Aseptic subpackaging equipment for medicine bottle for taking capsules accurately

A capsule and medicine bottle technology, which is applied in the field of capsule production equipment and aseptic packaging equipment, can solve the problems of insufficient cleanliness, sanitation, low counting accuracy, drug bacterial contamination, etc., achieve high bottling efficiency, reduce pollution, The effect of extending the validity period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

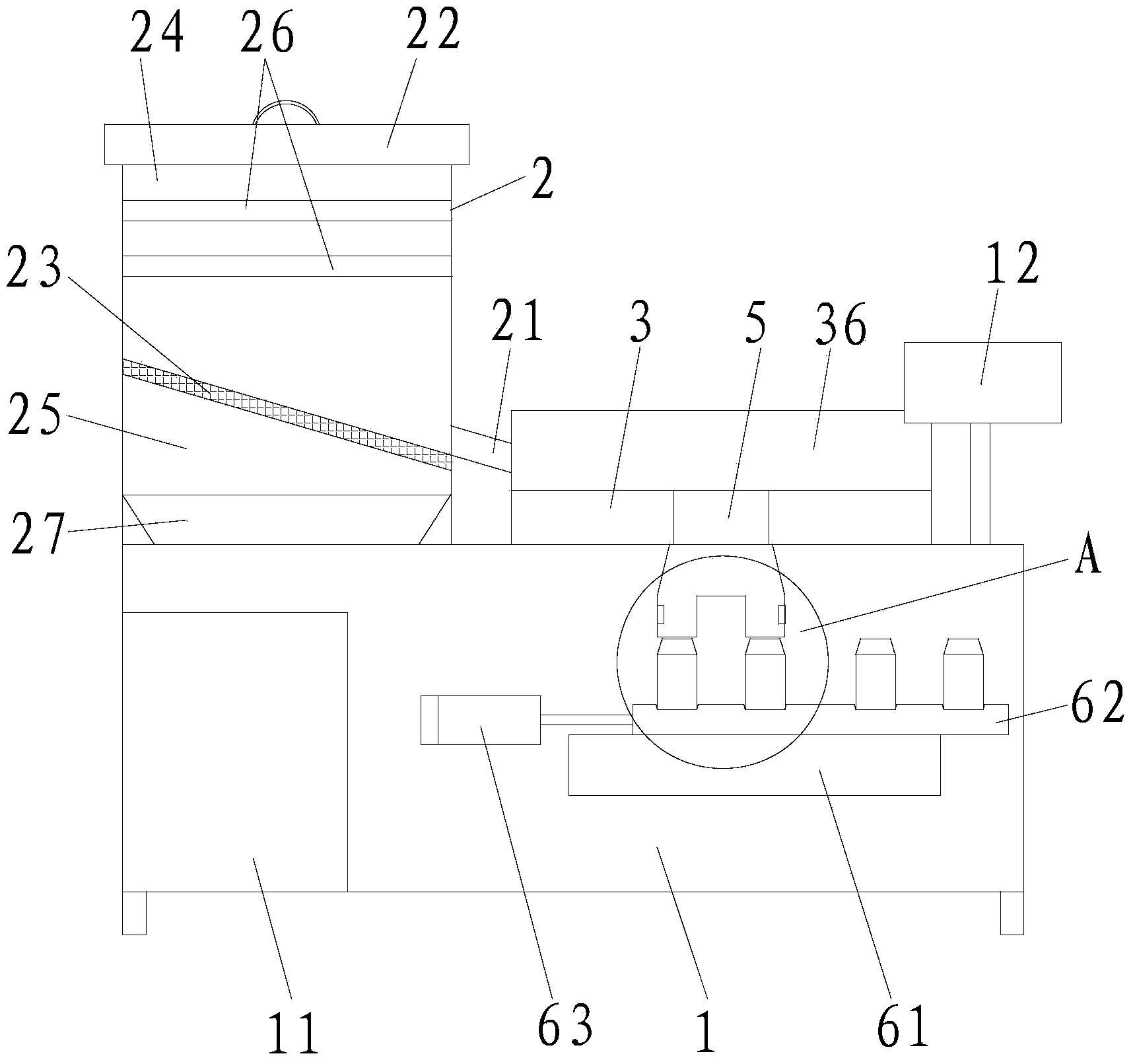

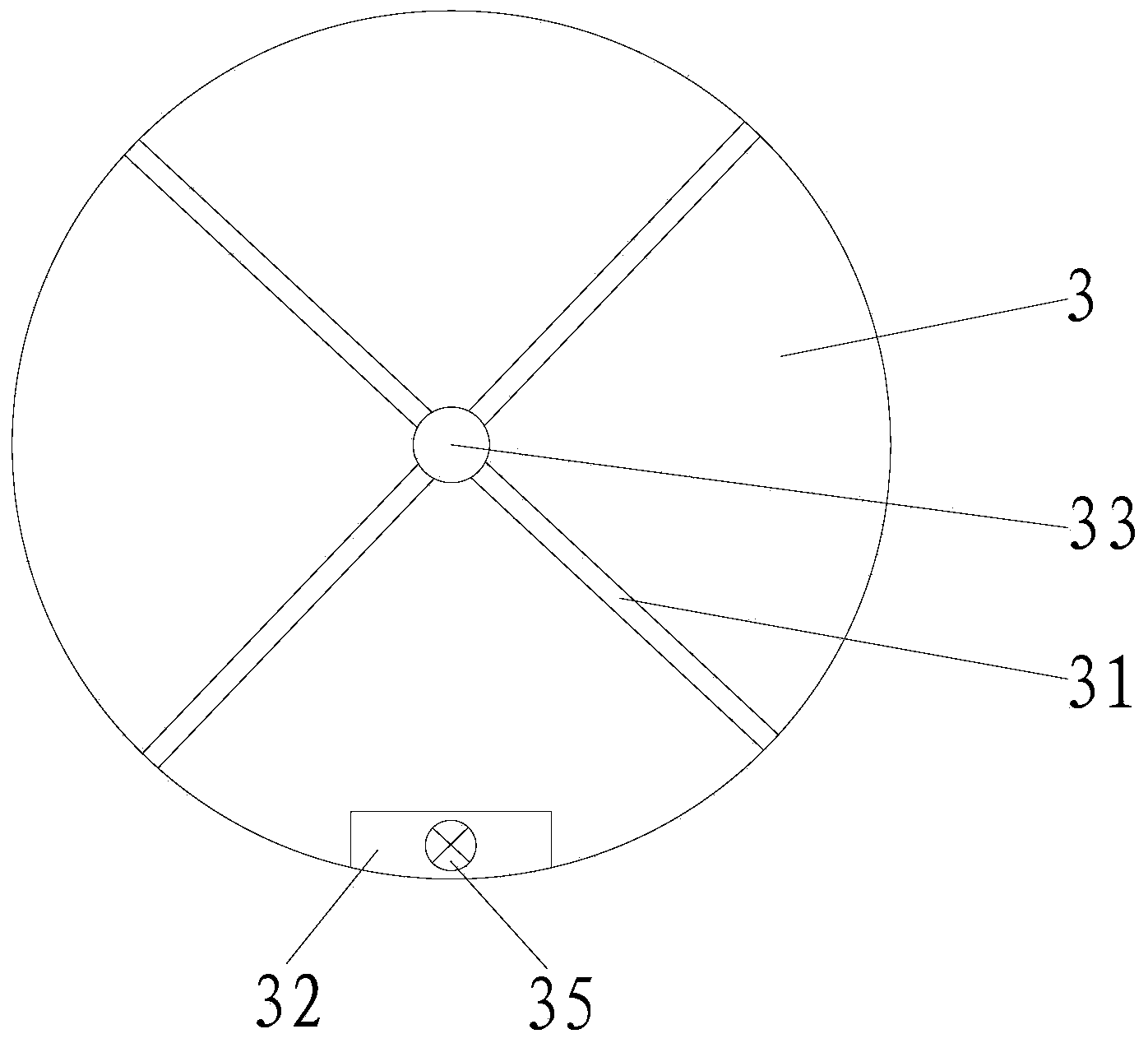

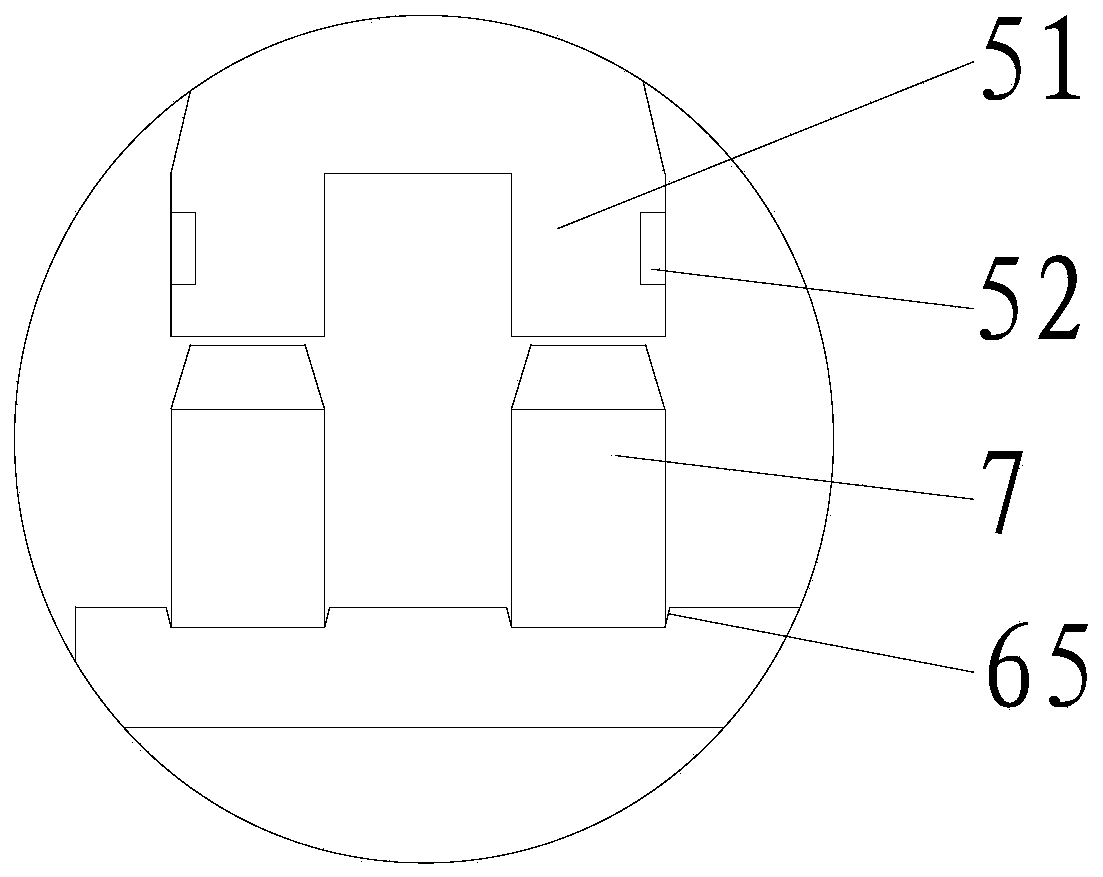

[0018] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , a kind of aseptic subpackaging equipment that adopts accurate capsule medicine bottle of the present invention, comprises fuselage 1, feed box 2, discharge plate 3, and control box 11 is installed in described fuselage 1, feed box 2 and The discharge tray 3 is installed on the fuselage 1, the first discharge port 21 is provided on the feed box 2, and several ultraviolet lamps 26 are installed in the feed box 2, the first discharge port 21 and the discharge tray 3 connected, a seal cover 36 is installed on the discharge tray 3, a number of scrapers 31 are installed in the discharge tray 3, a rotating shaft 33 is installed in the center of the discharge tray 3, and a plurality of scrapers 31 are evenly distributed on the rotating shaft 33. There is a second discharge port 32 on the material tray 3, a discharge valve 35 is installed on the second discharge port 32, a counting mechanism 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com