Treated copper foil, copper clad laminate and printed wiring board using the treated copper foil

A technology of copper clad layer and processing layer, which is applied in the field of processing copper foil, can solve the problems of increased transmission loss, longer current propagation distance, etc., and achieves the effect of high peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

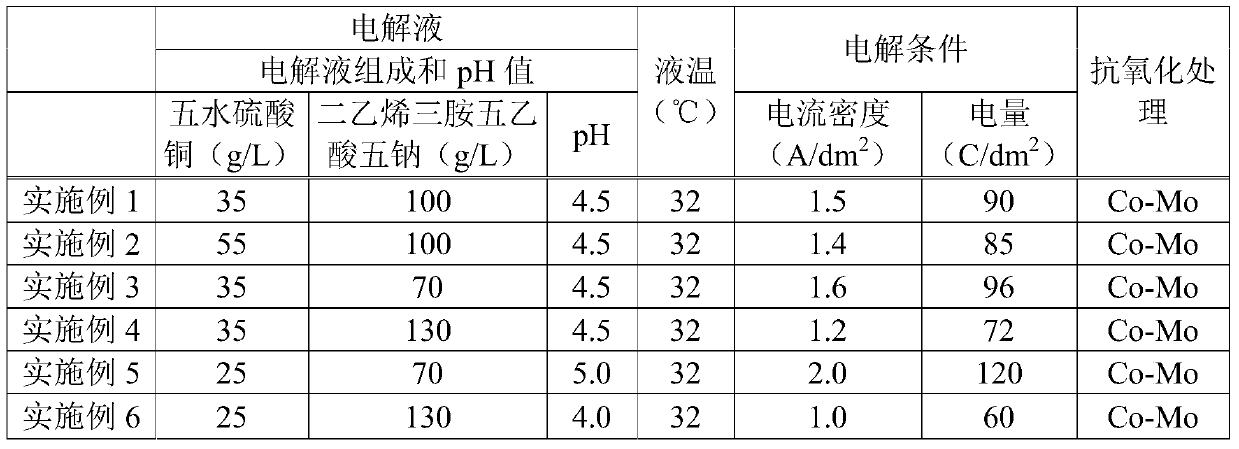

[0122]

[0123] As the electrolytic solution, aqueous solutions prepared to the concentration, pH and liquid temperature of copper sulfate pentahydrate and pentasodium diethylenetriaminepentaacetate shown in Table 1, respectively, were used. In addition, the pH was adjusted using sulfuric acid.

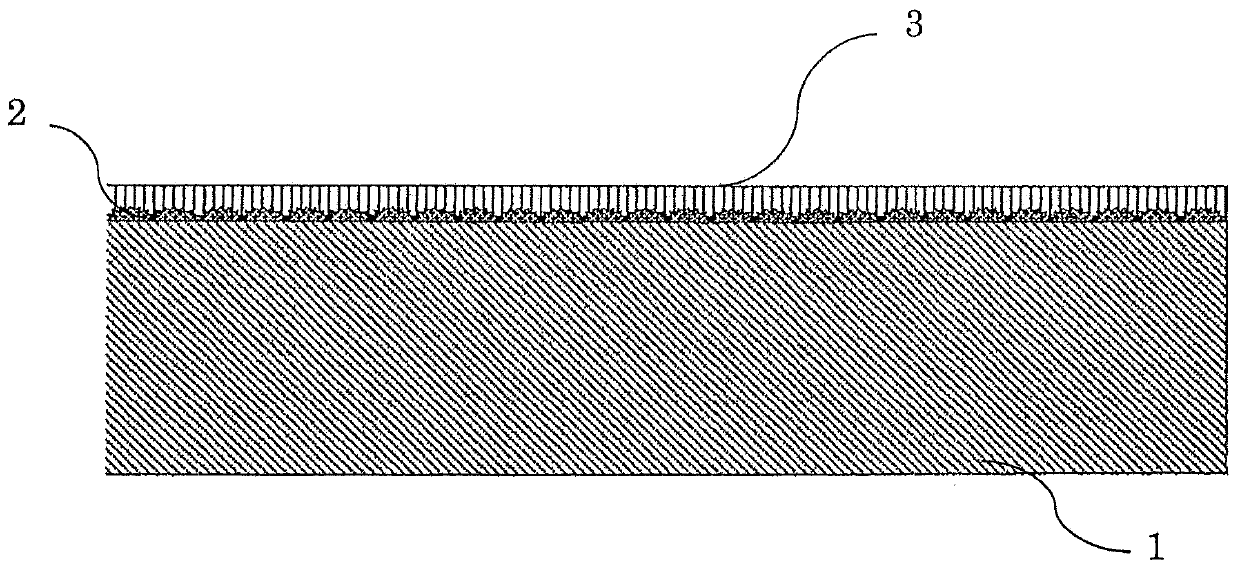

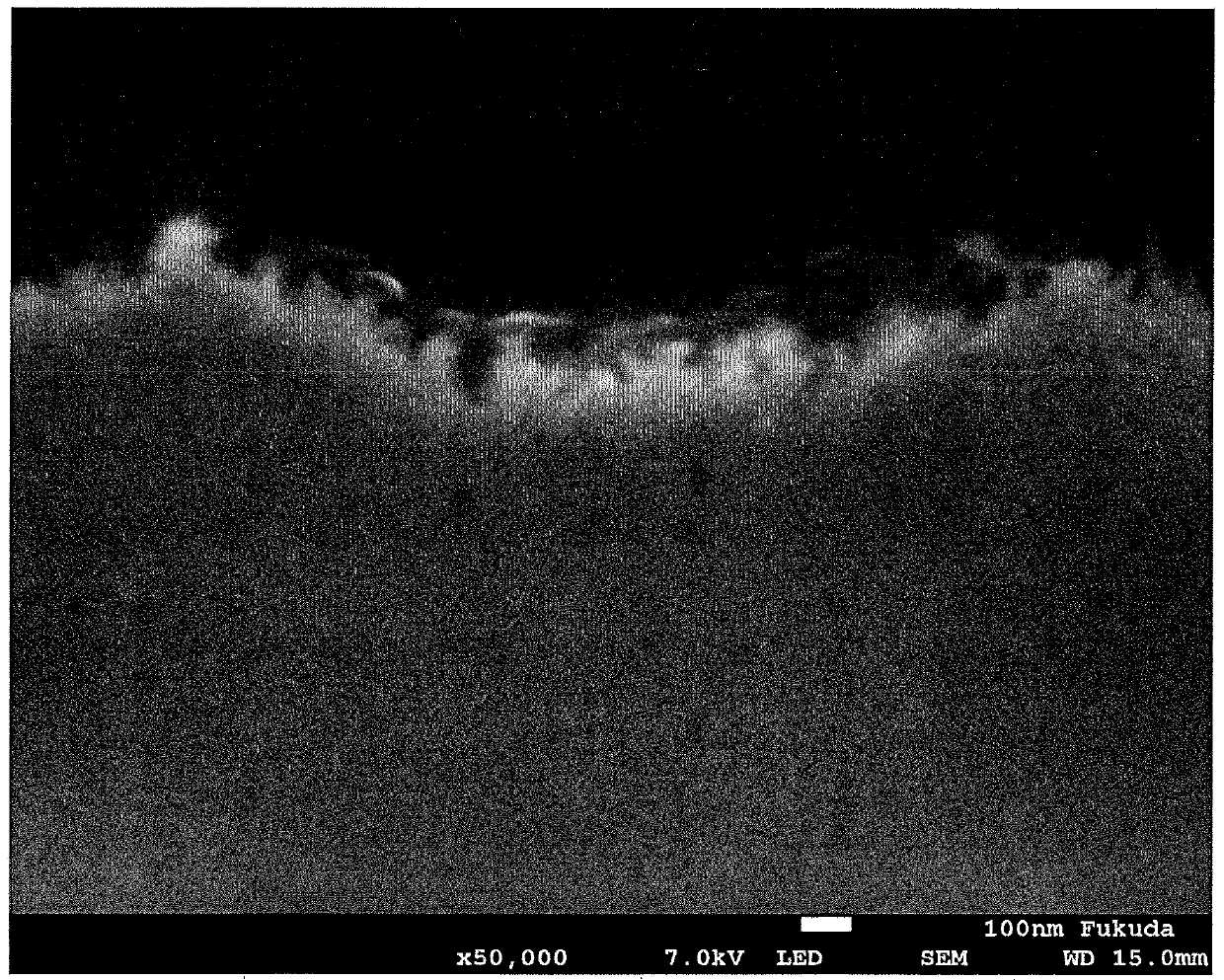

[0124] In the electrolyte, the titanium coated with the platinum group metal oxide is used as the anode, and the untreated copper foil is used as the cathode for immersion, and the two electrodes are electrolyzed under the electrolysis conditions shown in Table 1. A resin-induced permeation layer is formed on one side of the copper foil.

[0125]

[0126] Used as an anode in an aqueous solution containing 38g / L cobalt sulfate heptahydrate, 23g / L sodium molybdate dihydrate, 45g / L trisodium citrate dihydrate, and 80g / L sodium sulfate at pH 5.6 and liquid temperature 30°C The surface of titanium is coated with platinum group metal oxide, and the cathode uses a treated copper foil wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com