Grooved wheel clearance type welding feeding mechanism

A feeding mechanism and a gap-type technology, applied in the field of machinery, can solve the problems of difficult control of dead time, uneven feeding of copper materials, etc., and achieve the effect of simple structure, reasonable design and improved operating conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

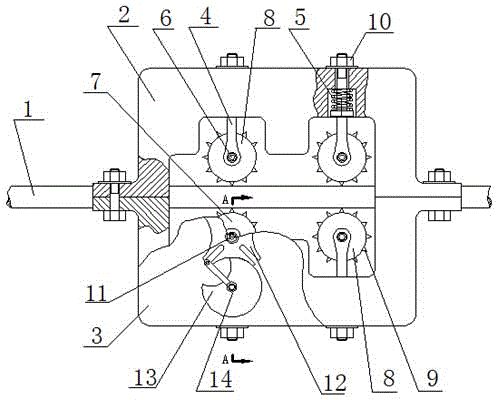

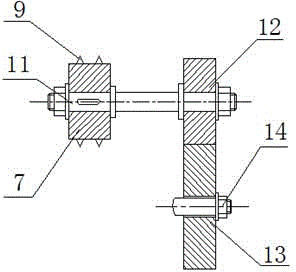

[0019] like figure 1 , figure 2 As shown, the slotted gap welding feed mechanism includes an upper frame 2, a lower frame 3, a telescopic shaft 4, a spring 5, a shaft 6, a driving wheel 7, a driven wheel 8, anti-skid teeth 9, nuts 10, a rotating shaft 11, Driven sheave 12, driving dial 13, transmission shaft 14, described upper frame 2 and lower frame 3 are all provided with rectangular grooves, and are provided with through holes in rectangular grooves, and described telescopic shaft 4 passes through Pass the through hole of the rectangular groove of the upper frame 2 or the lower frame 3, one end of which is connected with the driven wheel 8 through the shaft 6, and the other end is matched with the nut 10, and the spring 5 is arranged at the collar of the telescopic shaft 4 , the two ends of the rotating shaft 11 are respectively equipped with a driving wheel 7 and a driven sheave 12, and the driving dial 13 is assembled on the transmission shaft 14 and meshed with the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com