Thermoplastic cellular sheet material and preparation method thereof

A thermoplastic and honeycomb technology, applied in the direction of chemical instruments and methods, lamination, lamination devices, etc., can solve the problems of low production efficiency of hot wire cutting, high resistance of electric heating wire cutting, complex structure, etc., and improve the effect of air extraction and heat dissipation , avoid slack, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing a thermoplastic honeycomb plate, comprising the steps of:

[0028] 1) manufacturing a double-layer composite pipe, the inner layer of the double-layer composite pipe is a high melting point material layer, the outer layer of the double layer composite pipe is a low melting point material layer, and the melting point of the low melting point material layer is lower than the melting point of the high melting point material layer;

[0029] 2) A plurality of double-layer composite pipes are arranged in an orderly bundle, and the outer layer of the double-layer composite pipe is melted by heating while the inner layer is not melted. After cooling, the outer layers of the adjacent double-layer composite pipes are bonded together to form honeycomb body;

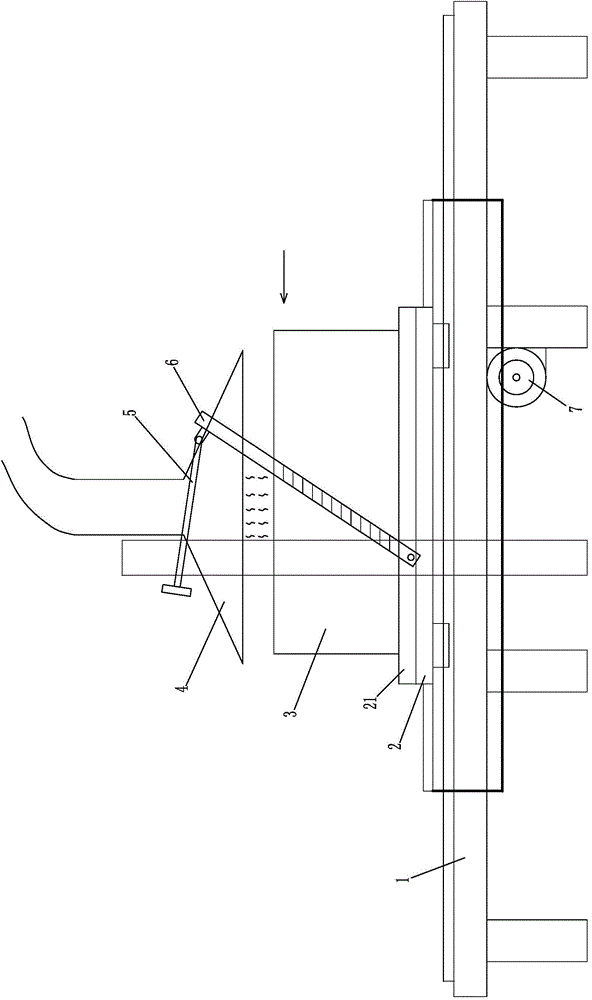

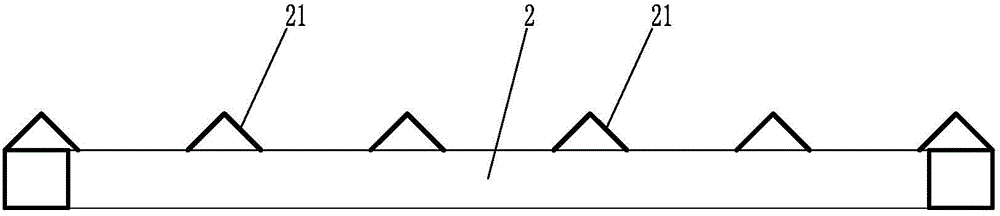

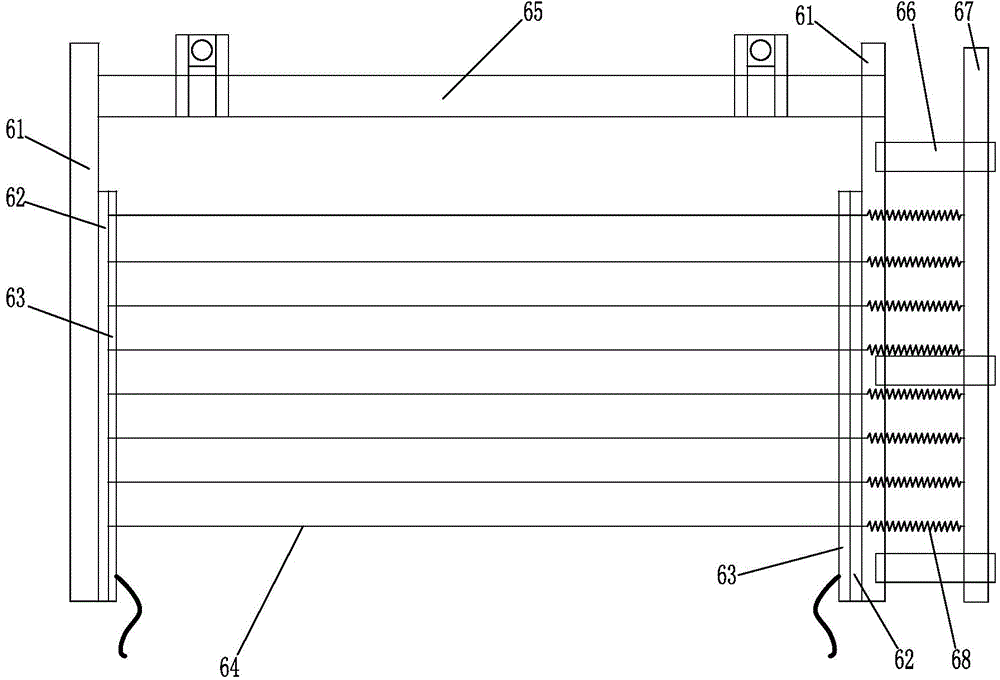

[0030] 3) The honeycomb body is cut along the cross-section of the double-layer composite pipe by a hot wire cutting machine, thereby obtaining a plate-shaped honeycomb substrate; wherein, such as figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com