Powder material drying and cooling integrated equipment

A technology for drying and cooling powder materials, applied in drying solid materials, lighting and heating equipment, drying, etc., can solve the problems of low energy utilization, increased investment costs, high energy consumption, etc., and achieve good drying and cooling effects, The effect of increasing the utilization of energy and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

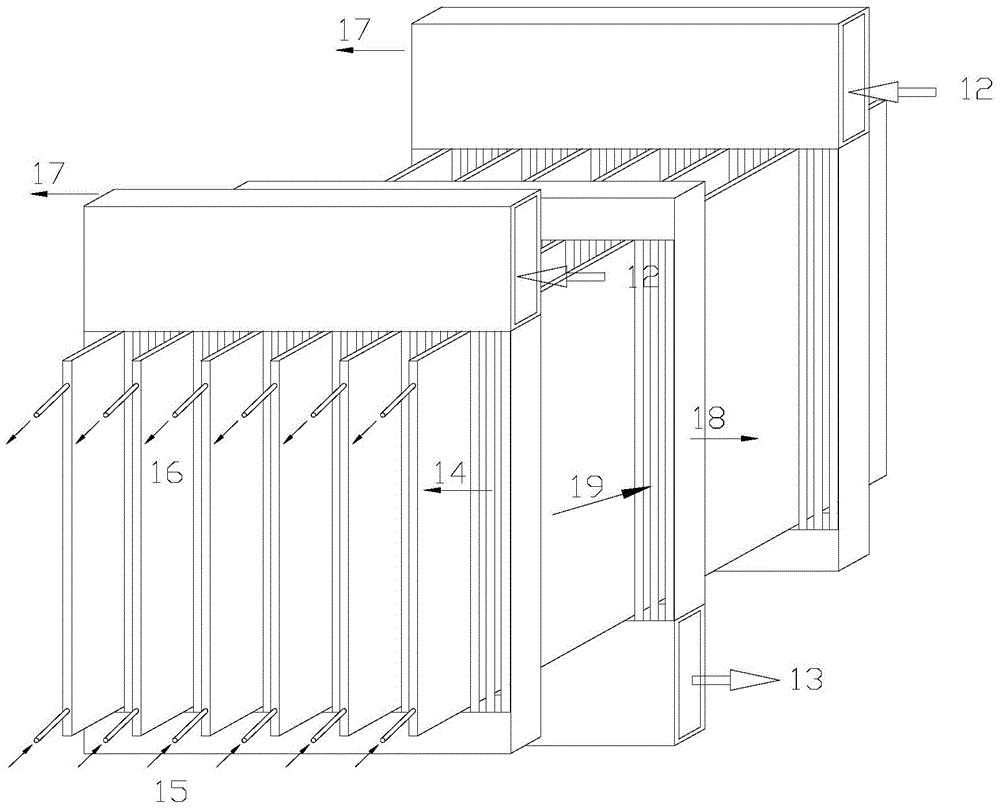

[0036] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0037] In this technical solution, the "cross-flow air" refers to the hot air passing through the material in a direction perpendicular to the flow of the material to be dried, which does not have the same flow direction as the material.

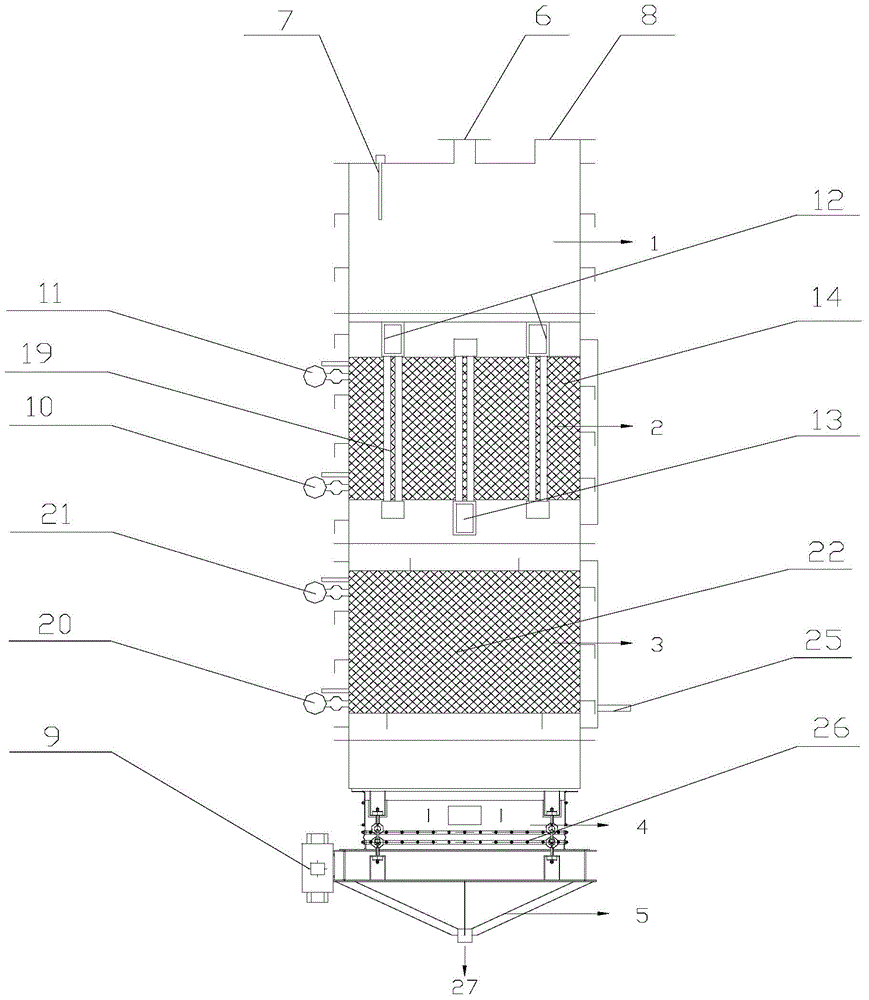

[0038] Depend on figure 1 As shown, in this embodiment, what the present invention describes is a drying and cooling equipment for powder materials. The equipment has a vertical structure and includes a cylindrical shell, and the shell is sequentially fed from top to bottom. Box 1, drying box 2, cooling box 3 and discharge box 4.

[0039] Depend on figure 1 As shown, the top of the feed box 1 is provided with a feed port 6, and a feed pipe is arranged in the feed port, and the powder material can enter the feed box 1 through the feed pipe with a slide pipe or ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com