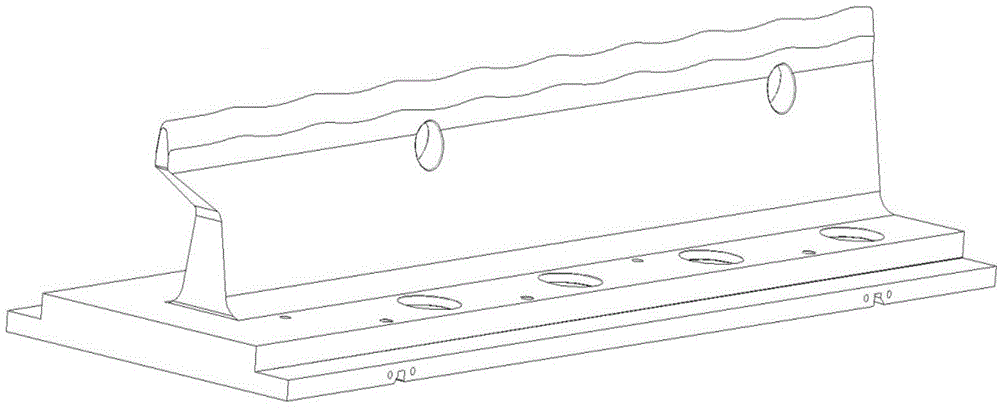

[0028] Such as Figures 1 to 3 As shown, the manufacturing method of the described four-wing type radio frequency quadrupole field cavity high-precision single wing is characterized in that it comprises the following steps:

[0029] (1), a section of four-wing radio frequency quadrupole field cavity is composed of four single wings, which are two horizontal single wings with exactly the same size and two vertical single wings with the same size;

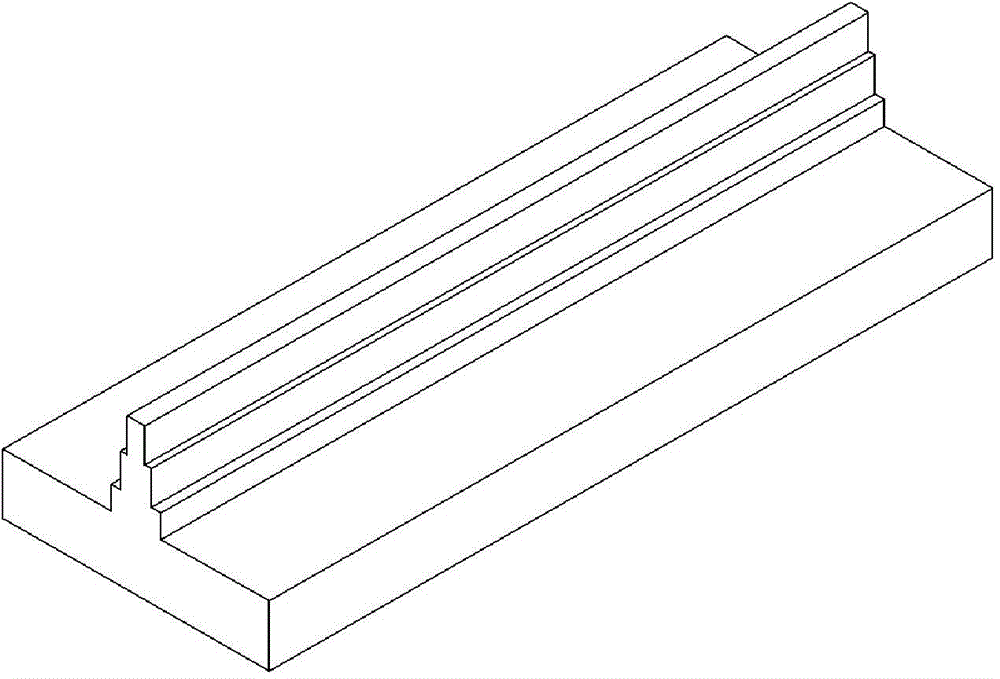

[0030] (2) Using a band sawing machine, cut the cuboid oxygen-free copper raw material with a size of 1100mm (length) x 410mm (width) x 225mm (height) into a T shape, and cut 1100mm along the length direction on the left and right sides of the symmetrical axis in the width...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com