A control method of radial ore-coke ratio in blast furnace material distribution process

A control method and technology of ore-coke ratio, which is applied in the control field of radial ore-coke ratio in the blast furnace material distribution process, can solve problems such as large deviation, inability to adjust, and insufficient calculation of material layer shape, so as to improve smelting intensity and molten iron output, The effect of increasing the amount of coal injection and increasing the amount of molten iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

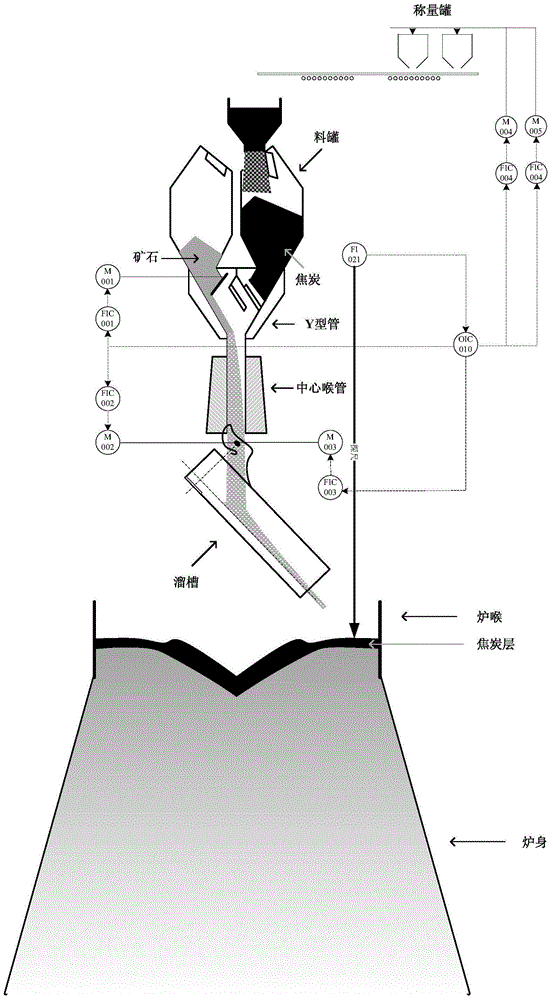

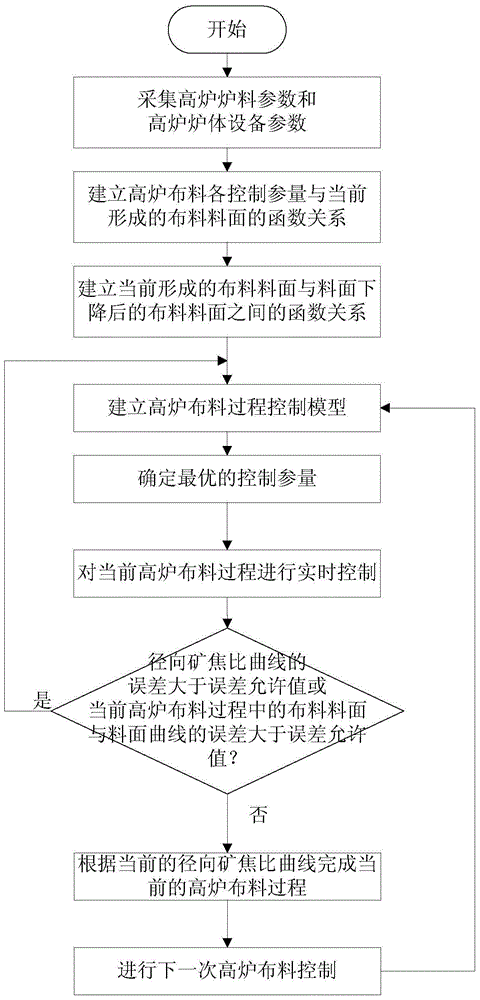

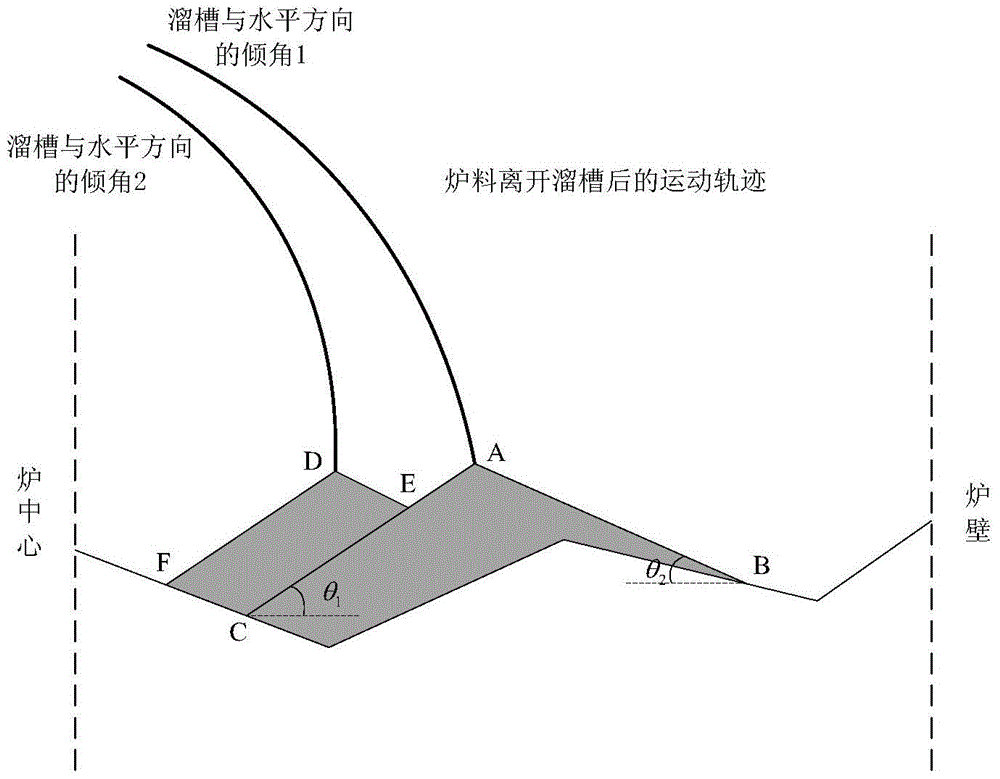

[0042] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0043] Considering the blast furnace production process, the influencing factors of the blast furnace material distribution and the distribution of the material surface in the furnace, combined with the actual production experience of the on-site operators, the condition factors in the production process of the blast furnace material distribution include: The center is symmetrical and evenly distributed; the charge is distributed in layers in the furnace, ignoring the overshoot phenomenon when the ore layer and the coke layer are mixed; the distribution time of each can is short, and the material level does not drop during the distribution process; the particle size is according to the composition and proportion of the charge Calculate the average value, ignoring the order of charge; set r from the center of the blast furnace 0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com