Synthesis method of 4-Hydroxythiobenzamide

A technology of hydroxythiobenzamide and hydroxybenzamide, which is applied in the field of synthesis of p-hydroxythiobenzamide, can solve the problems of difficult industrialization and low processing costs, achieve low cost, easy operation, and realize industrial production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

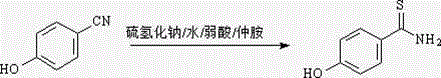

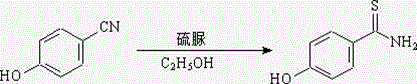

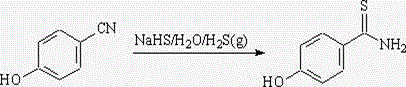

Method used

Image

Examples

Embodiment 1

[0030] Put 150mL of 28% concentrated ammonia water and 8.6g (0.060mol) of methyl p-hydroxybenzoate in the reaction kettle. Under the condition of stirring, control the temperature at 100-120°C and keep it warm for the reaction. TLC detection shows that the reaction is complete. Concentrate the final reaction solution in a rotary evaporator to twice the amount of the feed, filter and dry to obtain a white solid that is p-hydroxybenzamide 7.63g (0.055mol), yield rate 97.8%, HPLC purity 99.1%

Embodiment 2

[0032] Put 150mL of 28% concentrated ammonia water and 8.6g (0.060mol) of methyl p-hydroxybenzoate in the reaction kettle. Under the condition of stirring, control the temperature at 100-120°C and keep it warm for reaction. TLC detection shows that the reaction is complete. Concentrate the final reaction solution in a rotary evaporator to 1.5 times the amount of feed, and then separate and dry by suction filtration to obtain a white solid that is p-hydroxybenzamide 7.64g (0.056mol), yield 98.0%, HPLC purity 96.3%.

Embodiment 3

[0034] Put 100mL of 28% concentrated ammonia water and 8.6g (0.060mol) of methyl p-hydroxybenzoate in the reaction kettle. Under the condition of stirring, control the temperature at 100~120°C and keep the reaction. TLC detects that the reaction is complete. Concentrate the final reaction liquid in a rotary evaporator to twice the amount of feed, and then separate and dry by suction filtration to obtain 7.54 g (0.055 mol) of white solid p-hydroxybenzamide, with a yield of 96.7% and a purity of 97.2% by HPLC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com