Spiral-wound film component

A roll-type membrane and module technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of reducing the discharge of concentrated water, increasing the cost pressure of energy recovery devices, and wasting water resources. Not easy to block, good performance, significant water saving effect, the effect of reducing running time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

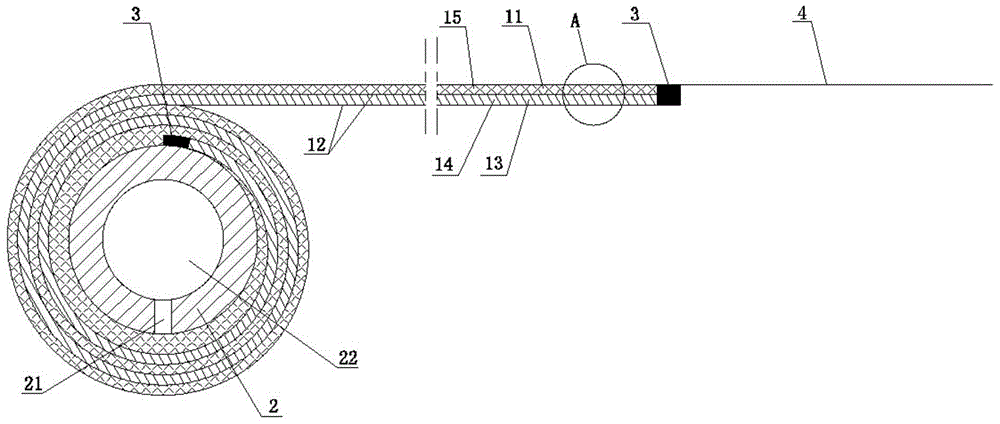

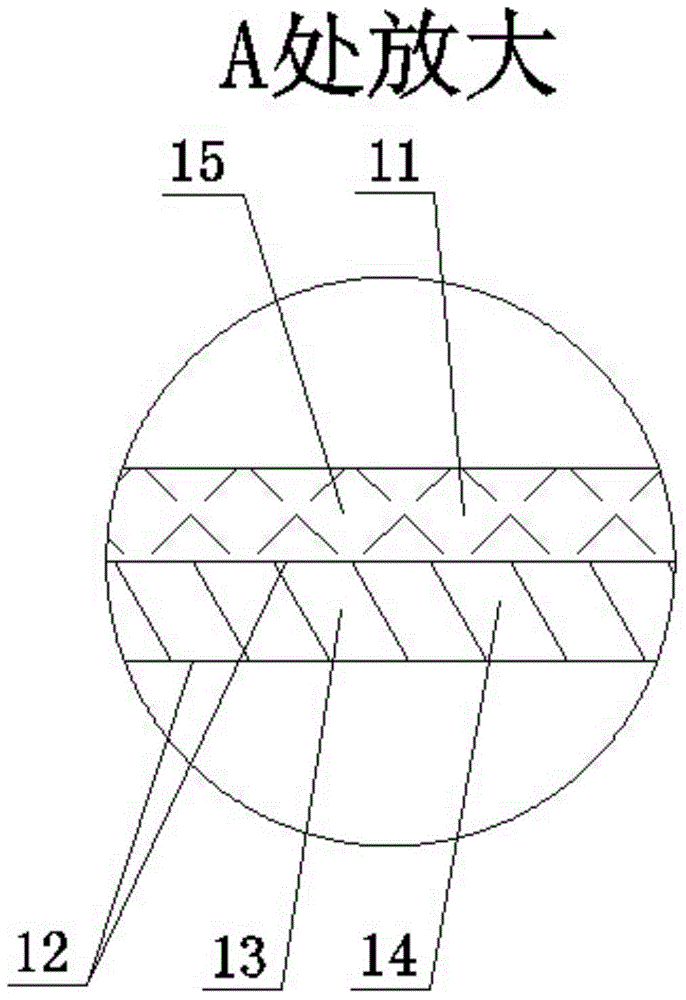

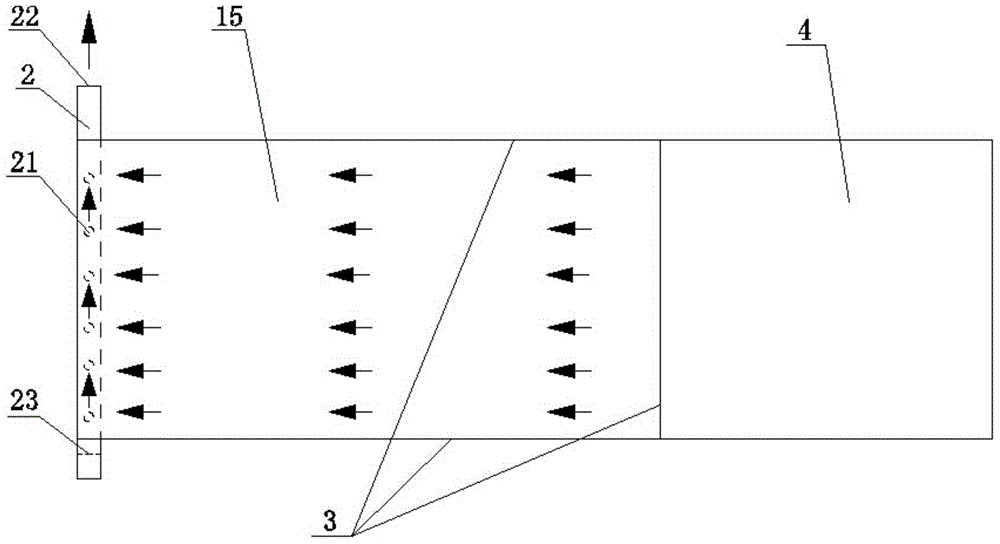

[0039] See Figure 1 to Figure 5 , the coiled membrane assembly of this embodiment includes a central water production pipe 2 and a water purification membrane group 1 wound on the central water production pipe 2 .

[0040] The water purification membrane set 1 includes a water production diversion net 11 , two plate filter membranes 12 and a raw water diversion net 13 . Between the inner surfaces of the two plate-shaped filter membranes 12 is a raw water flow channel 14 , and between the outer surfaces of the two plate-shaped filter membranes 12 is a produced water flow channel 15 . The raw water diversion net 13 is arranged in the raw water flow channel 14 . The permeate water diversion net 11 is arranged in the permeate water channel 15 . The central water production pipe 2 is provided with an axial inner hole, and the pipe wall of the central water production pipe 2 is provided with a plurality of water passage holes 21 communicating with the inner holes. One end of the...

Embodiment 2

[0054] See Figure 6 , this embodiment is basically the same as Embodiment 1, the difference is that: the two plate-shaped filter membranes 12 of the water purification membrane group 1 in this embodiment are formed by a long plate-shaped filter membrane at the center of the water production pipe 2 made by bending.

Embodiment 3

[0056] See Figure 7 , this embodiment is basically the same as Embodiment 1, the difference is that: this embodiment is provided with two sets of water purification diaphragm groups, and the two plate-shaped membranes of each group of water purification diaphragm groups are bonded near the central water production pipe. Closed and close to the central permeated water pipe is the permeated water diversion net or permeated water channel. The water production channels 15 in each water purification membrane group 1 are connected to the water passage holes 21 on the central water production pipe 2 . The two plate-shaped filter membranes 12 of each water purification membrane group 1 are parallel to the central water production pipe 2 and the sides close to the central water production pipe are sealed by adhesive 3 .

[0057] The water purification membrane group of the present embodiment can also be provided with more than two groups.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com