Bottom radiating zone-control polyimide fiber drier

A polyimide fiber, zone control technology, applied in the direction of dryer, drying, heating device, etc., can solve the problems such as easy winding of the tow on the operator's arm, no safety hazard, difficult to remove, etc. Observe and remove tow entanglement, no safety hazards, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below through specific embodiments.

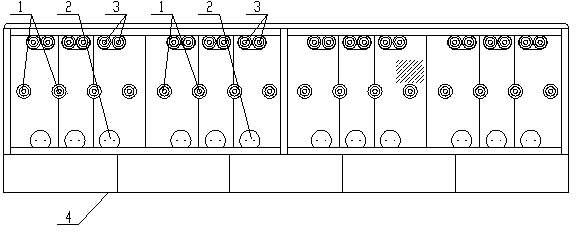

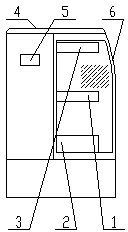

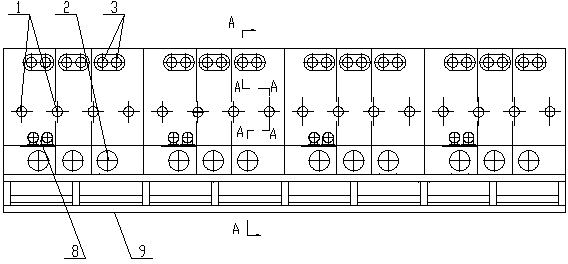

[0025] refer to Figure 1 to Figure 7, the present invention a kind of polyimide fiber drying machine that the heat dissipation zone of the bottom controls, and it comprises frame 9, big driving roller 2, the first small driving roller 3, the second small driving roller 1, transmission device 14, power unit 8. Radiator 13, temperature control device, protective cover 4 and control panel 5, described frame 9 is provided with underframe 12, is fixedly connected support frame 15 above underframe 12, and frame 9 is divided into several districts, each The underframe 12 built-in supporting plate of each district, the bottom of support frame 15 is provided with several first coaxial through holes, and the top of each district is provided with several groups, every group of two second coaxial through holes, the top of each district Several third coaxial through holes are set between the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com