Method for determining equilibrium moisture content of tobacco leaf

A water content and balance technology, applied in measuring devices, material analysis through optical means, instruments, etc., can solve time-consuming and labor-intensive problems, achieve non-destructive analysis, suitable for batch testing, and rapid data acquisition technical support.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

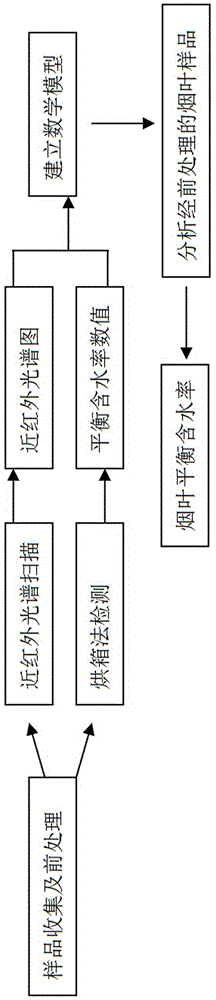

[0022] Such as figure 1 As shown, the method for measuring the equilibrium moisture content of tobacco leaves in this example includes the following steps: (1) Take more than 30 pieces of flue-cured tobacco leaves, first rehydrate, draw stems, and then dry the flue-cured tobacco leaves in a blast drying oven at 35 ° C, dry Finally, the flue-cured tobacco leaves are crushed with a multi-functional grinder and passed through a 40-mesh sieve; (2) The sieved flue-cured tobacco leaf powder is placed in a constant temperature and humidity box with a temperature of (21-23) °C and a humidity of (57-63)%. (3) Take the flue-cured tobacco leaf powder balanced in step (2) and put it into the sample cup of the near-infrared spectrometer, so that the thickness of the flue-cured tobacco leaf powder sample spread in the sample cup is consistent, and the thickness is not less than 5mm , use the near-infrared spectrometer to scan the flue-cured tobacco leaf powder in the sample cup, and collect...

Embodiment 2

[0024] The method for measuring the equilibrium moisture content of tobacco leaves in this embodiment includes the following steps: (1) Take more than 30 pieces of C3F flue-cured tobacco leaves, first rehydrate, and draw stems, and then dry the flue-cured tobacco leaves in a blast drying oven at 40 ° C. After drying, Use a multi-functional pulverizer to crush the flue-cured tobacco leaves and pass through an 80-mesh sieve; (2) Put the sifted flue-cured tobacco leaf powder in a constant temperature and humidity box with a temperature of (21-23) °C and a humidity of (57-63)%. Balance for more than 48 hours; (3) Take the flue-cured tobacco powder balanced in step (2) and put it into the sample cup of the near-infrared spectrometer, so that the thickness of the flue-cured tobacco leaf powder in the sample cup is not less than 5mm, and the flue-cured tobacco leaf powder sample is in the sample cup. The thickness of the middle shop is consistent, and the near-infrared spectrum of the...

Embodiment 3

[0026] The method for measuring the equilibrium moisture content of tobacco leaves in this embodiment includes the following steps: (1) Take more than 30 pieces of X2F flue-cured tobacco leaves, first rehydrate, and draw stems, and then dry the flue-cured tobacco leaves in a blast drying oven at 45°C. After drying, Use a multi-functional pulverizer to crush the flue-cured tobacco leaves and pass through a 20-mesh sieve; (2) Put the sieved flue-cured tobacco leaf powder in a constant temperature and humidity box with a temperature of (21-23) °C and a humidity of (57-63)%. Balance for more than 48 hours; (3) Take the flue-cured tobacco leaf powder balanced in step (2) and put it into the sample cup of the near-infrared spectrometer, so that the thickness of the flue-cured tobacco leaf powder sample spread in the sample cup is consistent, and the thickness is not less than 5mm. The near-infrared spectrum of the flue-cured tobacco leaf powder in the sample cup was scanned by a near...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com