Continuous grout making machine used for fire preventing and extinguishing in coal mine

A technology of fire prevention and pulping machine, which is applied in clay preparation devices, chemical instruments and methods, clay processing equipment, etc., can solve the problem of large land occupation of soil dumps and mixing tanks, uncontrollable mud concentration, and utilization of pulping materials. Low efficiency and other problems, to achieve ideal pulping effect, conducive to continuous operation, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

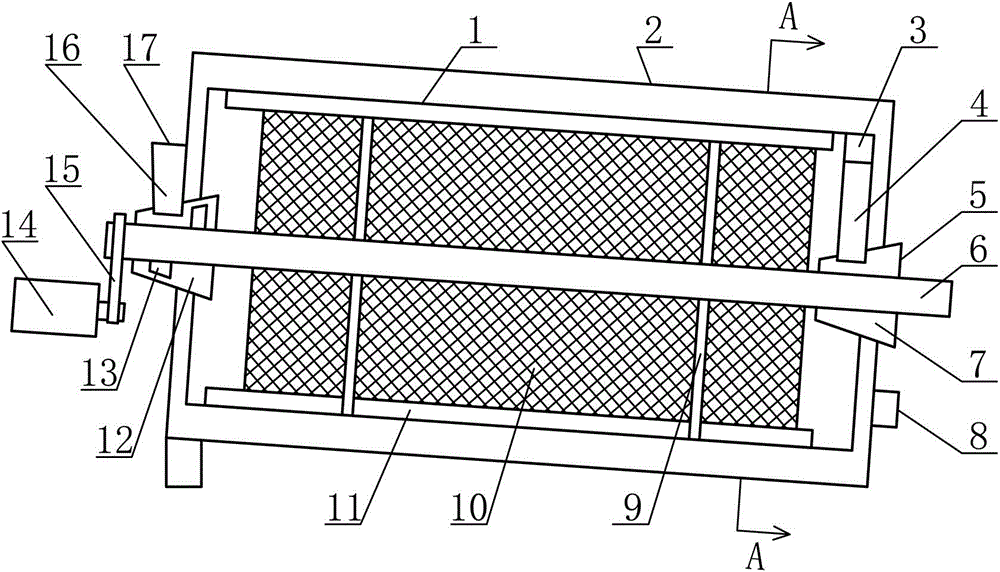

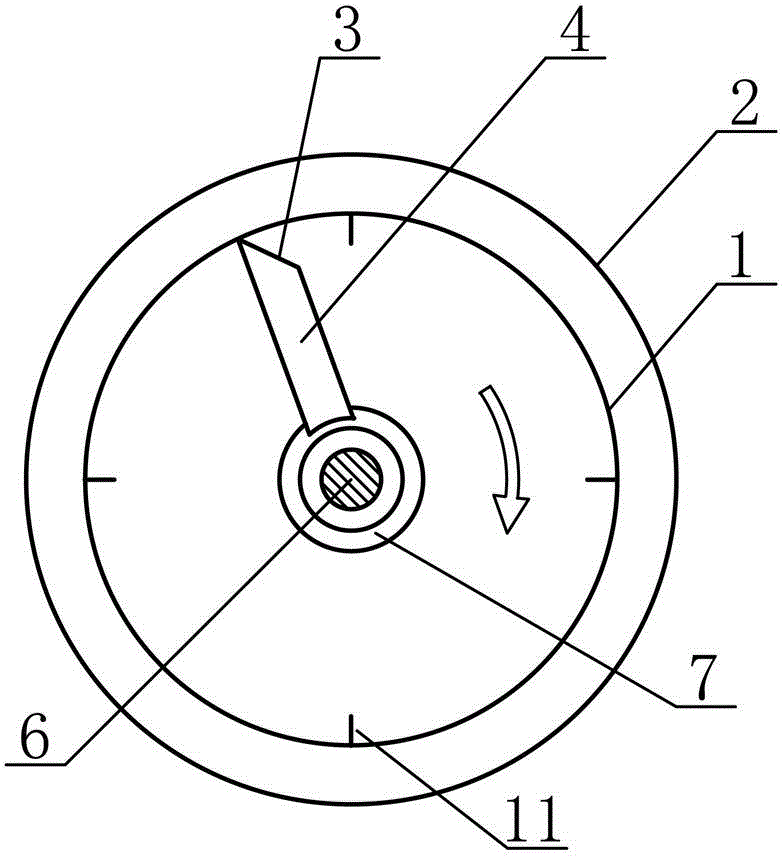

[0012] Such as figure 1 , figure 2 As shown, the continuous pulping machine for coal mine fire prevention has a slurry cylinder (2), a drum (1) contained in the slurry cylinder (2) and its driving device (14), the drum (1) passes through the web (9) ) Is fixedly connected with the central shaft (6), the slurry cylinder (2) and the drum (1) are installed obliquely, the feed inlet (17) is set at the higher end of the drum (1), and the slag outlet (5) is set at the drum ( 1) The other end. One end of the drum (1) near the feed port (17) is provided with a feed guide mechanism (16) and a feed buffer mechanism (12). The feed buffer mechanism (12) is in the shape of a truncated cone, and the feed buffer mechanism (12) is on the side Fixed to the center of the end face of the slurry cylinder (2) near the feed port (17), the small end of the feed buffer mechanism (12) extends to the outside of the slurry cylinder (2), and the large end of the feed buffer mechanism (12) passes through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com