System for automatically cleaning inner pipe walls of heat exchanger

A technology for automatic cleaning and inner pipe wall, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of damage to the inner wall of the pipe, reduce the effective running time and service life of equipment, and achieve outage Long time, simple design, simple control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

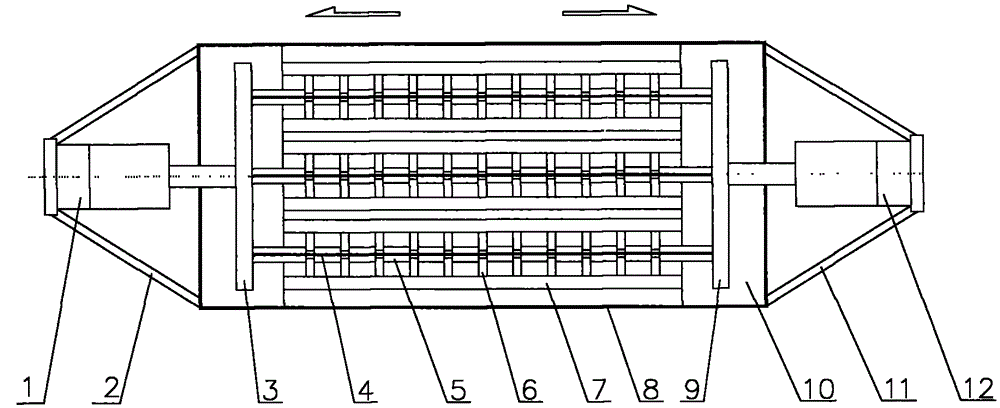

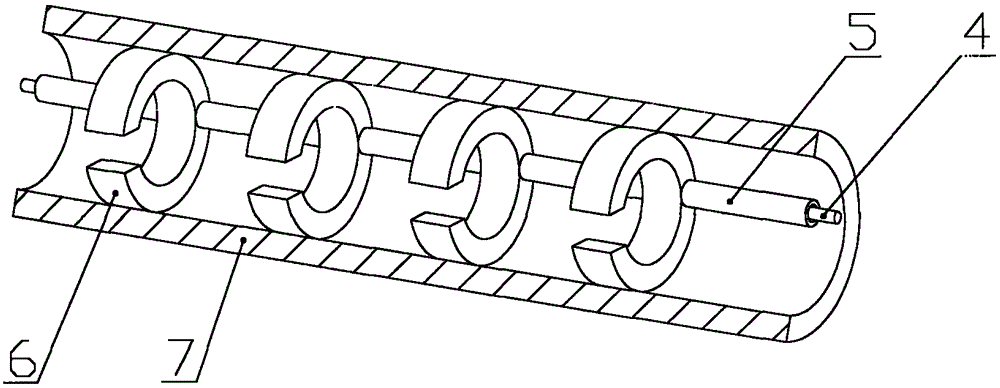

[0024] The heat exchange tube 7 of the heat exchanger is provided with a plurality of cleaning rings 6, and the cleaning rings are equidistantly separated by a thin casing 5, and a stainless steel wire 4 is used in the center to connect the cleaning rings and the thin casings in series. connected to form a cleaning ring group, and a set of cleaning ring groups connected in series by stainless steel wires are installed in each heat exchange tube.

[0025] The two ends of the stainless steel wire connected in series with the cleaning ring group are respectively fixed on the front movable end plate 3 and the rear movable end plate 9 at both ends of the heat exchanger. The front and rear movable end plates are respectively connected with the front push arm 1 and the rear push arm 12 at both ends, and the push arms are respectively fixed at the heat exchanger shell 8 through the front push arm bracket 2 and the rear push arm bracket 11 to play a role Supporting function, the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com