A two-stage combined ballistic ceramic unit

A combination and ceramic technology, applied to the structure of armor plates, armor, protective equipment, etc., can solve the problems of high density, achieve the effects of reducing surface density, firm bonding, and reducing penetration speed and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

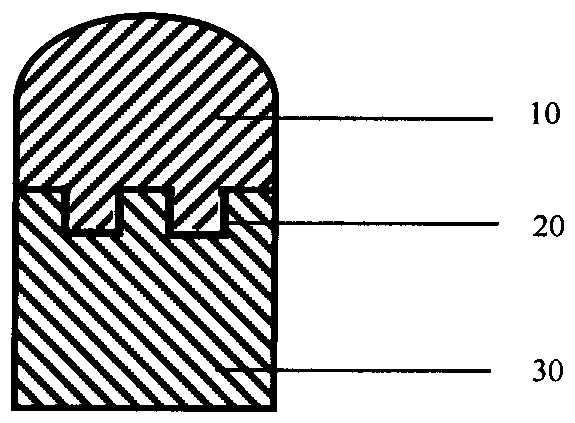

Embodiment 1

[0012] The upper part of the alumina ceramic is a cylindrical ceramic with a height of 10mm, the radius of the cylindrical part is 20mm, and the radius of the top bulging surface is 12mm. The lower part of the boron carbide ceramic is a cylindrical ceramic with a height of 8mm, and the radius of the cylindrical part is 20mm. The upper and lower structures are inlaid with 2 pillars, the height of the pillars is 3mm. Use epoxy resin AB glue to firmly bond the upper and lower materials. After curing, the height of the ballistic unit of the overall material is 18mm, and the surface density is 61~67kg / m. 2 . The monolithic ceramic units are arranged in an orderly manner, and each column is bonded with silicone rubber to finally form a square flat plate with a length and width of 150mm.

Embodiment 2

[0014] The upper part of the alumina ceramic is a cylindrical ceramic with a height of 9mm, the radius of the cylindrical part is 16mm, and the radius of the top bulging surface is 12mm. The lower part of the boron carbide ceramic is a cylindrical ceramic with a height of 12mm, and the radius of the cylindrical part is 16mm. The upper and lower structures are inlaid with a column, and the height of the column is 4mm. Use epoxy resin AB glue to firmly bond the upper and lower materials. After curing, the height of the ballistic unit of the overall material is 21mm, and the surface density is 55-60kg / m. 2 . The monolithic ceramic units are arranged in an orderly manner, and each column is bonded with silicone rubber to finally form a square flat plate with a length and width of 150mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com