Method for large-scale cooperative disposal of aging household garbage in landfill through cement kiln

A technology for co-processing and domestic waste, applied in the direction of combustion methods, incinerators, solid waste removal, etc., can solve problems that affect the normal production and product quality of cement plants, high content of non-combustible components, and production cannot be carried out, etc., to achieve The effect of expanding the circular economy industrial chain, large-scale waste disposal, and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

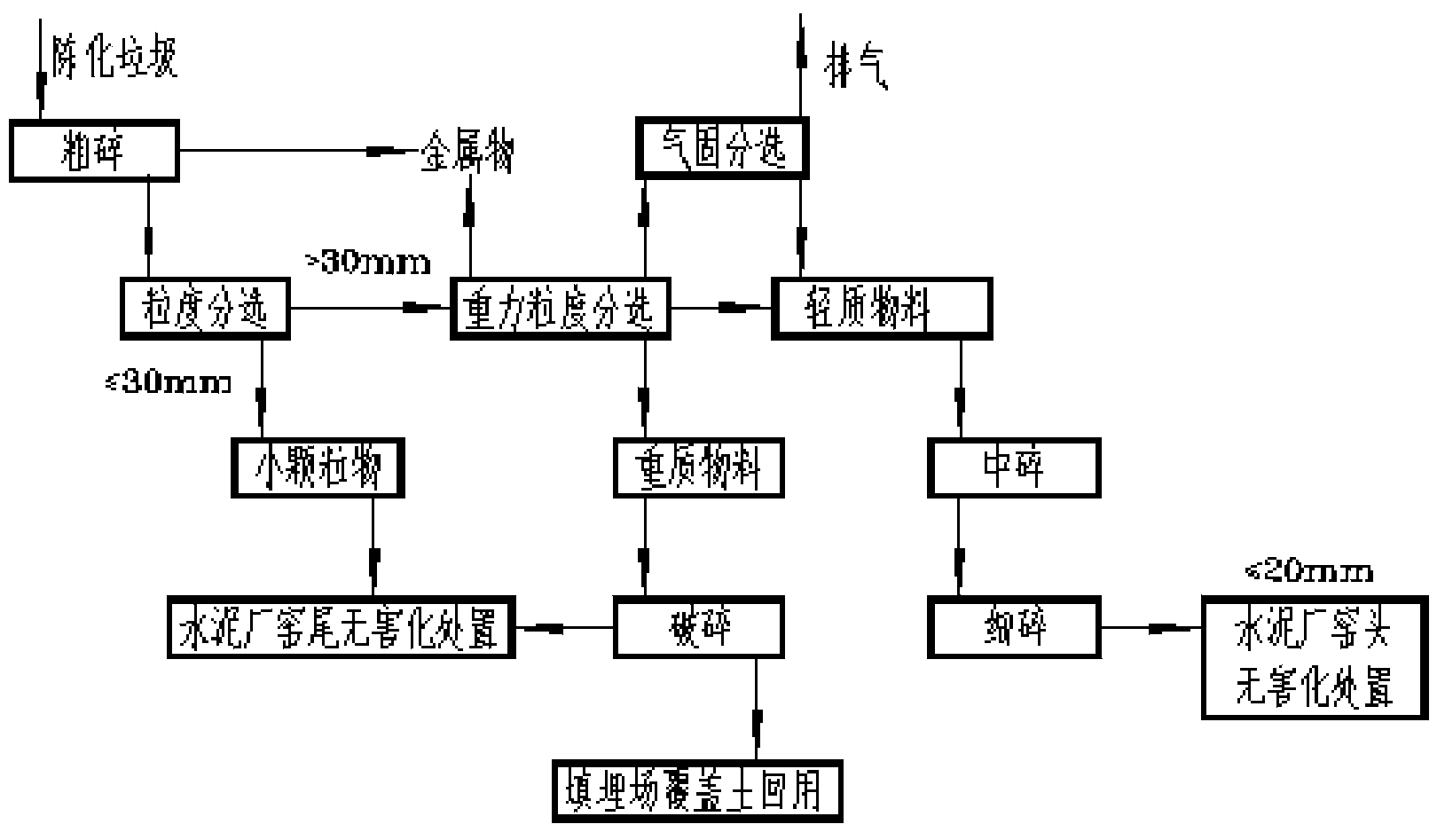

[0033] Such as figure 1 As shown, a method for large-scale co-processing of aged domestic waste in landfills using cement kilns consists of the following steps in sequence:

[0034] 1) Coarse crushing: A certain batch of 200kg municipal solid waste landfill that has undergone natural aging is subjected to coarse crushing and metal objects are recovered for particle size separation. The weight after separation is 198.9kg. Composed of rubber and plastic, dust, gravel, textiles, wood and bamboo, stones, glass, and ceramics.

[0035] 2) Particle size sorting: Garbage with a particle size > 30mm is further subjected to gravity particle size sorting, with a weight of 32.5kg. The main components are rubber and plastic, textiles, wood and bamboo, stones, glass, ceramics, and small particle garbage with a particle size ≤ 30mm Feed to dry process cement kiln kiln tail as all cement raw materials for direct incineration, weighing 166.4kg, mainly composed of lime soil, gravel and other s...

Embodiment 2

[0042] A method for large-scale co-processing of aged domestic waste in landfills using cement kilns, which consists of the following steps in sequence:

[0043] 1) Coarse crushing: A certain batch of 200kg municipal solid waste landfill that has undergone natural aging is subjected to coarse crushing and metal objects are recovered for particle size separation. The weight after separation is 198.5kg, mainly Composed of rubber and plastic, dust, gravel, textiles, wood and bamboo, stones, glass, and ceramics.

[0044] 2) Particle size sorting: Garbage with a particle size > 30mm is further subjected to gravity particle size sorting, with a weight of 31.8kg. The main components are rubber and plastic, textiles, wood and bamboo, stones, glass, ceramics, and small particle garbage with a particle size ≤ 30mm Feed into dry process cement kiln kiln tail as all cement raw materials for direct incineration, weighing 166.7kg, mainly composed of lime soil, gravel and other small impurit...

Embodiment 3

[0051] A method for large-scale co-processing of aged domestic waste in landfills using cement kilns, which consists of the following steps in sequence:

[0052] 1) Coarse crushing: A certain batch of 200kg of municipal solid waste landfill that has undergone natural aging is subjected to coarse crushing and metal objects are recovered for particle size separation. The weight after sorting is 197.6kg, mainly Composed of rubber and plastic, dust, gravel, textiles, wood and bamboo, stones, glass, and ceramics.

[0053] 2) Particle size sorting: Garbage with a particle size > 30mm is further subjected to gravity particle size sorting, with a weight of 32.2kg. The main components are rubber and plastic, textiles, wood and bamboo, stones, glass, ceramics, and small particle garbage with a particle size ≤ 30mm Feed to the tail of the dry process cement kiln as all cement raw materials for direct incineration, weighing 165.4kg, mainly composed of lime soil, gravel and other small imp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com