Scale and corrosion inhibitor and production method and application thereof

A scale and corrosion inhibitor, acrylic acid technology, applied in the direction of chemical instruments and methods, descaling and water softening, special treatment goals, etc., can solve problems affecting the normal production of enterprises, equipment corrosion and scaling, equipment wear and tear, etc., to achieve guarantee Normal and good operation, good corrosion inhibition, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

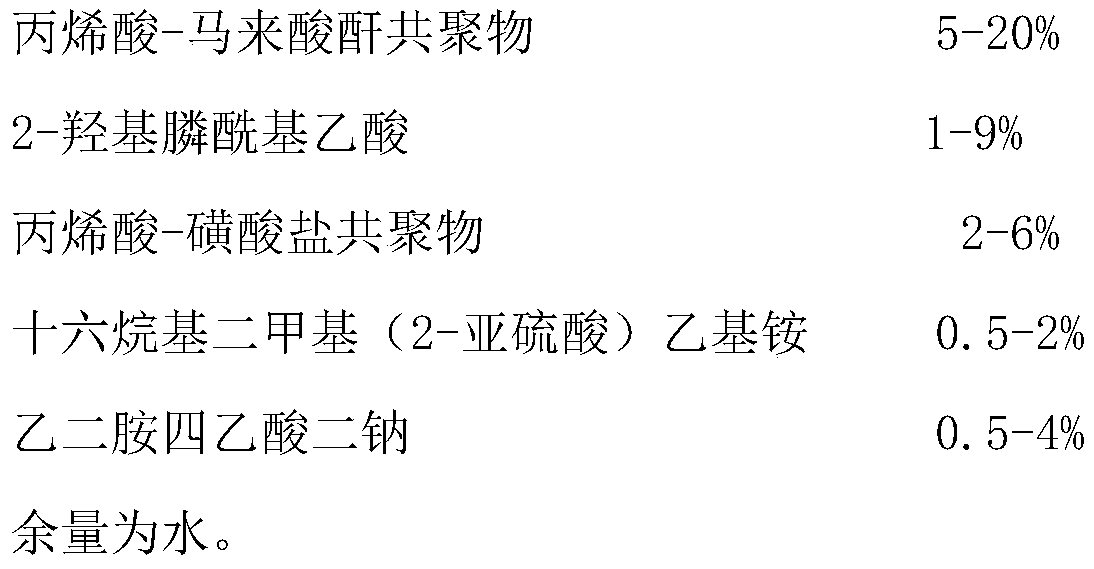

[0033] A scale and corrosion inhibitor, the mass percentage of each component is as follows:

[0034]

[0035] The acrylic acid-maleic anhydride copolymer used in this embodiment is an aqueous solution of acrylic acid-maleic anhydride copolymer with an active ingredient content of 50%; 2-hydroxyphosphonoacetic acid is a 2-hydroxyphosphonoacetic acid with an active ingredient content of 50%. Aqueous solution; acrylic acid-sulfonate copolymer is an aqueous solution of acrylic acid-sulfonate copolymer with an active ingredient content of 40%, hexadecyldimethyl(2-sulfite)ethylammonium and disodium edetate For pure products.

[0036] The preparation method comprises the following steps: 1) adding 30 kg of acrylic acid-maleic anhydride copolymer and 10 kg of 2-hydroxyphosphonoacetic acid into the container, adding water and stirring to make the acrylic acid-maleic anhydride copolymer and 2-hydroxyphosphonoacetic acid evenly mixed, Then add 12.5 kg of acrylic acid-sulfonate copol...

Embodiment 2

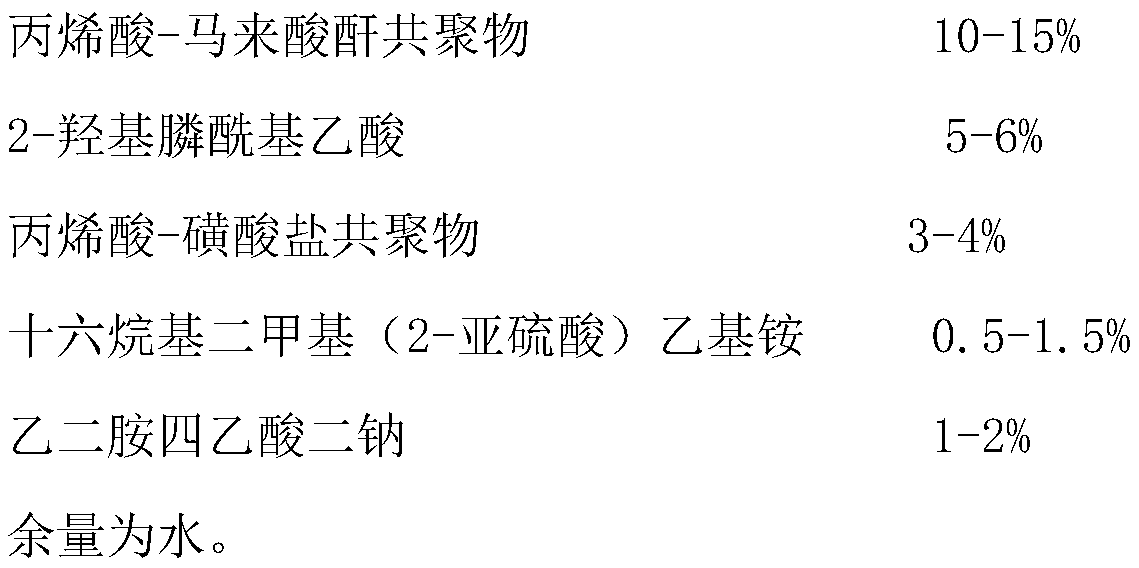

[0048] A scale and corrosion inhibitor, the mass percentage of each component is as follows:

[0049]

[0050] The preparation method is the same as in Example 1.

[0051] 1. Test and results

[0052] 1. Test conditions: Apply the scale and corrosion inhibitor of this example, the added concentration is 20mg / L, the circulating cooling system of an iron and steel enterprise has been continuously operated for 30 days, and the concentration of circulating water is 5-6 times higher. At the same time, the on-site For the scale and corrosion test of the hanging piece, the water quality of the test is on-site water, and the water quality is the same as Table 1.

[0053] 2. Test results:

[0054] During the experiment, during the entire 30-day operation period, the system operated stably and well without scaling and corrosion. At the end of the experiment, the surface of the heat exchanger in the on-site circulating cooling water system still maintained the original metallic lust...

Embodiment 3

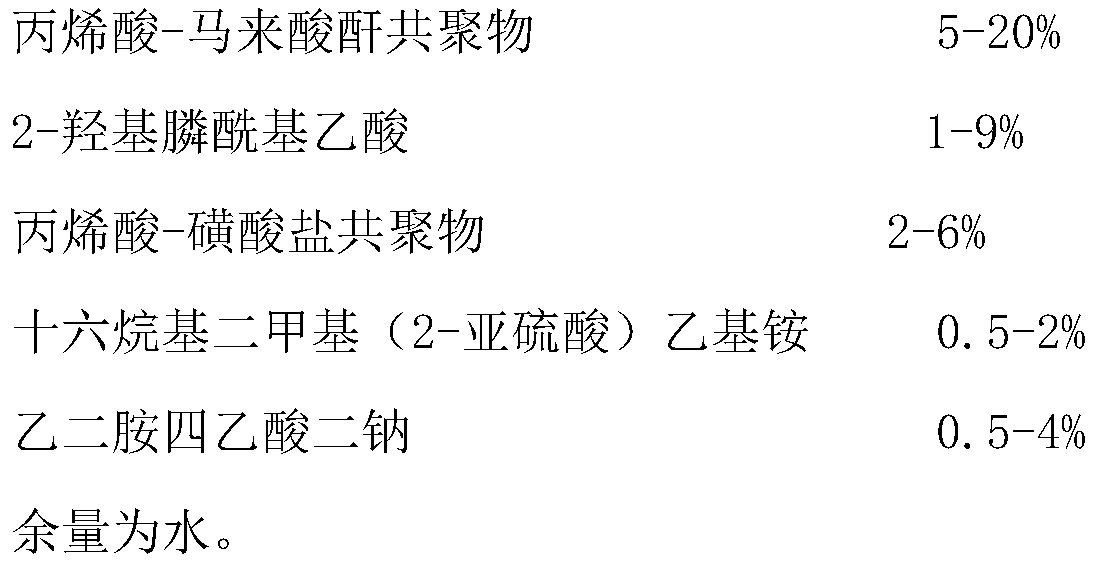

[0060] A scale and corrosion inhibitor, the mass percentage of each component is as follows:

[0061]

[0062] The preparation method is the same as in Example 1.

[0063] 1. Test and results

[0064] 1. Test conditions: Apply the scale and corrosion inhibitor of this example, the added concentration is 30mg / L, and the circulating cooling system of an iron and steel enterprise has been continuously operated for 30 days, and the concentration of circulating water is 7-8 times higher. At the same time, the on-site For the scale and corrosion test of the hanging piece, the water quality of the test is on-site water, and the water quality is the same as Table 1.

[0065] 2. Test results:

[0066] During the experiment, during the entire 30-day operation period, the system operated stably and well without scaling and corrosion. At the end of the experiment, the surface of the heat exchanger in the on-site circulating cooling water system still maintained the original metallic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com