Device and method for continuously measuring critical current of high-temperature superconducting tape

A critical current continuous, superconducting strip technology, used in measuring devices, measuring electrical variables, measuring current/voltage, etc., can solve the problem that the strip cannot be used continuously, the measurement value is inaccurate and unintuitive, and it is impossible to know the uniformity of the strip. problems such as performance and defects, to achieve the effect of good engineering practical value, convenient measurement and equipment cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

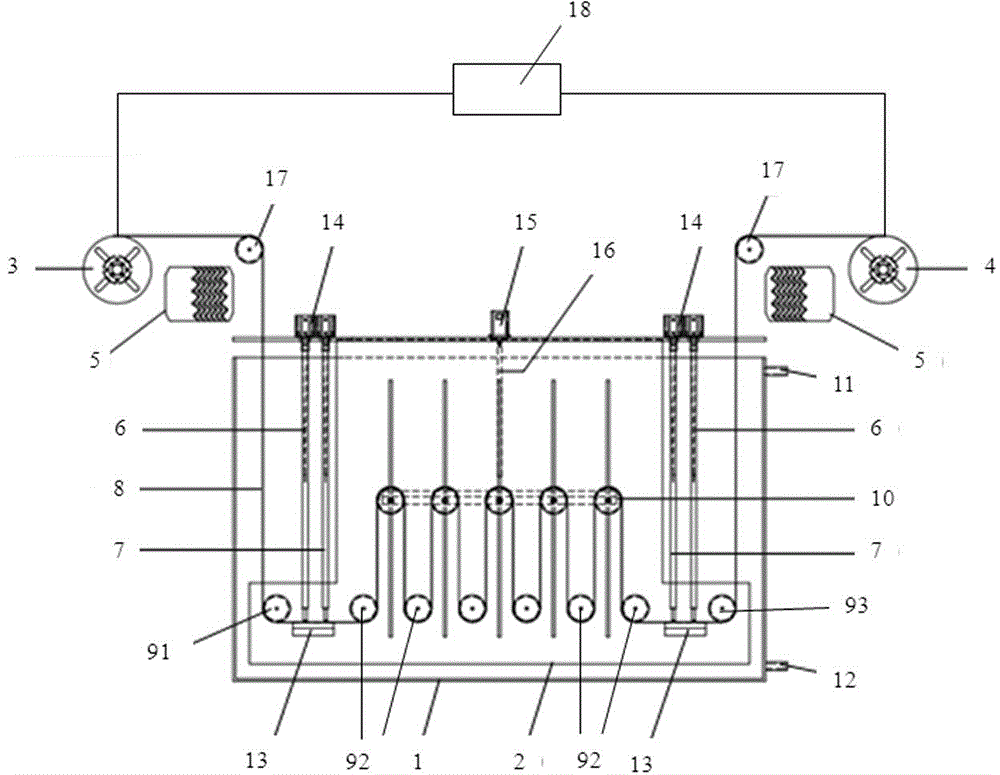

[0064] Step 1. Mount the superconducting tape 8 on the superconducting tape movement mechanism;

[0065] Step 2. The power device 15 drives the lifting mechanism 16 to move up and down, drives the driving wheel 10 to move, and adjusts the length of the superconducting strip 8 between the two measuring components to 1 meter;

[0066] Step 3. Add liquid nitrogen into the liquid nitrogen tank 1 from the liquid inlet 11, so that the liquid surface immerses the superconducting tape in the liquid nitrogen tank 1;

[0067] Step 4. Turn on the stepper motor to drive the superconducting tape 8 to move on the superconducting tape movement mechanism;

[0068] Step 5. Start the power mechanism 14, drive the current terminal 6 and the voltage terminal 7 down, and press the superconducting tape 8 on the bottom plate 13, so that the voltage terminal 7 and the current terminal 6 are in tight contact with the superconducting tape 8;

[0069] Step 6. Turn on the current source, voltage source and calcula...

Embodiment 2

[0074] The method of this embodiment is the same as that of embodiment 1, but the difference is: Step 2. The power device 15 drives the lifting mechanism 16 to move up and down, drives the driving wheel 10 to move, and adjusts the length of the superconducting strip 8 between the two measuring components. Is 2 meters;

[0075] This embodiment can realize the measurement of the critical current uniformity of superconducting tapes at a distance of 2 meters in kilometers.

Embodiment 3

[0077] The method of this embodiment is the same as that of embodiment 1, but the difference is: Step 2. The power device 15 drives the lifting mechanism 16 to move up and down, drives the driving wheel 10 to move, and adjusts the length of the superconducting strip 8 between the two measuring components. Is 5 meters;

[0078] This embodiment can realize the measurement of the critical current uniformity of the superconducting tape with a kilometer level of 5 meters apart.

[0079] The present invention can also measure the current low point or dead point in the superconducting strip to complete defect detection.

[0080] The device of the invention has simple structure, reasonable design and low manufacturing cost, and can realize continuous measurement of critical current of superconducting strips with a length of more than 1 meter, especially for kilometer-level superconducting strips. It can quickly and accurately measure the critical current of the superconducting tape and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com