Non-phosphorus scale and corrosion inhibitor employing seawater as circulating cooling water, and preparation method thereof

A circulating cooling water, phosphorus-free anti-scaling technology, applied in chemical instruments and methods, water/sludge/sewage treatment, descaling and water softening, etc., can solve the problems of microbial algae overgrowth, seawater red tide, etc., and achieve high Corrosion and scale inhibition performance, good environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

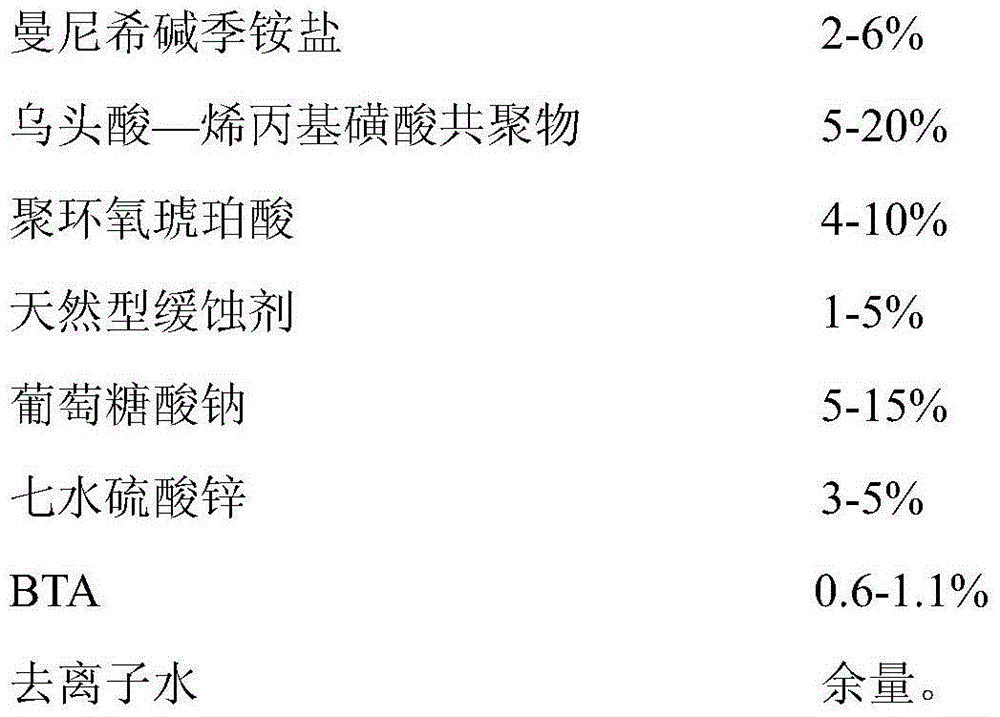

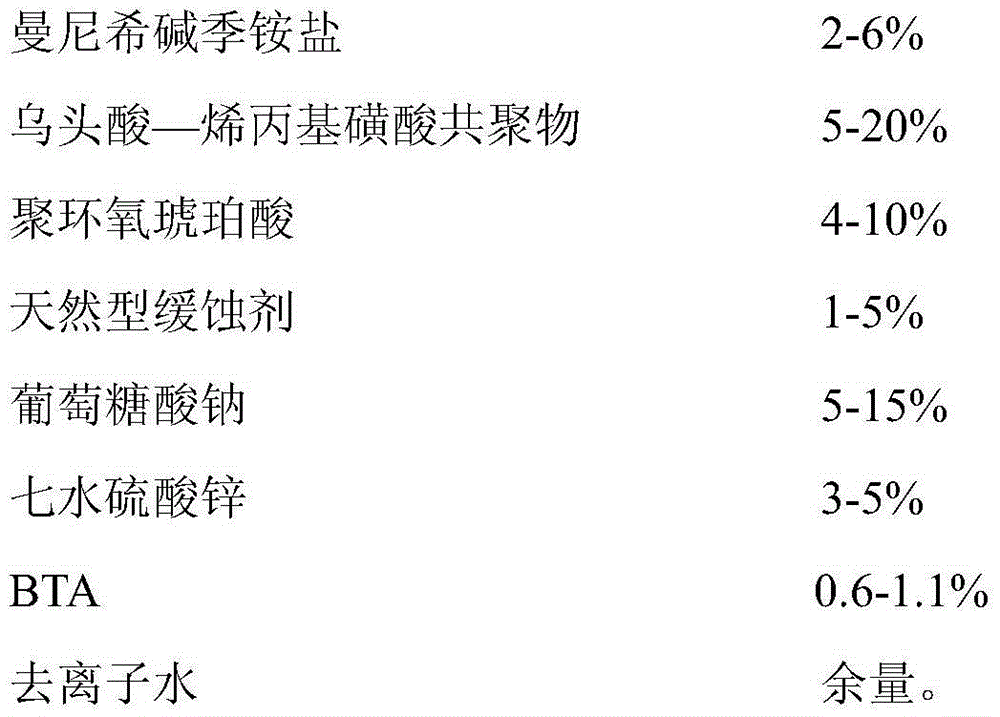

Method used

Image

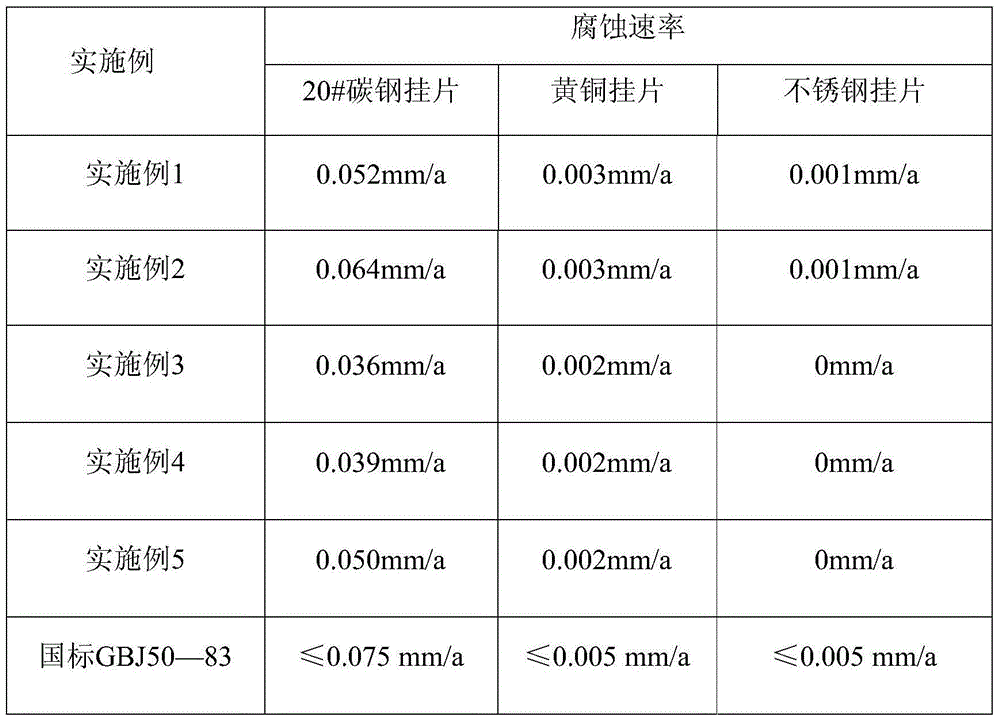

Examples

Embodiment 1

[0017] Prepare 100g of phosphorus-free seawater corrosion and scale inhibitor solution: weigh 15g of sodium gluconate, 4g of zinc sulfate heptahydrate, and 0.8g of BTA, add 42.8g of deionized water and stir for 30 minutes, then add 3g of Mannich base quaternary ammonium salt in sequence , 8g aconitic acid-allyl sulfonic acid copolymer, 4g polyepoxysuccinic acid, 1g mango peel extract, stirred for 10 minutes, finally added remaining deionized water to make the weight of the solution 100g, stirred for 20 minutes, that is The required phosphorus-free seawater corrosion and scale inhibitor solution is obtained.

Embodiment 2

[0019] Prepare 100g of phosphorus-free seawater corrosion and scale inhibitor solution: weigh 10g of sodium gluconate, 3g of zinc sulfate heptahydrate, and 0.6g of BTA, mix them, add 34.3g of deionized water to dissolve, then add 2g of Mannich base quaternary ammonium salt, 20g Aconitic acid-allyl sulfonic acid copolymer, 8g of polyepoxysuccinic acid, 5g of citrus peel extract, stirred for 12 minutes, and finally added the remaining deionized water to make the weight of the solution 100g, stirred for 20 minutes to obtain The required phosphorus-free seawater corrosion and scale inhibitor solution.

Embodiment 3

[0021] Prepare 100g of phosphorus-free seawater corrosion and scale inhibitor solution: weigh 8g of sodium gluconate, 5g of zinc sulfate heptahydrate, and 1.1g of BTA, mix them, add 40.3g of deionized water and stir for 25 minutes, then add 5.5g of Mannich base quaternary ammonium in sequence Salt, 5g aconitic acid-allyl sulfonic acid copolymer, 10g polyepoxysuccinic acid, 4g mango peel extract, stirred for 15 minutes, finally added remaining deionized water to make the weight of the solution 100g, stirred for 30 minutes, That is, the required phosphorus-free seawater corrosion and scale inhibitor solution is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com