Solvent-based two-component elastic polyester/polyurethane sandstorm resistant train coating and preparation method thereof

An elastic polyester, two-component technology, applied in the field of coatings, can solve the problems of unsuitability for train body painting, low gloss, poor weather resistance, etc., and achieve the effect of convenient packaging, transportation, installation and operation, and good storage stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

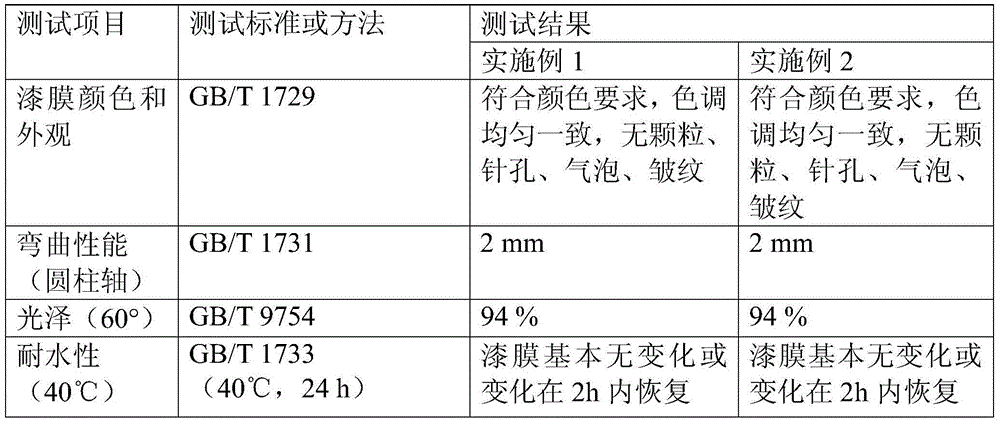

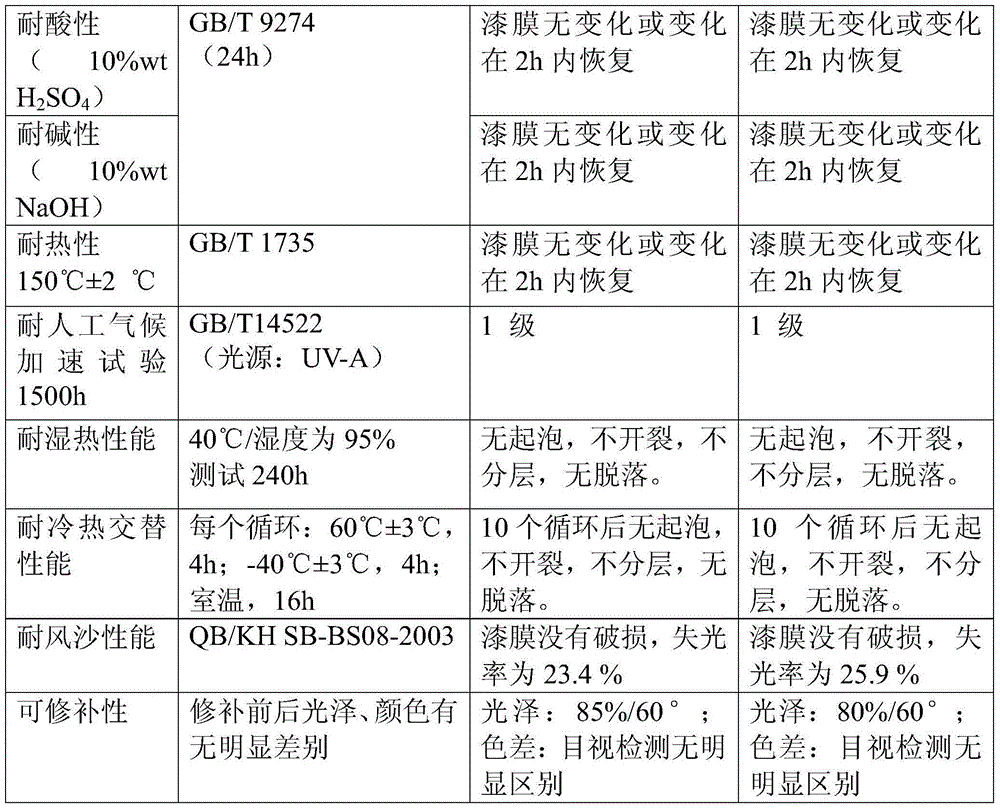

Examples

Embodiment 1

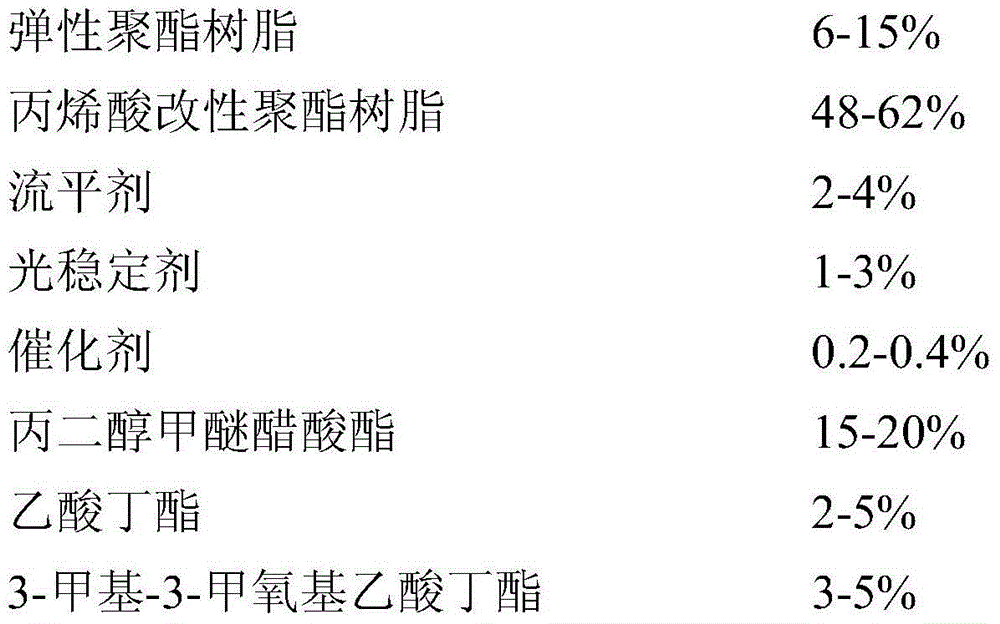

[0037] The invention is a preparation method of a solvent-based two-component elastic polyester / polyurethane anti-wind and sand train coating. The following process steps are adopted, and the formula ratio is calculated by weight percentage:

[0038] (1) Preparation of component A main agent:

[0039] ① Premix 7% of elastic polyester resin, 60% of acrylic modified polyester resin, and 20% of propylene glycol methyl ether acetate, and stir and disperse at 800 rpm for 10 minutes;

[0040] 2. Under stirring state at 800 rpm, add 3% of 3-methyl-3-methoxybutyl acetate, 2% of leveling agent, 2.8% of light stabilizer, and 0.2% of catalyst to the mixture obtained in step 1. Stir and disperse for 15 minutes at a speed of 1500 rpm;

[0041] ③Under stirring at 800 rpm, add 5% butyl acetate to the mixture obtained in step ② to adjust the viscosity to become a finished product. Viscosity: 30±3 seconds; the viscosity is measured with a DIN No. 4 cup at a temperature of 23°C; the solid con...

Embodiment 2

[0046] The invention is a preparation method of a solvent-based two-component elastic polyester / polyurethane anti-wind and sand train coating. The following process steps are adopted, and the formula ratio is calculated by weight percentage:

[0047] ① Pre-mix 10% elastic polyester resin, 56% acrylic modified polyester resin, and 20% propylene glycol methyl ether acetate, and stir and disperse for 8 minutes at a speed of 1000 rpm;

[0048] 2. Under stirring state at 800 rpm, add 4% of 3-methyl-3-methoxybutyl acetate, 2.2% of leveling agent, 2.5% of light stabilizer, and 0.3% of catalyst to the mixture obtained in step 1. Stir and disperse for 10 minutes at a speed of 2000 rpm;

[0049] ③ Under stirring at 700 rpm, add 5% butyl acetate to the mixture obtained in step ② to adjust the viscosity to become a finished product. Viscosity: 30±3 seconds; the viscosity is measured with a DIN No.4 cup at a temperature of 23°C; the solid content is 58%;

[0050] (2) Preparation of compo...

Embodiment 3

[0054] The invention is a preparation method of a solvent-based two-component elastic polyester / polyurethane anti-wind and sand train coating. The following process steps are adopted, and the formula ratio is calculated by weight percentage:

[0055] (1) Preparation of component A main agent:

[0056] ① Pre-mix 12% elastic polyester resin, 55% acrylic modified polyester resin, and 18% propylene glycol methyl ether acetate, and stir and disperse for 6 minutes at a speed of 1200 rpm;

[0057]2. Under stirring at 700 rpm, add 5% of 3-methyl-3-methoxybutyl acetate, 4% of leveling agent, 2% of light stabilizer, and 0.4% of catalyst to the mixture obtained in step 1. Stir and disperse at a speed of 1800 rpm for 12 minutes;

[0058] ③Under stirring at 700 rpm, add 3.6% butyl acetate to the mixture obtained in step ②, and adjust the viscosity to become a finished product. Viscosity: 30±3 seconds; the viscosity is measured with a DIN No.4 cup at a temperature of 23°C; the solid conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com