Telmisartan capsule and preparation method thereof

A kind of technology of telmisartan and capsule

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

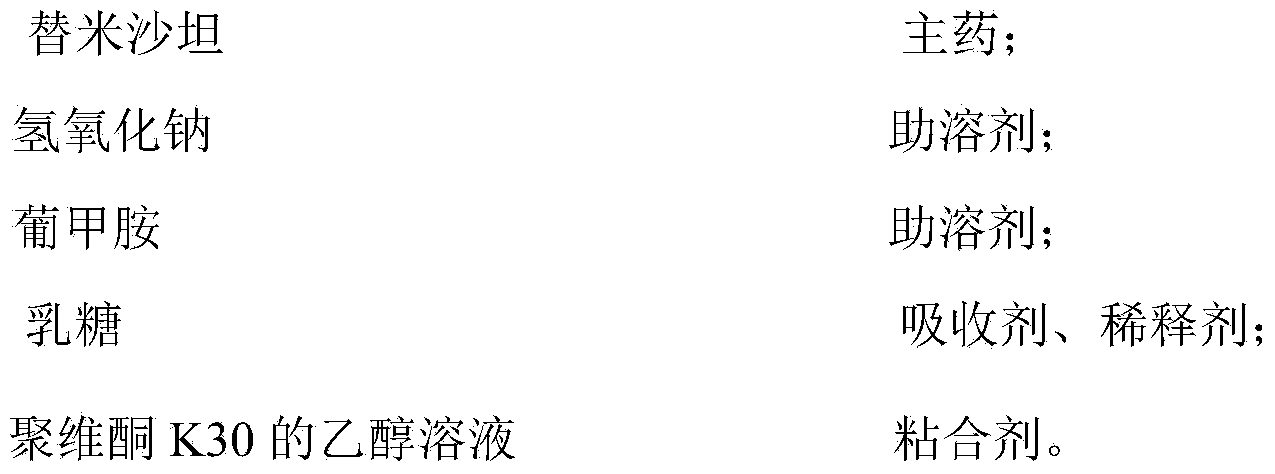

Method used

Image

Examples

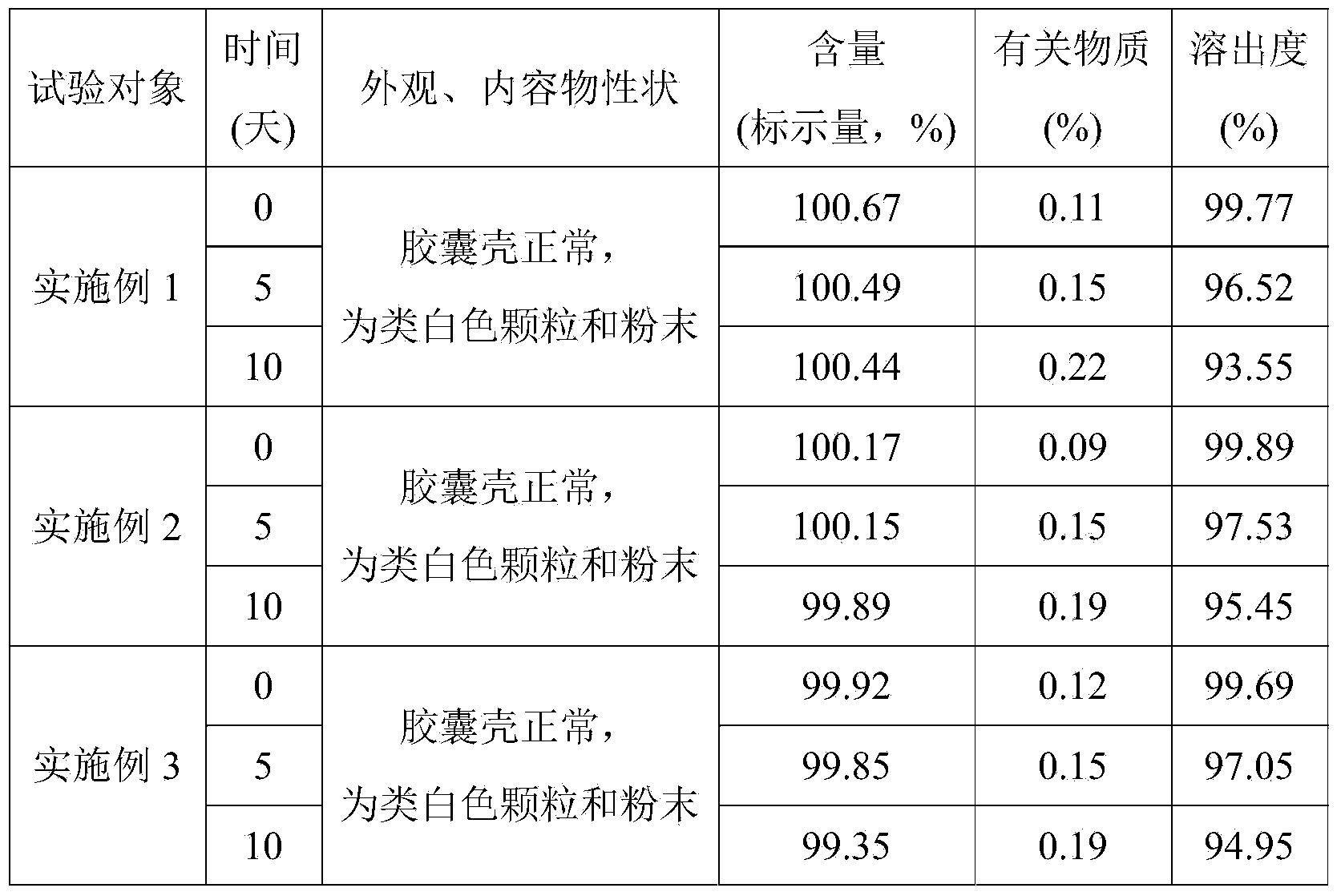

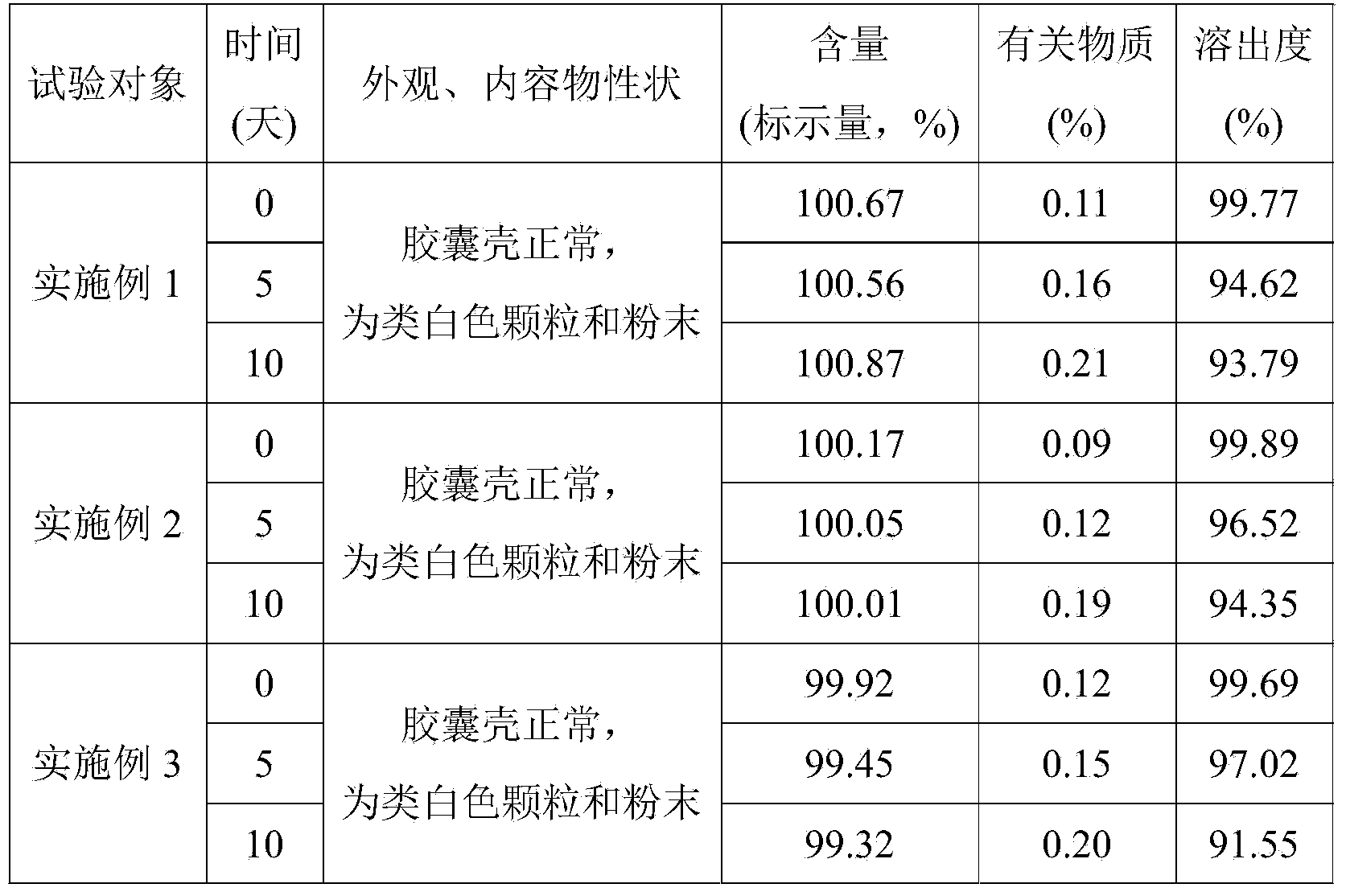

Embodiment 1

[0029] The telmisartan capsule of the present embodiment, every 1000 described telmisartan capsules comprise following components: telmisartan 40g, lactose 210g, sodium hydroxide 3.2g, meglumine 6.0g, polysaccharide Ethanol solution of Vitone K30 25ml.

[0030] The capsules are hard capsules.

[0031] The preparation method of the telmisartan capsule of the present embodiment comprises the following steps:

[0032] 1) Dissolve 3.2 g of sodium hydroxide and 6.0 g of meglumine in a small amount of 50% ethanol aqueous solution, add telmisartan, mix and grind to obtain mixture A;

[0033] 2) Add 210g of lactose to mixture A, mix and dry at 50°C for 60 minutes, then pulverize and pass through a 40-mesh sieve to obtain a mixed fine powder;

[0034] 3) Add 25ml of ethanol solution of povidone K30 with a mass concentration of 5% to the mixed fine powder obtained in step 2) to make a soft material, and pass through a 20-mesh sieve to make wet granules;

[0035] 4) After drying the w...

Embodiment 2

[0038] The telmisartan capsule of the present embodiment, every 1000 described telmisartan capsules comprise following components: telmisartan 40g, lactose 210g, sodium hydroxide 3.2g, meglumine 6.0g, polysaccharide Ethanol solution of Vitone K30 25ml.

[0039] The capsules are hard capsules.

[0040] The preparation method of the telmisartan capsule of the present embodiment comprises the following steps:

[0041] 1) Dissolve 3.2 g of sodium hydroxide and 6.0 g of meglumine in a small amount of 50% ethanol aqueous solution, add telmisartan, mix and grind to obtain mixture A;

[0042] 2) Add 210g of lactose to mixture A, mix and dry at 60°C for 30 minutes, then pulverize and pass through a 40-mesh sieve to obtain a mixed fine powder;

[0043] 3) Add 25ml of ethanol solution of povidone K30 with a mass concentration of 5% to the mixed fine powder obtained in step 2) to make a soft material, and pass through a 20-mesh sieve to make wet granules;

[0044] 4) After drying the w...

Embodiment 3

[0047] The telmisartan capsule of the present embodiment, every 1000 described telmisartan capsules comprise following components: telmisartan 40g, lactose 210g, sodium hydroxide 3.2g, meglumine 6.0g, polysaccharide Ethanol solution of Vitone K30 25ml.

[0048] The capsules are hard capsules.

[0049] The preparation method of the telmisartan capsule of the present embodiment comprises the following steps:

[0050] 1) Dissolve 3.2 g of sodium hydroxide and 6.0 g of meglumine in a small amount of 50% ethanol aqueous solution, add telmisartan, mix and grind to obtain mixture A;

[0051] 2) Add 210g of lactose to mixture A, mix and dry at 55°C for 45 minutes, then pulverize and pass through a 40-mesh sieve to obtain a mixed fine powder;

[0052] 3) Add 25ml of ethanol solution of povidone K30 with a mass concentration of 5% to the mixed fine powder obtained in step 2) to make a soft material, and pass through a 20-mesh sieve to make wet granules;

[0053] 4) After drying the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com